Which pump should I use to draw up sulfuric acid?

When selecting a pump to drawing up sulfuric acid, it is crucial to choose one that can withstand the acid's strong corrosivity and oxidation. Here are some pump models suitable for this task, along with their characteristics:

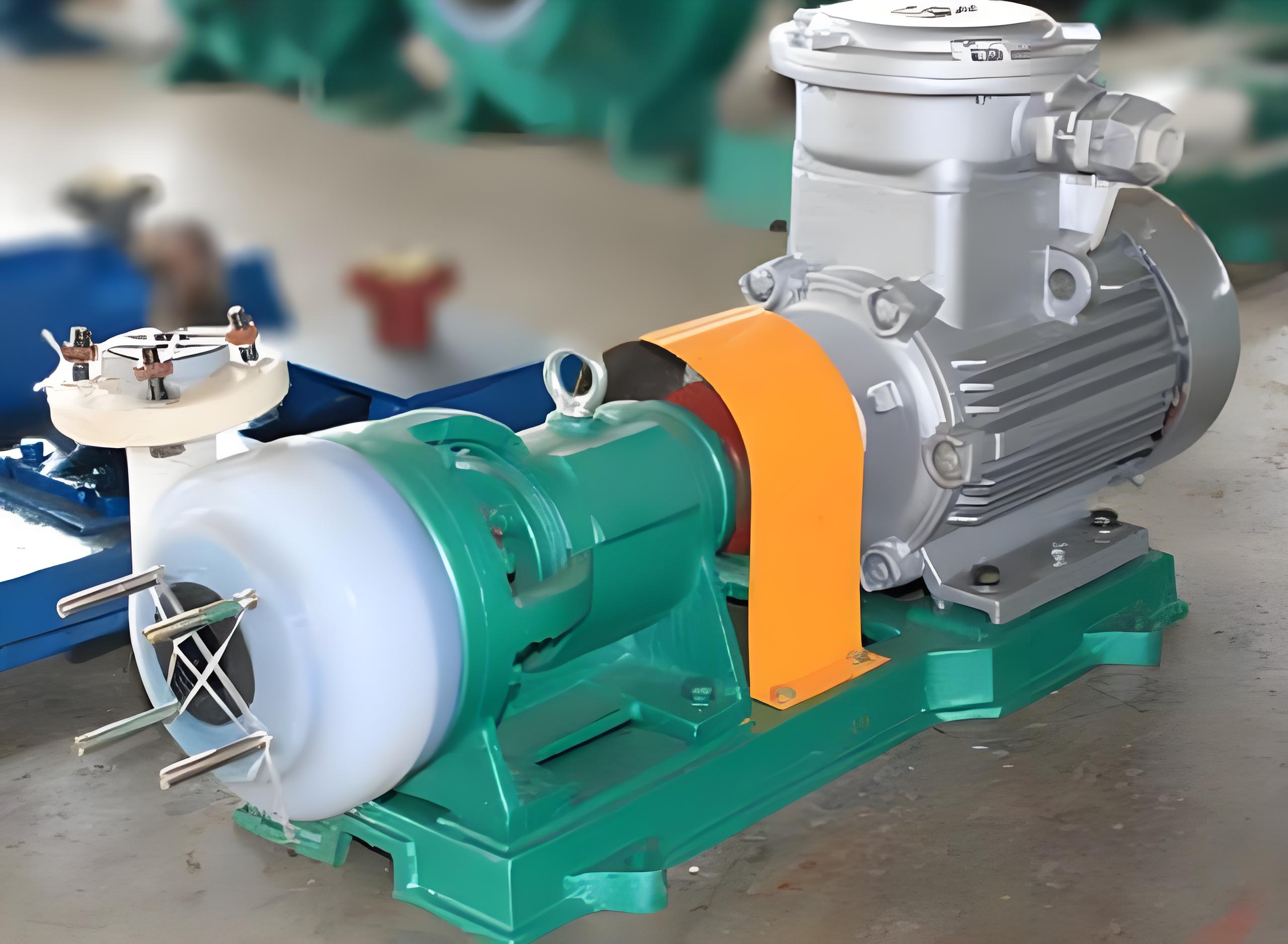

1. Fluorocarbon Centrifugal Pumps

Fluorocarbon centrifugal pumps, such as those made of polyvinyl fluoride (PVDF) or tetrafluoroethylene (PTFE), are ideal for handling sulfuric acid. These pumps have excellent corrosion resistance and high-temperature capabilities. They are suitable for handling various corrosive substances, including strong acids, alkalis, and organic solvents. They feature a balanced design, smooth operation, and tight seals, minimizing leaks and ensuring safety.

2. Ceramic Pumps

Ceramic pumps, often using materials like alumina or zirconia, excel in resisting corrosive conditions. Constructed from high-performance ceramic materials, they can operate reliably under extreme temperatures and pressures. They are particularly advantageous when pumping concentrated sulfuric acid due to their durability and low wear rate.

3. Magnetic Drive Pumps

Magnetic drive pumps (MDP) are an excellent choice for corrosive environments, especially for hazardous, flammable, or toxic fluids like sulfuric acid. MDPs employ a magnetic coupling to transmit power from the motor to the impeller, eliminating mechanical seals and reducing leaks. They offer smooth operation, low noise, and easy maintenance.

4. Alloy Corrosion-Resistant Pumps

For lower concentration or mild temperature applications, alloy corrosion-resistant pumps made of stainless steel or specialty alloys may suffice. These pumps can withstand some degree of sulfuric acid exposure, but their suitability decreases in high-temperature, high-pressure, or highly concentrated sulfuric acid environments.

In summary, when selecting a pump for sulfuric acid, consider factors such as corrosion resistance, material compatibility, operating conditions, and safety features. Choose a pump designed specifically for the acidic environment to ensure optimal performance and minimal damage to equipment.