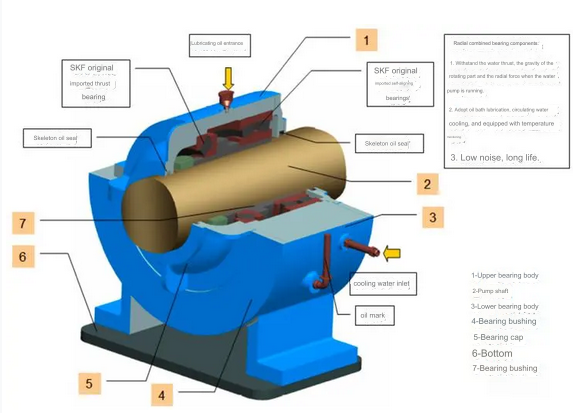

Pump bearing structure and lubrication method

The bearing structure and lubrication method of the pump are crucial for the normal operation and extended service life of the pump. In practical applications, the appropriate bearing type and lubrication method should be selected according to the specific working conditions and requirements of the pump, and regular maintenance and inspection should be carried out to ensure the stable operation of the pump.

The following is a brief overview of the bearing structure and lubrication method of the pump:

1. Bearing structure

The bearing structure of the pump is usually designed according to factors such as the type of pump, load size and speed. Common bearing types include rolling bearings and sliding bearings. Rolling bearings such as ball bearings and roller bearings have high-speed capabilities and low friction, and are suitable for small and medium-sized pumps and light and medium loads. Sliding bearings are suitable for pumps with heavy loads, high speeds or special working conditions.

In centrifugal pumps, common bearing types include single-row deep groove ball bearings, single-row angular contact ball bearings and double-row angular contact ball bearings. These bearings are precisely designed and installed to ensure that the pump shaft remains stable at high-speed rotation, while being able to withstand various loads from the pump body and fluid.

2. Lubrication method

There are various bearing lubrication methods for pumps, mainly including grease lubrication, oil lubrication and pressure oil lubrication.

Grease lubrication: Suitable for low-voltage motors and light and medium-load pumps. Grease lubrication is simple to operate and easy to maintain, but it is necessary to pay attention to regular replenishment and replacement of grease to ensure the normal operation of the bearing.

Oil lubrication: For medium and heavy-load centrifugal pumps and rotor pumps, oil lubrication is a common lubrication method. Oil lubrication can provide better cooling and cleaning effects, which helps to extend the life of the bearing. The oil lubrication system usually includes components such as an oil tank, an oil pump, and an oil filter to ensure that the lubricating oil can be continuously and stably supplied to the bearing.

Pressure oil lubrication: Under high speed, heavy load or special working conditions, the pressure oil lubrication system can provide a more reliable lubrication effect. The system delivers high-pressure lubricating oil to the bearing part through an oil pump, and keeps the lubricating oil clean and at a suitable temperature through components such as coolers and filters. In addition, the pressure oil lubrication system also has alarm and shutdown functions, which can promptly issue an alarm and shut down for protection when the lubricating oil pressure is insufficient or the system fails.