Technical requirements for centrifugal pump foundation holes

The technical requirements for the reserved holes of the centrifugal pump foundation involve multiple aspects to ensure the stable installation and safe operation of the pump. The following are the key technical requirements summarized based on the reference articles:

1. Basic dimensions of anchor bolts and reserved holes

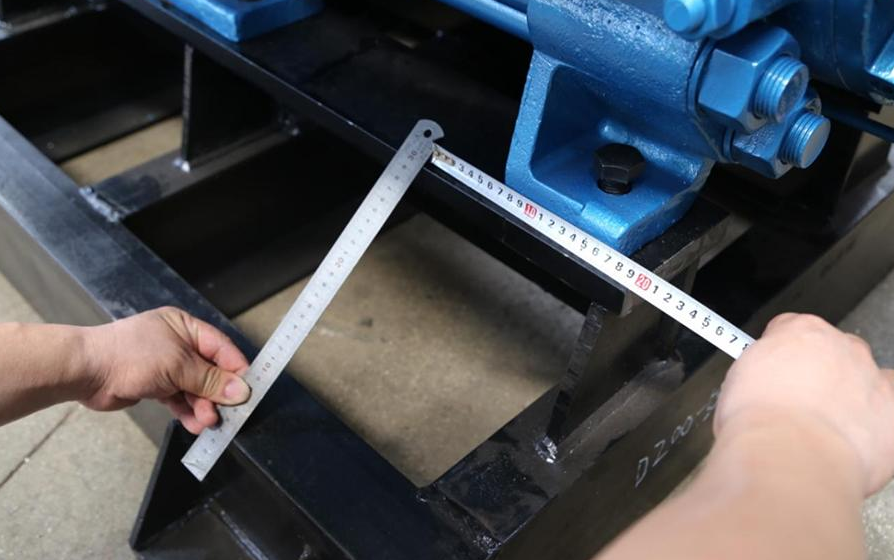

Reserved hole size: The size of the reserved hole should be determined according to the diameter and length of the anchor bolt. Generally speaking, the depth of the hole is about 1.5 times the length of the anchor bolt, and the width and length of the hole are determined according to the diameter and fixing needs of the anchor bolt. For example, the hole size of the anchor bolt above M36 is usually 200x200mm, the bolt hole size of M24 to M27 is 150x150mm, and the bolt hole size below M24 is 100x100mm.

The buried depth of the anchor bolt: The buried foundation length of the anchor bolt should not be less than 20 times the bolt diameter (l≥20d), and the bolt fork tail length is 4d bolt. The depth of the reserved screw hole should be 3-5cm greater than the total buried length of the bolt.

2. Grouting and fixing requirements

Grouting materials: The grouting materials for the reserved holes of the multi-stage centrifugal pump foundation and the secondary grouting layer are generally fine crushed stone concrete, and its grade should be one level higher than the grade of the foundation concrete.

Grouting time: The secondary grouting layer can be grouted only when the concrete reaches the design strength of more than 75%. The height of the grouting layer is generally 30-70 mm.

Grouting operation: When compacting the concrete in the reserved holes of the centrifugal pump foundation, the anchor bolts of various centrifugal pumps must not be skewed or the pump and pump group equipment must not be displaced. After grouting, proper maintenance should be carried out to ensure the quality of the grouting layer.

3. Installation and adjustment of anchor bolts

Preparation before installation: The anchor bolts placed in the reserved holes should be straight and without tilt, the bare rod part should be free of oil or oxide scale, and the threaded part should be greased to prevent rust.

Installation process: Insert the anchor bolts into the screw holes of the water pump and motor foundation, hang them on the foundation seat, and place U-shaped pads under the water pump and motor foot plates. Initially calibrate the parallelism, concentricity and horizontality of the water pump and motor, and adjust the gap between the water pump and the motor coupling.

Tightening torque: Tightening the anchor bolts should be carried out when the concrete in the reserved hole reaches more than 75% of the design strength. The tightening torque and axial tension parameter values must meet the design requirements.

IV. Consideration of foundation and environment

Foundation requirements: The foundation should be solid and firm, and in addition to being able to withstand the static load of the unit, it can also withstand mechanical vibration loads. The top surface of the foundation should not be less than 200mm above the ground, and its burial depth should not be less than 0.8m, and not less than the freezing depth.

Environmental adaptability: When the ambient temperature is lower than 5°C, insulation or anti-freeze measures should be taken during the maintenance of the secondary grouting layer.

V. Other precautions

Reserved hole position: The distance from the edge of the reserved hole to the edge of the foundation shall not be less than 100mm to ensure the stability of the foundation and the firmness of the anchor bolts.

Maintenance inspection: Regularly check the anchor bolts and reserved holes to ensure that they are not loose or rusted, and perform timely maintenance to ensure stable operation of the pump.