Selection of central air conditioning circulation centrifugal water pump

The selection of central air conditioning circulating centrifugal water pump is a comprehensive process, and multiple factors need to be considered to ensure that the water pump can smoothly cooperate with the entire central air conditioning system. The following is a detailed selection guide:

1. Preparation before selection

Clear system requirements:

Determine the cooling capacity requirements of the central air conditioning system, which usually depends on the cooling capacity of the air conditioning host and the setting of the air conditioning inlet and outlet water temperature difference.

Understand the flow requirements of the system, including 1.1~1.2 times the rated flow of the chiller (determined according to the single or multiple units in parallel).

Determine the head requirements:

The choice of head depends on the resistance of the water system pipeline, including equipment resistance, along-the-way resistance and local resistance.

Hydraulic calculations are required to estimate the total resistance of the system pipeline and consider a certain safety factor (such as 10%).

2. Selection considerations

Water pump type:

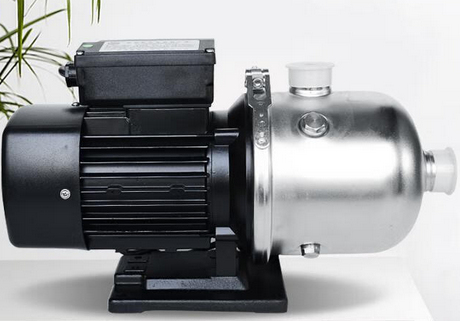

Central air conditioning circulating water pumps generally use centrifugal water pumps because of their simple structure, large flow, and moderate head.

According to actual needs, horizontal or vertical centrifugal pumps can be selected. Vertical pumps occupy a small area, but the motor is heavier at large flow rates; horizontal pumps are easy to maintain, but occupy a large area.

Performance parameters:

Flow rate (Q): Determined according to system requirements, usually 1.1~1.2 times the rated flow rate of the chiller.

Head (H): Determined according to the results of hydraulic calculations, and considering the safety factor.

Efficiency (η): Efficient pumps can reduce operating costs and improve the overall efficiency of the system.

Shaft power (NZ): Calculated based on flow rate, head and efficiency, used to select motor power.

Motor configuration:

The rated power of the motor should be slightly greater than the shaft power of the pump to ensure that the pump can operate normally and consider a certain overload capacity.

The motor type is generally a three-phase asynchronous motor, which is selected according to the rated speed of the pump (such as 1450r/min or 2900r/min).

3. Selection steps

Clearly define the cooling capacity and head requirements:

According to the cooling capacity of the air-conditioning system and the inlet and outlet water temperature difference, calculate the cooling capacity requirements.

Perform hydraulic calculations to estimate the total resistance of the system pipeline and determine the head requirements.

Select the appropriate pump type:

According to the system requirements and pump characteristics, select a centrifugal pump and determine the horizontal or vertical form.

Determine the pump performance parameters:

According to the system flow and head requirements, select the appropriate pump model and specifications.

Consult the pump sample or technical information to obtain specific performance parameters (such as flow, head, efficiency, etc.).

Select the motor configuration:

According to the pump shaft power and motor efficiency, calculate the motor configuration power.

Select the appropriate motor model and rated power to ensure that the motor can drive the pump to operate normally.

Perform performance testing and verification:

Before actual installation, perform performance testing and verification on the selected pump to ensure that its performance parameters meet the system requirements.

Make necessary adjustments and optimizations based on the test results to ensure that the pump can smoothly cooperate with the entire central air-conditioning system.