High-flow sewage pump

High-capacity handling: Efficiently pumps large volumes of sewage and sludge, ideal for industrial/municipal use.

Durability: Built with corrosion-resistant materials for harsh environments and long service life.

Automated & energy-efficient: Self-priming, non-clogging design with low power consumption for cost-effective operation.

I. High-flow sewage pump Overview:

The WQ non-clogging sewage pump is a new generation of pump products developed based on the introduction of advanced foreign technology and combined with the usage characteristics of domestic pumps. It features significant energy-saving effects, anti-entanglement, non-clogging, automatic installation, and automatic control. The WQ type submersible sewage pump adopts a unique structure and new type of mechanical seal, which can effectively convey solid materials and long fibers. Compared with traditional impellers, the impe

ller of this pump adopts a single-channel or double-channel form, similar to a bent pipe with the same cross-sectional size, providing excellent flow performance. Equipped with a reasonable volute, the pump achieves high efficiency. The impeller has undergone static and dynamic balance tests, ensuring vibration-free operation. An automatic coupling device can be optionally purchased, which allows for easy lifting, separation, and combination of the pump using a hoist chain during maintenance. Maintenance personnel do not need to enter the water to disassemble the pump, effectively enhancing operational convenience and safety.

II. High-flow sewage pump Features:

1. It adopts a unique single-blade or double-blade impeller structure, greatly improving the ability to pass solid materials. It can effectively pass fibrous materials up to 5 times the pump's diameter and solid particles with a diameter of about 50% of the pump's diameter.

2. The mechanical seal uses a new type of hard, corrosion-resistant tungsten carbide material, enabling the pump to run safely and continuously for more than 8000 hours.

3. The overall structure is compact, with a small volume and low noise. It offers significant energy-saving effects and is easy to maintain. There is no need to build a pump room. The pump can work submerged in water, greatly reducing the cost of the project.

4. The pump's sealing oil chamber is equipped with a high-precision anti-interference water leakage detection sensor. The stator winding is pre-embedded with a thermosensitive element for automatic protection of the pump motor.

5. An automatic control cabinet can be equipped according to user needs to automatically protect the pump against water leakage, electrical leakage, overload, and overheating, enhancing the product's safety and reliability.

6. The float switch can automatically control the start and stop of the pump according to the required liquid level changes, without the need for a dedicated person to watch over it, making it extremely convenient to use.

7. The WQ series can be equipped with a dual-rail automatic coupling installation system according to user needs, which brings greater convenience to installation and maintenance. People do not need to enter the sewage pit for this purpose.

8. It can be used within the full head range to ensure that the motor will not be overloaded.

9. There are two different installation methods: fixed automatic coupling installation system and mobile free installation system.

III. High-flow sewage pump Applications:

It is suitable for conveying sewage and solid materials in industries such as chemical, petroleum, pharmaceutical, mining, papermaking, cement plants, steel mills, power plants, coal processing, urban sewage treatment plant drainage systems, municipal engineering, and construction sites. It can also be used for pumping clear water and corrosive media.

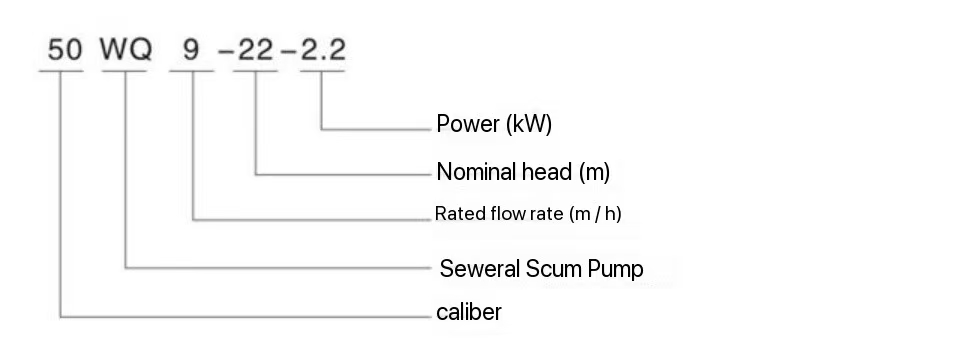

IV. Model Significance:

V. Usage Conditions:

The WQ sewage pump can operate continuously under the following conditions:

1. The medium temperature does not exceed 40℃

2. The pH value of the medium is between 4 and 10

3. The density of the medium is not more than 1.2*10³kg/m³

4. Power supply frequency is 50Hz

5. Submersion depth does not exceed 5 meters

VI. Real photos: