Troubleshooting: Why an Air-Operated Diaphragm Pump Fails to Pump Water

Troubleshooting: Why an Air-Operated Diaphragm Pump Fails to Pump Water

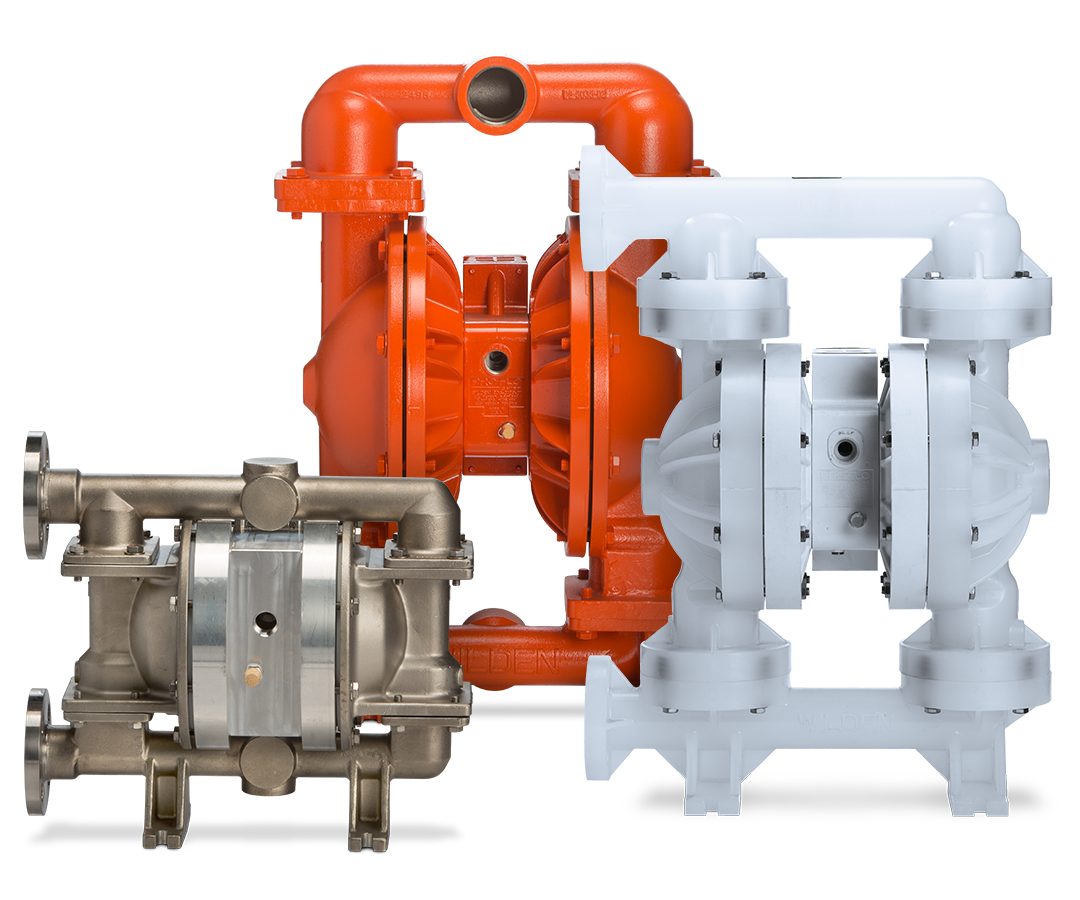

Air-operated diaphragm pumps (AODD pumps) are widely used in various industries due to their ability to handle a range of fluids and operate in challenging conditions. However, one common issue is when the pump fails to draw or pump water. This article explores the potential causes of this problem and provides actionable solutions to restore functionality.

1. Insufficient Air Supply

One of the primary reasons an AODD pump may fail to pump water is an inadequate or inconsistent air supply. Without sufficient air pressure or volume, the pump cannot operate effectively.

