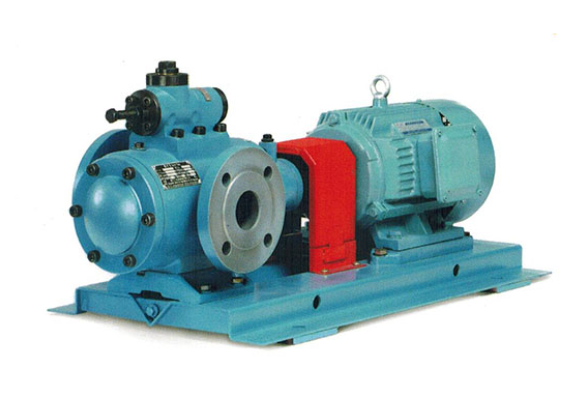

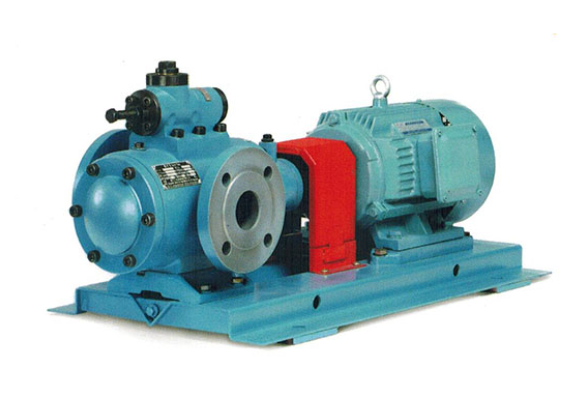

Decoding Screw Pump Pressure and Its Analysis in Practical Scenarios

Decoding Screw Pump Pressure and Its Analysis in Practical Scenarios

Pressure is another vital parameter when it comes to analyzing the working conditions of a screw pump. Understanding the pressure behavior can provide valuable insights into the pump's performance and potential issues.

Take the case of a petrochemical plant that uses a screw pump to transfer a high - pressure liquid - phase hydrocarbon mixture. The pump was designed to operate at a discharge pressure of 800 psi. However, during routine operation, the pressure gauge installed at the pump's discharge port showed a pressure of 1000 psi, which was well above the rated value.

The first thing to check in a high - pressure situation like this is the discharge pipeline. In the petrochemical plant, the maintenance team conducted a detailed inspection of the pipeline. They found that there was a partial blockage in the pipeline due to the formation of wax deposits. These wax deposits were a result of the low - temperature sections in the pipeline, where the hydrocarbon mixture started to solidify and accumulate. The blockage restricted the flow of the hydrocarbon mixture, causing the pressure to build up in the pump. To resolve this issue, the plant had to implement a pipeline - cleaning procedure, including the use of chemical solvents to dissolve the wax deposits.

Another factor that can contribute to abnormal pressure in a screw pump is the viscosity of the fluid being pumped. In the petrochemical industry, the viscosity of hydrocarbon mixtures can change depending on factors such as temperature and composition. If the viscosity of the mixture increased due to a drop in temperature, the pump would need to work harder to push the fluid through the system, resulting in higher pressure. In this case, the plant adjusted the temperature control system to maintain the optimal temperature for the hydrocarbon mixture, which helped to reduce the viscosity and bring the pump's discharge pressure back to the normal range.

In conclusion, analyzing the pressure conditions of a screw pump requires a comprehensive examination of the pipeline conditions and the properties of the pumped fluid. By doing so, industries can ensure the safe and efficient operation of their screw pumps.

Get the latest price? We'll respond as soon as possible(within 12 hours)

more products

News

Featured Products

Contact Details