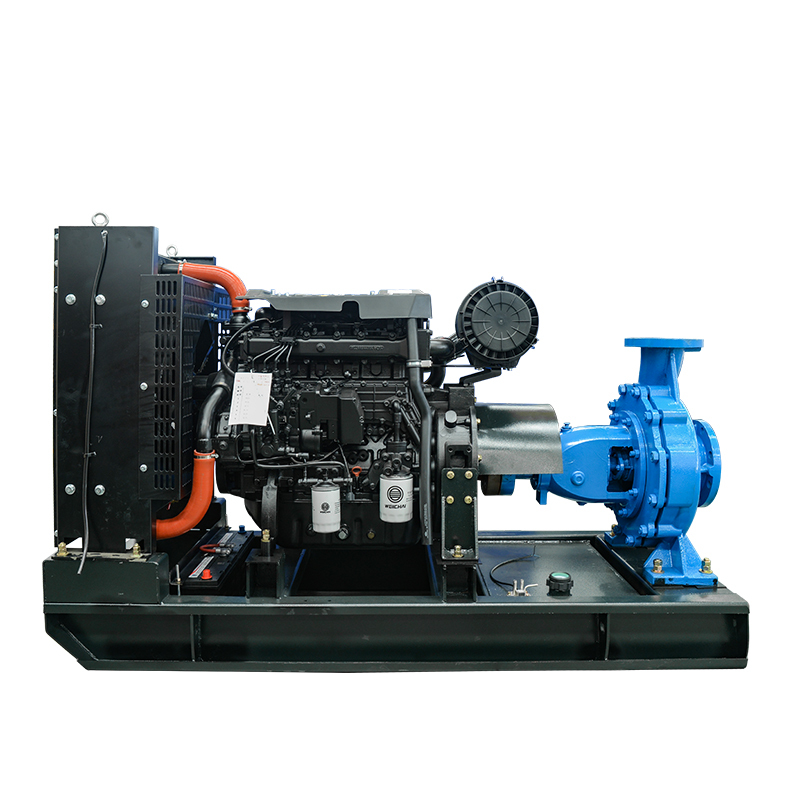

6inch Diesel Egnine Self Priming Sewage Pump With 4 Wheels Trailer

- Gaotian

- Shanghai

- 15days

- 1500

The purpose of a water pump is to transport water from one place to another or to increase pressure by converting mechanical energy into liquid energy. The diesel engine water pump, also known as a diesel engine-driven pump, refers to a pump set driven by a diesel engine through an elastic coupling, which has a reasonable structure, high efficiency, good cavitation performance, low vibration and noise, stable and reliable operation, and easy installation and removal. The liquid discharge outlet on the pump casing is connected to the discharge pipe.

6inch Diesel Egnine Self Priming Sewage Pump With 4 Wheels Trailer

When the pump is operating normally, even pumps with high levels of automation that do not require monitoring should be checked at least once or twice per shift. As mentioned earlier, this is one of the important tasks for early detection of abnormal phenomena. In addition, periodic inspections should also be conducted as needed. The daily inspection contents are as shown in the table, and for some pumps, appropriate selections can be made according to the instruction manual. During routine inspections, in addition to fully operating controls and testing instruments, human subjective initiative should also be exerted, similar to how a traditional Chinese medicine doctor examines patients through observation, listening, questioning, and palpation, to check for any abnormal phenomena with the pump.

6inch Diesel Egnine Self Priming Sewage Pump Technical Specifications

Dimensions

Length x Width x Height (mm) 900 x 600 x 750

Weight (kg) 95

Operating Data

Diameter (suction and pressure pipe) (mm) 150

Total Head (m) 10

Delivery Rate (peak) (L/min) 2500

Suction Height (peak) (m) 8

Engine Data

Cylinder Working Volume (cm³) 496

Engine Power (DIN ISO 3046) (kW) 12.2

At RPM (revolutions per minute) 3600

Fuel Tank Capacity (L) 5.5

Fuel Consumption (L/h) 1.4

Oil Capacity (L) 1.7

The main methods for energy-saving of water pumps include [add specific methods here]. Water pumps are widely used in various fields of industrial and agricultural production, as well as in residential life. The annual electricity consumption of water pump units accounts for more than 21% of the total electricity consumption. Water pumps are also essential auxiliary production equipment for papermaking enterprises, such as for pulping water supply, alkali furnace water supply, coal-fired boiler water supply, etc., and are one of the main energy-consuming equipment in papermaking enterprises.