What is the difference between a centrifugal pump and an axial flow pump?

There are significant differences between centrifugal pumps and axial flow pumps in many aspects. The following is a detailed explanation of the differences between the two:

1. Working principle:

Centrifugal pump: The centrifugal force generated by the high-speed rotation of the impeller is used to throw out the liquid, and then a low-pressure area is formed in the center of the impeller. The liquid is sucked in and thrown out again to realize the transportation of the liquid.

Axial flow pump: It works by using the thrust (lift) generated by the rotation of the impeller on the water body. It is a large flow and low head water pump. The fluid flow direction is parallel to the impeller rotation direction.

2. The direction of liquid flow (water) outflow after passing through the impeller:

Centrifugal pump: radial flow under the action of centrifugal force.

Axial flow pump: Maintain axial flow (parallel to the center of rotation of the impeller).

3. Specific rotation number:

Centrifugal pump: specific speed is usually below 300.

Axial flow pump: specific rotation number is greater than 500.

4. Performance curve and startup method:

Centrifugal pump: In use, it is usually started by closing the valve. At this time, the power is relatively small and the motor is not easy to be burned.

Axial flow pump: It is not suitable to start with the valve closed, but should be started with the valve opened. At this time, the power is relatively small and the motor is not easy to be burned.

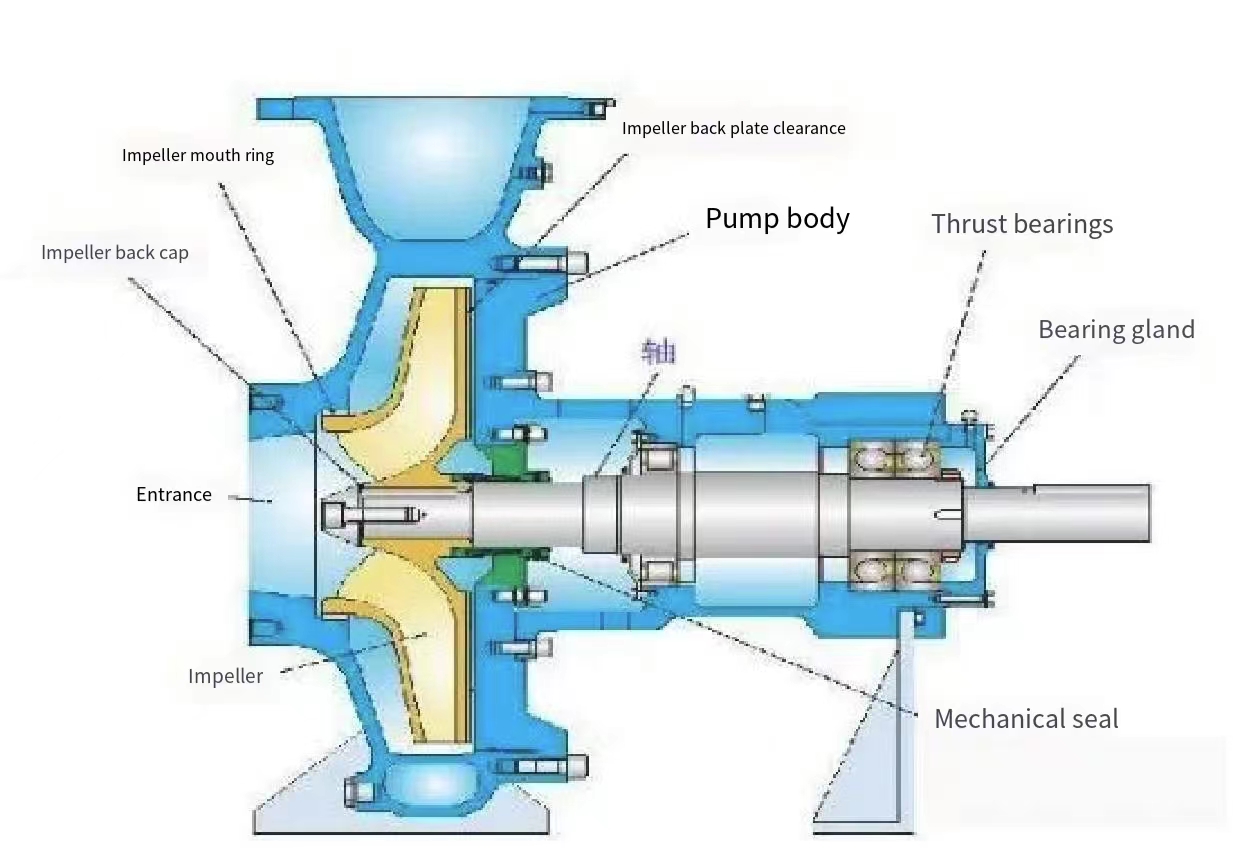

5. Structure:

Centrifugal pump: generally has a volute, and its basic structure consists of six parts: impeller, pump body, pump shaft, bearings, sealing rings and stuffing box.

Axial flow pump: Although its detailed structure is not explicitly mentioned in the article, its design usually focuses more on generating axial thrust so that the fluid can flow along the axial direction.

6. Applicable scenarios:

Centrifugal pumps: widely used in many fields such as industry, agriculture, water conservancy, urban water supply and drainage, such as petrochemical, pharmaceutical, food and other industries, as well as agricultural irrigation, municipal water supply, etc.

Axial flow pumps: Mainly suitable for low-lift, large-flow applications, such as irrigation, drainage, dock drainage, water level adjustment in canal locks, or used as large circulating water pumps in power plants.

7. Other features:

The axial flow pump can be equipped with a control mode electronic control cabinet with one control, two to one control four, which can automatically shut down the pump when a fault occurs, automatically start the backup pump, and retain fault signals (self-diagnosis) to ensure high reliability of operation. At the same time, the pump is submerged in the water, the cooling conditions are good, and the pump operation is well balanced.