Working Principle of Gear Pump

The working principle of the gear pump is mainly based on the rotation and mutual meshing of gears to transfer liquid. The following is a detailed explanation of the working principle of the gear pump:

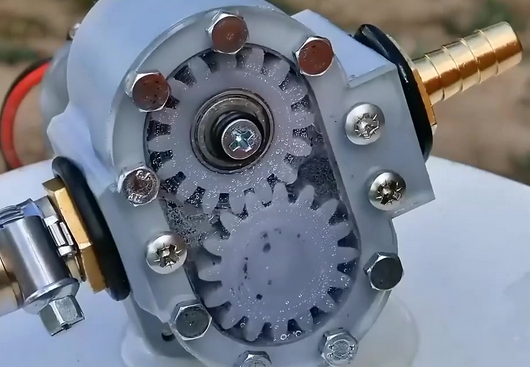

1. Basic structure

The gear pump is mainly composed of two gears (one driving gear and one driven gear), a pump body, front and rear covers and other components. The two gears are nested with each other and are usually located in a sealed pump housing. The pump body and the front and rear covers together form two closed spaces for the suction and discharge of liquid.

2. Working process

Oil suction process:

When the driving gear starts to rotate under the drive of the motor or other power source, the gear teeth gradually disengage, causing the space volume on the disengaged side of the gear to gradually increase.

This enlarged space forms a low-pressure area, which produces a vacuum effect, thereby sucking liquid from the oil inlet (or suction chamber) into the pump.

After the liquid is sucked in, it will flow along the inner wall of the pump housing and fill the space between the two gears.

Oil discharge process:

As the driving gear continues to rotate, the gear teeth enter the meshing state again, causing the space volume on the meshing side of the gear to gradually decrease.

This reduced space will squeeze the liquid, pushing the liquid from the space between the gears to the oil outlet (or discharge chamber).

After being squeezed, the liquid is discharged from the pump through the oil outlet and enters the subsequent hydraulic system or working equipment.

3. Working characteristics

High efficiency: The gear pump has a relatively high working efficiency due to its simple structure and low manufacturing cost.

Stable flow: Since the rotation of the gear is uniform, the flow output by the gear pump is also relatively stable.

Low noise: The structural design of the gear pump makes the noise generated during work relatively small.

Long service life: Due to its simple structure and easy maintenance, the service life of the gear pump is relatively long.

Type

Gear pumps are generally divided into two types: internal gear pumps and external gear pumps. The external gear pump is the most widely used one, with a relatively simple structure, light weight, low cost, reliable operation and a wide range of applications. The internal gear pump has a more complex structure and higher precision requirements, and is suitable for some special occasions.

Gear pumps achieve the suction and discharge of liquids through the rotation and mutual meshing of gears. They have the characteristics of high efficiency, stable flow, low noise and long service life.