The difference between stuffing pump and mechanical seal pump

Both packing pumps and mechanical seal pumps are a type of centrifugal pump. There are significant differences in sealing methods, performance characteristics and application scenarios between the two.

1. Sealing method

Filling pump:

The stuffing pump is sealed with packing, which is usually made of some kind of material, such as polytetrafluoroethylene, ceramic, graphite, etc.

The packing is separated from the bearing part of the runner through the seal cavity. When the pump rotates, the packing forms a certain sealing force at the bearing to achieve the purpose of sealing.

Mechanical seal pump:

Mechanically sealed pumps use mechanical sealing technology to achieve sealing, using mechanical and elastic effects to prevent medium leakage.

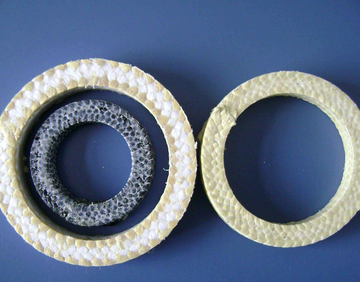

Mechanical seals usually consist of a static ring, a moving ring, a spring, a packing, a sealing ring, etc. The end faces of the static ring and the moving ring fit together, and are equipped with auxiliary seals to form a liquid film to achieve a sealing effect.

2. Performance characteristics

Filling pump:

Because there are many choices of fillers, packing pumps have a wide range of applications when transporting various media, especially when transporting media that are difficult to handle, such as volatile and crystallizing media.

The structure of the filling pump is relatively simple, the manufacturing cost is low, and the maintenance is relatively convenient.

However, the leakage of the packing seal is relatively large, and there is certain wear on the shaft sleeve, and the sealing stability is low.

Mechanical seal pump:

The mechanical seal pump has better sealing performance and small leakage, usually less than 5ml/h, which can meet the high requirements for sealing in high-end fields.

The service life of mechanical seal pumps is relatively long, generally up to more than 1 year, which reduces the frequency of maintenance and replacement.

However, the structure of the mechanical seal is relatively complex, and the manufacturing and maintenance costs are high.

3. Application scenarios

Filling pump:

Filling pumps are often used in petroleum, chemical, pharmaceutical, paper, food and other industries, especially when corrosive liquids containing solid particles or fibers need to be transported in these industries.

Mechanical seal pump:

Mechanical seal pumps are usually used in high-end fields such as urban pipelines, environmental protection industries, thermal power generation, and nuclear power. These fields have high requirements for equipment sealing and stability.

To sum up, there are significant differences between packing pumps and mechanical seal pumps in terms of sealing methods, performance characteristics and application scenarios. When selecting, comprehensive considerations need to be made based on the specific use environment and media characteristics to ensure the normal operation of the equipment and the safety of production.