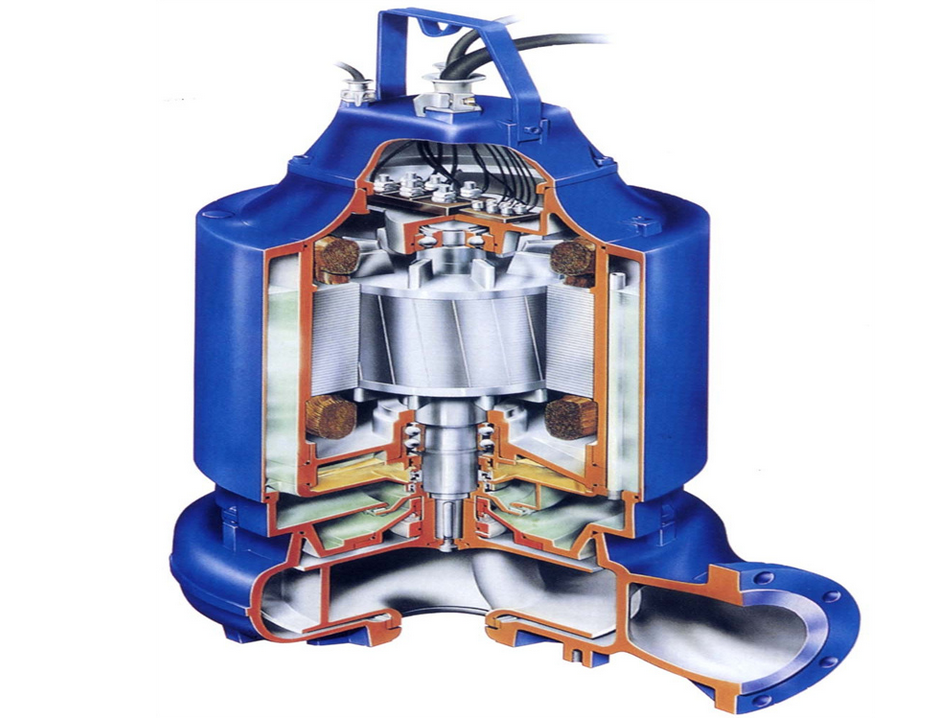

Rotating parts of sewage pumps

The rotating parts of the sewage pump mainly include the following key parts:

1. Impeller

Core function: The impeller is the core component of the sewage pump, which is responsible for sucking sewage from the inlet and pushing the sewage out through the power of rotation.

Material and characteristics: The impeller is usually made of cast iron or stainless steel to cope with the corrosive and abrasive environment in sewage. These materials have strong corrosion resistance and wear resistance to ensure long-term and efficient operation.

Type: Impellers are generally divided into closed and semi-open types. Semi-open impellers have a longer service life and can more effectively treat sewage containing sand and solid particle pollutants.

2. Pump shaft

Function: The pump shaft is the main component for transmitting mechanical energy. It is connected to the motor with the help of a coupling to transmit the torque of the motor to the impeller.

Structure and material: The design of the pump shaft needs to meet the requirements of strength and stiffness to withstand the force and torque generated when the impeller rotates. Its material is usually selected from wear-resistant and corrosion-resistant materials to ensure stable operation in harsh working environments.

3. Bearing

Function: The bearing is a component that is sleeved on the pump shaft to support the pump shaft. It is divided into two types: rotating bearings and sliding bearings. Their main function is to reduce the friction and wear of the pump shaft during rotation and ensure the stable operation of the pump shaft.

Lubrication and maintenance: Bearings need to be lubricated and maintained regularly to ensure their normal operation. Rotating bearings usually use butter as a lubricant, while sliding bearings use transparent oil. During the lubrication process, the amount of lubricant needs to be controlled to avoid problems caused by too much or too little.

4. Mechanical seal

Function: Mechanical seal is an important part of the pump, and it mainly plays an important role in preventing liquid leakage in the pump body. It achieves the sealing effect by forming a tight, wear-free contact between the two surfaces during operation.

Type and selection: Mechanical seals are divided into single-end mechanical seals and double-end mechanical seals. The latter has better sealing performance, but the price is relatively higher. When choosing a mechanical seal, it is necessary to determine the appropriate type and specification according to the working environment and requirements of the pump.

In summary, the coordinated work of the rotating parts of the sewage pump ensures the normal operation and efficient operation of the sewage pump. During use, these parts need to be inspected and maintained regularly to ensure their performance and life.