Pump cooling system design and common problems

The design and maintenance of the cooling system of the pump is a key link to ensure the long-term stable operation of the pump. When designing the cooling system of the pump, the following aspects need to be considered:

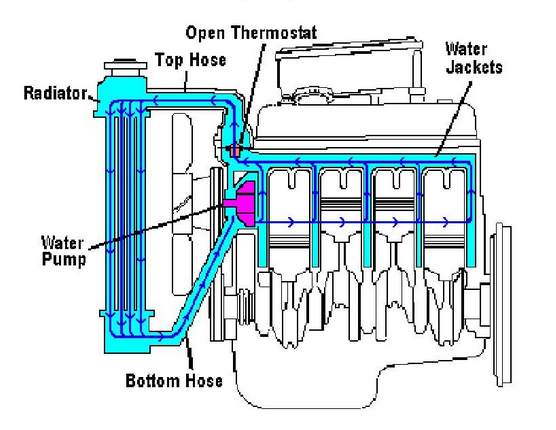

1. Selection of cooling method: According to the type of pump and the operating environment, select a suitable cooling method, such as air cooling, water cooling or mixed cooling. For pumps running at high temperature and high load, water cooling is usually selected to use cooling water to remove the heat generated by the pump body and bearings.

2. Cooling medium and flow rate: Select a suitable cooling medium, such as clean water, circulating water or specific coolant, and ensure that the flow rate of the cooling medium is sufficient to effectively remove the heat. At the same time, the temperature, pressure and other parameters of the cooling medium need to be considered to ensure that it operates within a safe range.

3. Cooling pipeline layout: Reasonably design the layout of the cooling pipeline to ensure that the cooling medium can flow evenly and efficiently through the pump body and the parts that need to be cooled. The pipeline should avoid being too long, too thin or having sharp bends to reduce resistance loss and ensure the cooling effect.

4. Heat exchanger design: For water-cooled pumps, the design of the heat exchanger is crucial. It is necessary to select the appropriate type and specification of the heat exchanger according to the heat generation and cooling requirements of the pump, and optimize its structure to improve the heat exchange efficiency.

Common problems and solutions:

1. Insufficient cooling: It is manifested as the temperature of the pump body is too high, which may be due to insufficient cooling medium flow, pipe blockage or reduced heat exchanger efficiency. It is necessary to check the components of the cooling system, clean the blockage, and replace the heat exchanger or increase the cooling medium flow if necessary.

2. Leakage problem: Leakage in the cooling system will affect the cooling effect and may damage the equipment. It is necessary to regularly check the pipe joints and seals, and repair or replace damaged parts in time.

3. Noise and vibration: Noise and vibration during the operation of the cooling system may be due to unreasonable pipe layout, too fast cooling medium flow rate or pump body problems. It is necessary to optimize the pipe layout, adjust the cooling medium flow rate and check whether the pump body is faulty.