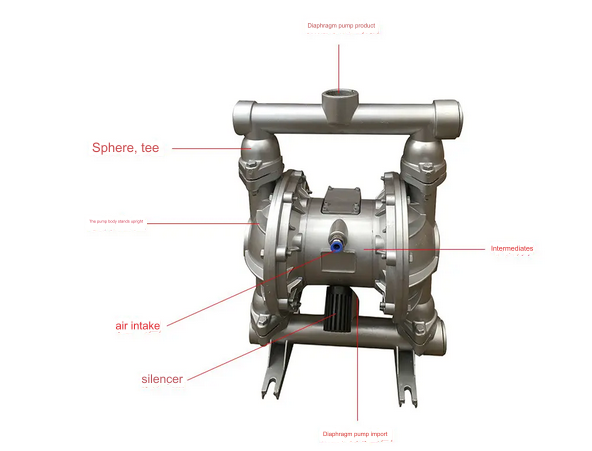

Special structure description of pneumatic dust diaphragm pump

The special structure of the pneumatic dust diaphragm pump is mainly reflected in its design details and component composition, which work together to affect the performance and efficiency of the pump. The following is a detailed description of the special structure of the pneumatic dust diaphragm pump:

1. Overall structure

The pneumatic dust diaphragm pump is mainly composed of pneumatic motor, pneumatic control valve, diaphragm assembly, inlet and outlet connecting pipes and other parts. These components work together to complete the liquid (or dust) conveying task of the pump body.

2. Core components and special structures

Pneumatic motor

Structure: The pneumatic motor is the core component of the pneumatic dust diaphragm pump and provides the driving force for the movement of the pump body. It is mainly composed of rotor assembly, rotor rear cover, rotor rear lock plate, front cover, rotor front lock plate and other components.

Features: simple structure, high reliability, and can adapt to various harsh working environments. When compressed air enters the pneumatic motor, it will drive the rotor to rotate, thereby driving the pump body to work.

Pneumatic control valve

Function: In the pneumatic dust diaphragm pump, the pneumatic control valve plays the role of a controller that determines the flow and working state of the pump.

Special structure: usually includes springs, pistons, regulating valves, switches and other components. Its reversibility enables it to control pressure and the corresponding flow rate to ensure that the pump body operates in the best condition. By adjusting the switch of the air control valve, the flow rate and pressure of the pump body can be accurately controlled to meet the needs of different working conditions.

Diaphragm assembly

Composition: The diaphragm assembly is an important component of the pneumatic dust diaphragm pump. It consists of two rubber or polytetrafluoroethylene composite diaphragms and is connected to the pump body through four screws.

Special design: The two diaphragms completely isolate the two fluid chambers of the pump body to prevent the media inside and outside the pump body from mixing with each other. At the same time, the diaphragm assembly can also protect the pneumatic motor from corrosion and wear. In addition, the corrosion resistance and wear resistance of the diaphragm assembly also enable it to adapt to the delivery tasks of various corrosive liquids (or dust).

Special structure: In some designs, the cross-sectional shape of the diaphragm mesh is changed to a cone. This design can make the diaphragm more evenly subjected to air pressure, thereby extending the service life of the diaphragm.

Inlet and outlet connection pipes

Function: The inlet and outlet connection pipes are another important part of the pneumatic dust diaphragm pump. They connect the inlet and outlet of the pump body and are the channels for liquid (or dust) transportation.

Special design: Usually made of stainless steel, it can withstand high pressure environment and strong corrosive media. At the same time, its design also takes into account the flow and pressure requirements of the pump body to ensure that the liquid (or dust) can enter and exit the pump body smoothly.