Vibration Analysis and Balancing Methods for Pumps

The vibration analysis and balancing method of the pump is the key link to ensure the stable operation of the pump and extend its service life. The following is a clear summary and analysis of this:

1. Vibration analysis

Causes of vibration:

Motor factors: loose motor structure, bearing failure, rotor imbalance, etc.

Foundation and bracket: loose foundation, insufficient bracket rigidity, loose anchor bolts, etc.

Impeller and rotor: eccentric impeller mass, improper design of blade number and angle, rotor bending, etc.

Pipeline and installation: insufficient rigidity of pipeline bracket, large internal stress of inlet and outlet pipelines, poor pipeline, etc.

Other factors: improper pump selection, non-design operating conditions, poor bearing lubrication, etc.

Vibration impact:

Reduce pump performance and efficiency, increase energy consumption.

Accelerate component wear and shorten the service life of the pump.

Cause noise and vibration, affect the environment and user comfort.

2. Balancing method

Mechanical balance:

Impeller balance: Ensure uniform distribution of impeller mass and reduce vibration by adding or removing weights.

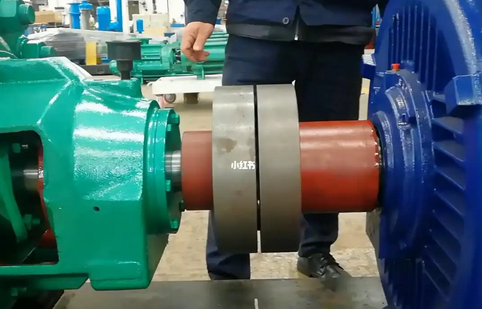

Rotor balance: Dynamically balance the rotor to ensure its stability at high speed rotation.

Structural reinforcement:

Strengthen the rigidity of the foundation and bracket to ensure the stability of the pump body.

Regularly check and tighten the anchor bolts to prevent loosening.

Lubrication and maintenance:

Ensure that the bearings are well lubricated and replace worn bearings in time.

Regularly check the motor and pump components to find and deal with potential problems in time.

Pipeline optimization:

Strengthen the rigidity of the pipeline bracket to reduce the pressure of the pipeline on the pump body.

Ensure that the inlet and outlet pipelines are installed reasonably to reduce internal stress.

Operation adjustment:

Ensure that the pump operates under rated conditions to avoid overload or non-design conditions.

Regularly check and adjust the pump's operating parameters, such as speed, flow, etc.