Types of self-priming pump impellers

There are three main types of self-priming pump impellers, each with different structures and characteristics, suitable for different working occasions and media. The following is a detailed introduction to the types of self-priming pump impellers:

1. Closed impeller

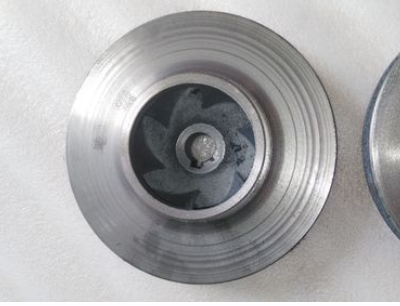

Structural features: The closed impeller has front and rear covers, and the blades and the disc are closed. The design of this impeller makes it have higher working efficiency and stronger wear resistance and corrosion resistance.

Blade form: The closed impeller usually has 2 to 12 backward curved blades, and the blades are relatively short, which is conducive to reducing friction loss and hydraulic loss, and improving the efficiency and energy saving effect of the pump.

Application scenario: The closed impeller is suitable for treating liquids that are easy to form solids and corrosive, such as sewage. Due to its high efficiency and durability, closed impellers are widely used in sewage treatment, chemical industry and other fields.

2. Open impeller

Structural features: The open impeller refers to an impeller whose connection between the blade and the disc is not closed. The structure of this impeller is relatively simple and easy to process and repair.

Blade form: The open impeller has fewer blades, generally 2 to 5, and the blades are relatively slender. This design gives the open impeller a certain advantage when pumping liquids or sewage containing particles.

Application scenario: The open impeller is suitable for handling liquids such as fibers and large particles. However, because its blades are slender and easily damaged, special attention should be paid to protection when using it.

3. Semi-open impeller

Structural features: The connection between the blades and the wheel disc of the semi-open impeller is partially closed, which is between the open and closed impellers. This impeller combines the advantages of open and closed impellers and has high durability and adaptability.

Blade form: The number of blades of the semi-open impeller is also relatively small, but its structure is more solid and can be used at a higher speed.

Application scenario: The semi-open impeller is suitable for handling medium-sized solids and fibers. Its simple structure, durability and easy maintenance make it work well in a variety of working occasions.

Material selection

The material of the self-priming pump impeller needs to have sufficient mechanical strength, corrosion resistance and wear resistance. According to the requirements of the conveying medium, impellers of different materials can be selected. Currently commonly used materials include cast iron, cast steel, stainless steel, etc. Among them, stainless steel impellers are widely used due to their excellent corrosion resistance and wear resistance.