Working Principle of Self-priming Centrifugal Pump

Self-priming centrifugal pumps have the advantages of strong self-priming ability, simple structure, and stable operation. They are widely used in industrial and civil fields. The working principle of self-priming centrifugal pumps can be summarized as follows:

Starting stage: Before the pump is started, the pump casing needs to be filled with water or at least kept in a water state. After starting, the motor drives the impeller to rotate at high speed.

Generate negative pressure: As the impeller rotates, the water in the pump chamber is pushed toward the volute, and a vacuum (negative pressure) is formed at the water inlet, causing the water inlet check valve to open.

Inhaling air and liquid: Due to the existence of negative pressure, the air in the suction pipe is sucked into the pump and reaches the outer edge through the impeller channel. At the same time, the liquid also begins to be sucked into the pump chamber.

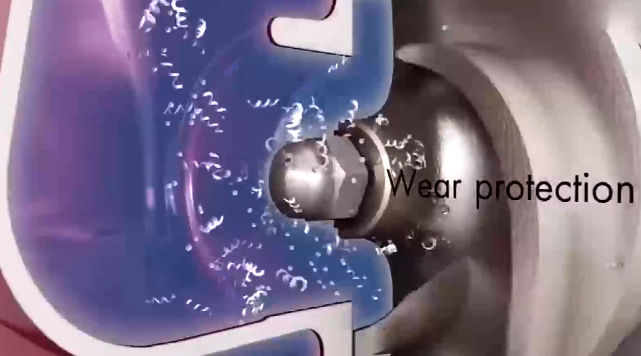

Mixing and separation: The inhaled liquid and air are fully mixed under the action of the impeller, and then the high-speed rotating impeller generates centrifugal force to push the mixture to the outer edge of the pump casing. Under the action of the diffuser, the liquid and air enter the air-water separation chamber. Since the density of water is greater than that of air, the water is pushed downward, while the air moves upward and is discharged through the exhaust port.

Continuous delivery: After the above process, the liquid is gradually lifted into the pump body, and the air in the pump is continuously discharged. As the air continues to decrease, a stable negative pressure is formed in the pump, so that the liquid can be continuously lifted from the pool into the pump body, completing the self-priming process.

Stable operation: When the pump is filled with liquid, the self-priming centrifugal pump enters a stable working state and begins to continuously and efficiently transport liquid.