Selection of Gear Pump Safety Valve

The selection of gear pump safety valve mainly depends on the specific working conditions and requirements. The following are the selection points considered from multiple aspects:

1. Use occasions

Large flow, high pressure occasions: In occasions where large flow or high pressure needs to be handled, it is usually recommended to use a safety valve. The safety valve can automatically open when the pressure reaches a certain range, release excess pressure, and thus protect the equipment and system from damage.

Small flow, high precision occasions: For occasions with small flow and high pressure accuracy requirements, you may need to consider using a pressure regulating valve. But please note that this does not mean that safety valves cannot be used in these occasions, but need to be weighed according to specific needs.

2. Characteristics of safety valves

Automatic opening and closing: The safety valve has the function of automatically opening and releasing pressure when the pressure exceeds the set value, and automatically closing when the pressure drops to a safe range. This feature makes the safety valve very effective in protecting equipment from damage caused by excessive pressure.

Set pressure: The set pressure of the safety valve should be determined according to the rated working pressure of the gear pump. Generally speaking, the opening pressure of the safety valve should be slightly higher than the rated working pressure of the gear pump to ensure that it will not malfunction under normal working conditions. At the same time, the maximum working pressure and fluctuation range of the system should also be considered to ensure that the safety valve can be opened in time when necessary.

3. Selection considerations

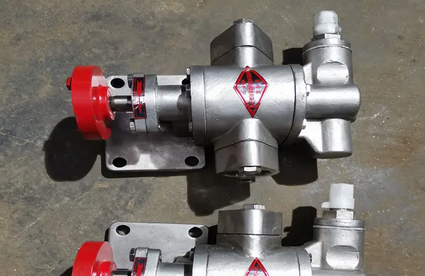

Structure and materials: The structure of the safety valve should be simple and reliable, and the material should have good corrosion resistance and high temperature resistance. When selecting, well-known brands and certified products should be given priority to ensure their quality and performance.

Maintenance and care: The safety valve needs to be regularly maintained and serviced during use to ensure its normal operation and extend its service life. This includes checking the sealing performance of the safety valve, cleaning the deposits, and replacing damaged parts.

Matching use: In some cases, it may be necessary to use the safety valve with other valves or devices to achieve better protection. For example, in situations where precise pressure control is required, the safety valve can be used in combination with a pressure regulating valve.

4. Specific selection suggestions

According to flow and pressure requirements: First, clarify the flow and pressure requirements of the gear oil pump, as well as the maximum working pressure and fluctuation range of the system. Then select the appropriate safety valve model and specification based on this information.

Consider the characteristics of the medium: If the medium has characteristics such as corrosiveness or high temperature, it is necessary to select a safety valve material that can withstand these characteristics.

Refer to the manufacturer's recommendations: During the selection process, you can consult the gear pump and safety valve manufacturers or professional suppliers to obtain more specific suggestions and solutions.