The Energy Efficiency and Advantages of Oil Pumps vs. Water Pumps: A Comparative Analysis

In the realm of fluid transfer, oil pumps and water pumps play pivotal roles across various industries. While both serve the fundamental purpose of moving liquids, their operational principles, energy efficiency, and advantages differ significantly due to the distinct properties of the fluids they handle. This essay delves into the comparative analysis of oil pumps and water pumps, focusing on their energy efficiency and unique advantages.

Energy Efficiency: A Tale of Two Fluids

The energy efficiency of a pump is intrinsically linked to the viscosity and density of the fluid it transports. Oil, being a more viscous and dense fluid compared to water, requires more energy to pump. This fundamental difference in fluid properties leads to distinct energy consumption patterns between oil pumps and water pumps.

Oil Pumps: Overcoming Viscosity

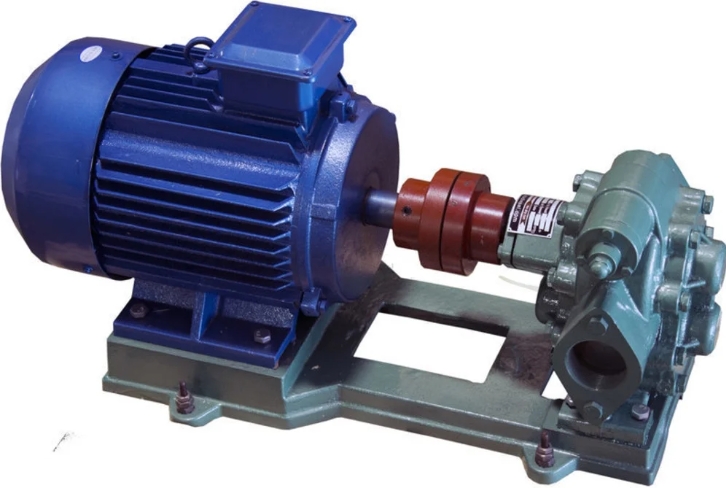

Oil pumps are designed to handle the high viscosity of oil, which creates significant internal friction within the pump. This friction necessitates more powerful motors and robust pump designs to overcome the resistance and maintain flow rates. Consequently, oil pumps generally consume more energy than water pumps. However, advancements in pump technology, such as the use of variable frequency drives (VFDs) and optimized impeller designs, have improved the energy efficiency of oil pumps. These innovations allow for better control over pump speed and flow rates, reducing energy consumption during periods of low demand.

Water Pumps: The Efficiency of Low Viscosity

Water pumps, on the other hand, benefit from the low viscosity and density of water. The minimal internal friction within the pump allows for smoother operation and lower energy consumption. Water pumps can achieve high flow rates with relatively low power input, making them inherently more energy-efficient than oil pumps. Additionally, the widespread use of centrifugal pumps in water applications further enhances efficiency, as these pumps are well-suited to handle the low viscosity of water with minimal energy loss.

Advantages: Tailored to Fluid Properties

Beyond energy efficiency, oil pumps and water pumps offer distinct advantages tailored to the properties of the fluids they handle.

Oil Pumps: Precision and Durability

Oil pumps excel in applications requiring precise control over flow rates and pressure. The high viscosity of oil necessitates robust pump designs that can withstand the stresses of pumping thick fluids. This durability makes oil pumps ideal for industrial applications, such as lubrication systems, hydraulic systems, and fuel transfer. Moreover, oil pumps are often equipped with advanced control systems that allow for precise regulation of flow and pressure, ensuring optimal performance in critical applications.

Water Pumps: Versatility and Cost-Effectiveness

Water pumps are renowned for their versatility and cost-effectiveness. The low viscosity of water allows for a wide range of pump designs, from simple centrifugal pumps to more complex multi-stage pumps. This versatility enables water pumps to be used in diverse applications, including irrigation, water supply, and wastewater treatment. Additionally, the relatively low energy consumption of water pumps translates to lower operational costs, making them an economical choice for large-scale water management systems.

Conclusion: A Balanced Perspective

In conclusion, the energy efficiency and advantages of oil pumps and water pumps are deeply rooted in the properties of the fluids they handle. Oil pumps, while generally less energy-efficient due to the high viscosity of oil, offer precision and durability in demanding industrial applications. Water pumps, benefiting from the low viscosity of water, provide versatility and cost-effectiveness in a wide range of water management systems. Understanding these differences is crucial for selecting the appropriate pump for a given application, ensuring optimal performance and energy efficiency. As technology continues to advance, both oil pumps and water pumps are likely to see further improvements in energy efficiency, driven by innovations in pump design and control systems.