Screw pump operating condition analysis

Analyzing the working condition of a screw pump is a comprehensive process involving multiple considerations. The following are methods for analyzing the working condition of a screw pump from different angles:

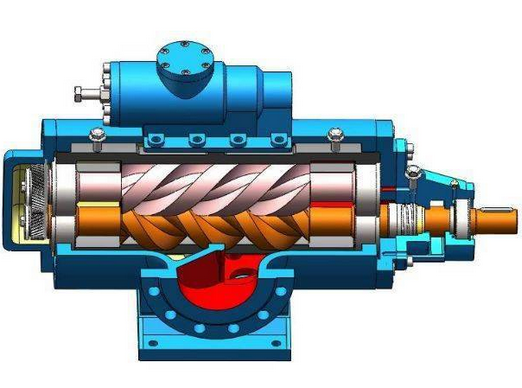

1. Understanding the working principle

First, it is necessary to have a deep understanding of the working principle of a screw pump. A screw pump is a centrifugal pump that uses a rotating screw to suck in and push out liquid. It consists of one or more screws and one or more screw grooves. When the screw rotates, the screw groove moves with it, pushing the liquid to the pump outlet. At the same time, the rotation of the screw also forms a negative pressure, allowing more liquid to be sucked in.

2. Monitoring of working parameters

Flow measurement:

The working condition of the pump is determined by measuring the flow rate at the inlet and outlet. Under normal circumstances, the inlet and outlet flows should be balanced. If the inlet flow rate is greater than the outlet flow rate, it may mean that the pump's performance has decreased or there is a blockage; if the outlet flow rate is greater than the inlet flow rate, it may mean that the pump's performance has increased or there is a leak.

Pressure measurement:

Measuring the pressure at the inlet and outlet is also an important means of determining the working condition of the pump. Under normal circumstances, the inlet pressure should be higher than the outlet pressure. If the inlet pressure is lower than the normal range, it may mean that the inlet pipe is blocked or the suction performance of the pump is reduced; if the outlet pressure is lower than the normal range, it may mean that the outlet pipe is blocked or the discharge performance of the pump is reduced.

Temperature measurement:

The temperature difference between the inlet and outlet can also reflect the working status of the pump. Under normal circumstances, the inlet and outlet temperatures should not differ much. If the inlet temperature is significantly higher than the outlet temperature, it may mean that there is leakage or backflow in the pump; if the outlet temperature is significantly higher than the inlet temperature, it may mean that there is blockage or component wear in the pump.

Sound and vibration measurement:

The working status of the pump is determined by measuring the sound and vibration when the pump is running. Under normal circumstances, the pump should run smoothly, without noise and vibration. If the pump has noise or vibration, it may mean bearing damage, unbalanced pump shaft or other component failure.

Current method:

By testing the working current of the drive motor, the pump condition is diagnosed according to the working current size. When the working current is close to the motor no-load current, it may indicate that there is no displacement or the oil casing is not connected (such as the sucker rod is broken); when the current is close to the normal operating current but the displacement is very small, it may indicate that the oil pipe is leaking or the pump stator rubber is seriously worn; when it is significantly higher than the normal operating current, it may indicate that the oil is thick or wax is seriously deposited, etc.

Pressure holding method:

Close the Christmas tree back pressure gate to hold the pressure, observe the wellhead back pressure and casing pressure changes to diagnose the downhole pump condition. If the back pressure does not rise and is different from the casing pressure, it may indicate that there is no displacement or the sucker rod is broken; if the back pressure is close to the casing pressure, it may indicate that the oil casing is connected or the stator rubber is falling off, etc.

3. Appearance and liquid level inspection

Appearance inspection:

Observe the appearance of the pump to check for leaks, seepage, odor and obvious wear. These phenomena may directly reflect the working status and potential problems of the pump.

Liquid level measurement:

The working status of the pump is judged by measuring the liquid level difference at the inlet and outlet of the pump. Under normal circumstances, the inlet liquid level should be lower than the outlet liquid level. If the inlet liquid level is higher than the outlet liquid level, it may mean that the inlet pipeline is blocked or liquid is refluxed.

4. Comprehensive analysis and diagnosis

Comprehensive analysis of the above monitoring and inspection results can comprehensively evaluate the working condition of the screw pump. If abnormal phenomena are found or data deviates from the normal range, corresponding measures should be taken in time to check and repair to ensure the normal operation of the screw pump and extend its service life.