Pump component durability and replacement cycle

The durability of pump components is closely related to factors such as its material, design, manufacturing process and operating conditions. The durability of different components varies greatly, so their replacement cycles are also different. The following is a general overview of the durability and replacement cycle of the main pump components:

Impeller: As a key component in the pump, the impeller is responsible for pressing the liquid into the pipeline. Its durability is affected by factors such as liquid type, flow rate, temperature and pump operating conditions. Generally speaking, the life of the impeller is about 1 to 2 years, but the specific life needs to be judged based on actual use. If the impeller has problems such as wear, cracks or imbalance, it should be replaced in time to avoid affecting the operating efficiency and safety of the pump.

Bearing: The bearing plays a supporting and friction-reducing role in the water pump. Its durability is also affected by many factors, such as load size, speed, lubrication condition, etc. Under normal circumstances, the life of the bearing is 2 to 3 years. However, under harsh operating conditions, the life of the bearing may be shortened. Therefore, it is essential to regularly check the wear of the bearing and replace the damaged bearing in time to maintain the normal operation of the pump.

Sealing ring: The main function of the sealing ring is to prevent the mixing of water inside and outside the pump and to prevent leakage. Its durability is affected by factors such as the properties of the medium, temperature, and pressure. The life of the sealing ring is generally about 2 to 3 years. However, in actual use, if the sealing ring is found to be leaking seriously or worn excessively, it should be replaced in time to avoid adverse effects on the performance and safety of the pump.

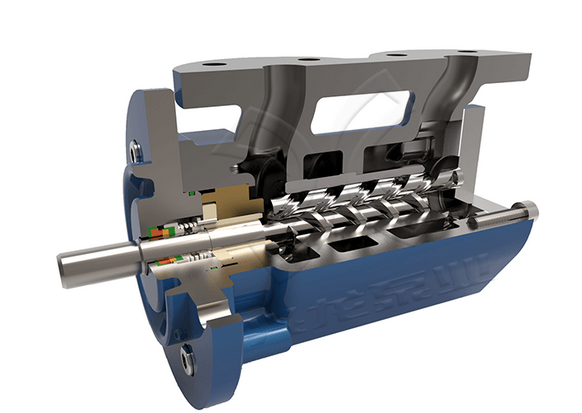

Other parts: In addition to the above-mentioned main parts, the pump also includes parts such as the pump housing, shaft, and coupling. The durability and replacement cycle of these parts also vary, and they need to be judged according to the type, specification, and use conditions of the pump.

In summary, the durability and replacement cycle of pump parts are affected by many factors. It is recommended that users strictly follow the instructions for maintenance and regularly check and replace damaged parts. At the same time, pay attention to improving the operating conditions of the pump to improve the durability of parts and extend the replacement cycle.