Selection and usage skills of pump fans

Selection and Usage Tips for Pump and Fan

The selection and usage of pump and fan are crucial for ensuring efficient and stable operation of the equipment. Here are detailed explanations from both aspects of selection and usage:

I. Selection of Pump and Fan

Understand the Needs: Before selecting a pump or fan, it is important to clarify the specific requirements for the equipment, including the nature of the fluid to be transported (e.g., clean water, sewage, corrosive liquids, etc.), flow rate, lift (or air pressure), and other parameters.

Type Selection:

For pumps: Depending on the nature of the fluid to be transported, different types of pumps can be chosen, such as centrifugal pumps, self-priming pumps, pipeline pumps, etc. Among them, centrifugal pumps are suitable for water supply systems, industrial systems, etc.; self-priming pumps are used for transporting clean water, irrigation, water circulation, etc.; pipeline pumps are suitable for transporting liquids mixed with solid particles.

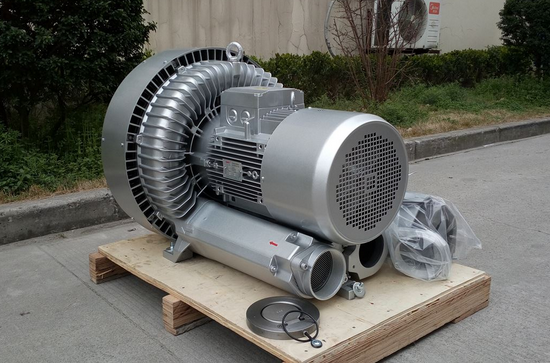

For fans: There are various types of fans, including centrifugal fans, axial fans, mixed-flow fans, etc. Centrifugal fans are mainly used for ventilation, air supply, pressurization, etc.; axial fans have the characteristics of large flow rate and low air pressure, suitable for ventilation, air conditioning, and other fields.

Performance Parameters: When selecting a pump or fan, attention should be paid to its performance parameters, such as flow rate, lift (or air pressure), efficiency, noise, and vibration. These parameters will directly affect the operation effect and energy consumption of the equipment.

Quality and Brand: Choosing well-known brands and reliable quality pump and fan products can ensure the performance and lifespan of the equipment.

II. Usage Tips for Pump and Fan

Preparation before Startup:

Check if the motor rotation direction is correct, ensuring the motor rotates clockwise.

Open the exhaust valve to allow the liquid to fill the entire pump body and then close the exhaust valve.

Check if all parts of the pump and fan are normal, ensuring no looseness or leakage.

For high-temperature pumps and fans, preheating should be carried out before operation, and the heating rate should be controlled within 50℃/hour.

Startup and Operation:

Fully open the inlet valve and close the outlet valve.

Start the motor and observe if the pump and fan are operating normally.

Adjust the opening of the outlet valve to control the flow rate or air pressure, ensuring the equipment operates at the rated point listed in the performance parameter table.

Check the leakage of the shaft seal, and ensure that the leakage of the mechanical seal is less than 3 drops per minute.

Regularly check the temperature rise of the motor and bearings to ensure they do not exceed the specified value.

Shutdown and Maintenance:

For high-temperature pumps and fans, the temperature should be reduced before shutdown, and the cooling rate should be controlled within 10℃/minute.

Close the outlet valve and stop the motor.

Close the inlet and outlet valves. If the equipment is parked for a long time, the liquid inside the pump should be drained.

Regularly maintain the pump and fan, including cleaning, inspection, and replacement of wear parts.

Through the introduction of the above selection and usage tips, I believe readers can better select and use pump and fan equipment to ensure efficient and stable operation.