Selection of marine centrifugal pumps

The selection of marine centrifugal pumps is a complex and meticulous process that requires consideration of multiple factors to ensure that the selected pump can meet the specific needs of the ship. Here are some key selection steps and considerations:

1. Selection steps

Clear requirements:

Determine the type of pump required (such as vertical, horizontal, self-priming, etc.).

Determine the flow and head requirements of the pump, which are usually based on factors such as the ship's displacement, speed, and the nature of the pumped medium.

Collect information:

Understand the overall design of the ship, the layout of the pump room, the piping system, and the characteristics of the pumped medium (such as temperature, pressure, corrosiveness, viscosity, etc.).

Performance parameter matching:

Select the appropriate pump model according to the needs to ensure that the performance parameters such as the pump flow, head, speed, and motor power meet the requirements.

Material selection:

Select appropriate materials such as pump body, impeller, seal, etc. according to the nature of the pumped medium to ensure the corrosion resistance and wear resistance of the pump.

Comprehensive consideration:

Evaluate the reliability, maintainability, economy and other factors of the pump and select a pump model with high cost performance.

2. Considerations

Flow and head:

Flow refers to the amount of liquid delivered by the pump per unit time, and head refers to the height to which the pump can deliver liquid. These two parameters are the most critical indicators when selecting.

Medium characteristics:

Different media have different requirements for pump materials and sealing methods. For example, seawater pumps need to choose corrosion-resistant materials and sealing methods.

Temperature and pressure:

The working temperature and pressure of the medium will affect the performance and life of the pump. Therefore, it is necessary to clarify the working temperature and pressure range of the medium when selecting.

Motor power and speed:

The motor power and speed determine the output power and efficiency of the pump. Choosing the right motor power and speed can increase the service life and efficiency of the pump and reduce energy consumption.

Structural type:

Marine centrifugal pumps have various structural types, including vertical, horizontal, self-priming, etc. Choosing the right structural type can save space and facilitate installation and maintenance.

Sealing and wear resistance:

Sealing and wear resistance are important factors affecting pump performance and life. It is necessary to select pump types and materials with good sealing and wear resistance.

3. Specific selection suggestions

Vertical centrifugal pump:

Suitable for occasions with limited space, such as the pump room of a ship. The vertical centrifugal pump has a compact structure, small footprint, and is easy to install and maintain.

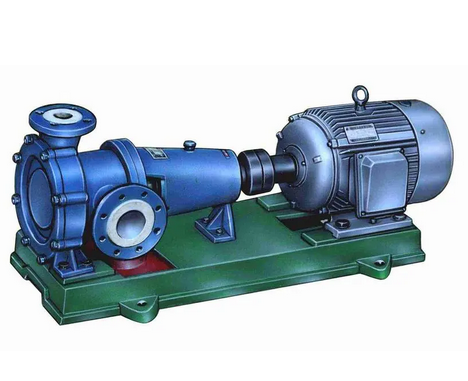

Horizontal centrifugal pump:

Suitable for occasions requiring a large flow rate. The horizontal centrifugal pump has a stable structure, smooth operation, and is suitable for long-term continuous work.

Self-priming centrifugal pump:

Suitable for occasions requiring self-priming ability, such as the bilge pump of a ship. The self-priming centrifugal pump can automatically suck in the medium without water diversion, which is convenient and fast.

Special material pump:

For highly corrosive media, such as seawater, it is necessary to select a pump body and impeller made of stainless steel or alloy. These materials have good corrosion resistance and can extend the service life of the pump.

Efficient and energy-saving pump:

With the improvement of environmental awareness, it is increasingly important to choose an efficient and energy-saving pump type. These pump types can reduce energy consumption and emissions during operation, which meets the requirements of sustainable development.