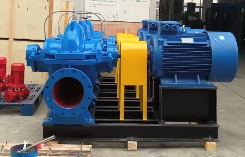

Structural features of double suction pump

As an important form of centrifugal pump, double-suction pump has been widely used and recognized in the engineering field. Its structural characteristics are mainly reflected in the following aspects:

Double impeller design: The impeller of the double-suction pump is composed of two back-to-back impellers. This design allows the flow rate to be doubled under the same impeller outer diameter, which is equivalent to two single-suction impellers of the same diameter working at the same time, greatly improving the working efficiency of the pump.

Horizontal center opening of the pump casing: The pump casing adopts a horizontal center opening design. This structure is not only convenient for inspection and maintenance, but also reduces the difficulty and time cost of maintenance. At the same time, the inlet and outlet of the double-suction pump are in the same direction and perpendicular to the pump shaft. This layout is conducive to the arrangement and installation of the pump and the inlet and outlet pipes, and improves the overall flexibility and convenience of the system.

Smooth operation: The impeller structure of the double-suction pump is symmetrical. This design effectively eliminates the axial force, making the pump more stable during operation. In addition, the optimized double-suction impeller and the blade shape with excellent hydraulic performance make the pump low noise and vibration during operation, further improving the stability and reliability of the pump.

Compact structure and easy installation: The overall structure of the double suction pump is compact, beautiful in appearance, stable and easy to install. Whether it is a separate or horizontal installation, it can be flexibly selected according to the on-site conditions to meet the needs of different occasions.

Seals and bearings: In terms of sealing, double suction pumps usually use high-quality mechanical seals or packing seals, such as BURGMANN mechanical seals, which can ensure long-term operation without leakage. At the same time, the selected SKF and NSK bearings also ensure the smooth operation of the pump, low noise and long service life.