Symptoms: The pump operates slowly or erratically.

Solutions:

Check the air pressure and ensure it meets the manufacturer’s specifications.

Inspect the air supply line for leaks or obstructions.

Ensure the air compressor is functioning correctly and providing a steady supply of air.

2. Clogged or Blocked Inlet/Outlet

Blockages in the inlet or outlet of the pump can prevent water from flowing through the system.

Symptoms: The pump cycles, but no fluid is discharged.

Solutions:

Inspect the inlet and outlet for debris or sediment buildup.

Clean or replace clogged hoses, filters, or strainers.

Ensure the suction line is submerged and free of air leaks.

3. Air Leakage in the System

Air leaks within the pump or the connected system can disrupt its operation and prevent it from creating the necessary suction.

Symptoms: The pump cycles but fails to draw fluid.

Solutions:

Check all fittings, seals, and gaskets for signs of wear or damage.

Tighten loose connections and replace damaged components.

Inspect the diaphragm for tears or punctures that could cause air leaks.

4. Damaged or Worn Diaphragm

The diaphragm is a critical component of the pump. If it becomes worn or damaged, the pump may lose its ability to create suction.

Symptoms: The pump cycles without moving fluid, or fluid leaks from the diaphragm chamber.

Solutions:

Inspect the diaphragm for cracks, tears, or excessive wear.

Replace damaged diaphragms with new ones that meet the pump’s specifications.

5. Improper Installation or Setup

Incorrect installation or setup can prevent the pump from operating efficiently.

Symptoms: The pump does not cycle or cycles erratically.

Solutions:

Verify that the pump is installed according to the manufacturer’s guidelines.

Check that the suction and discharge lines are correctly sized and positioned.

Ensure there are no sharp bends or kinks in the hoses that could restrict flow.

6. Air Valve Malfunction

The air valve directs compressed air to the pump’s diaphragms, and any malfunction in this component can disrupt the pump’s operation.

Symptoms: The pump fails to cycle or operates inconsistently.

Solutions:

Inspect the air valve for blockages or wear.

Clean or replace the valve as necessary.

Lubricate moving parts to ensure smooth operation.

7. Fluid Viscosity or Particulates

AODD pumps are designed to handle a variety of fluids, but extremely viscous liquids or those with large particulates can pose challenges.

Symptoms: The pump struggles to draw fluid or operates very slowly.

Solutions:

Ensure the pump is rated for the fluid’s viscosity and particulate size.

Use pre-filters or strainers to remove large particles before they enter the pump.

Adjust the air pressure to provide additional force for handling viscous fluids.

8. Worn Check Valves

Check valves prevent backflow and ensure that fluid moves through the pump in the correct direction. Worn or damaged check valves can impair performance.

Symptoms: Fluid flows back into the suction line or fails to discharge.

Solutions:

Inspect the check valves for wear, cracks, or debris.

Clean or replace faulty check valves as needed.

9. Suction Lift Issues

If the pump is required to lift fluid from a significant depth, it may struggle if the setup is not optimized.

Symptoms: The pump cycles but fails to draw fluid from the source.

Solutions:

Ensure the suction lift is within the pump’s specified range.

Prime the pump to remove air from the suction line.

Reduce the height of the suction lift if possible.

10. Excessive Wear and Tear

Over time, components of the pump may wear out due to prolonged use or exposure to harsh conditions.

Symptoms: The pump’s performance gradually declines.

Solutions:

Perform regular maintenance and replace worn parts as needed.

Follow a maintenance schedule recommended by the manufacturer.

Use compatible materials for the fluid being handled to minimize wear.

Conclusion

An air-operated diaphragm pump failing to pump water can stem from various causes, ranging from air supply issues to component wear. By systematically troubleshooting and addressing these potential problems, you can restore the pump’s performance and minimize downtime. Regular maintenance and adherence to manufacturer guidelines are essential for ensuring the long-term reliability of AODD pumps.