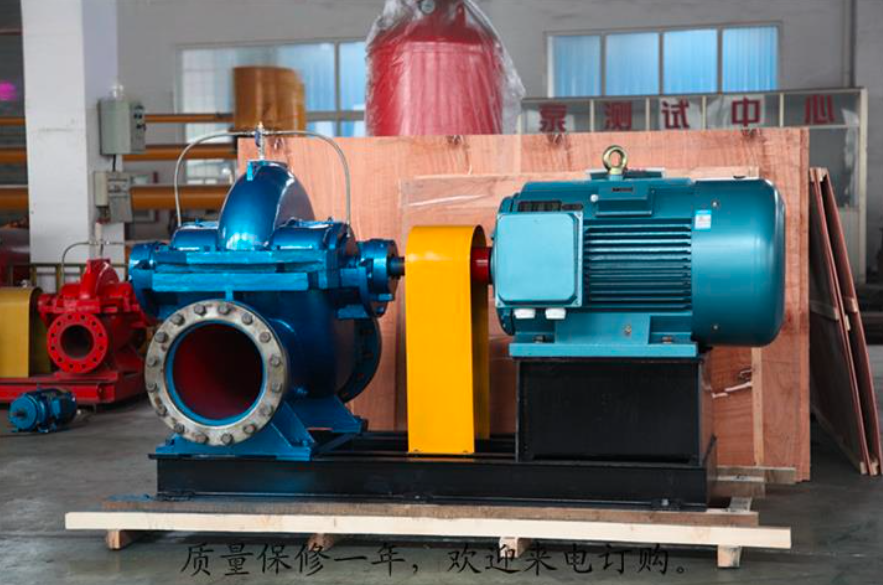

Double Suction Split Case Centrifugal Pump

- Gaotian

- Shanghai

- 15days

- 1500

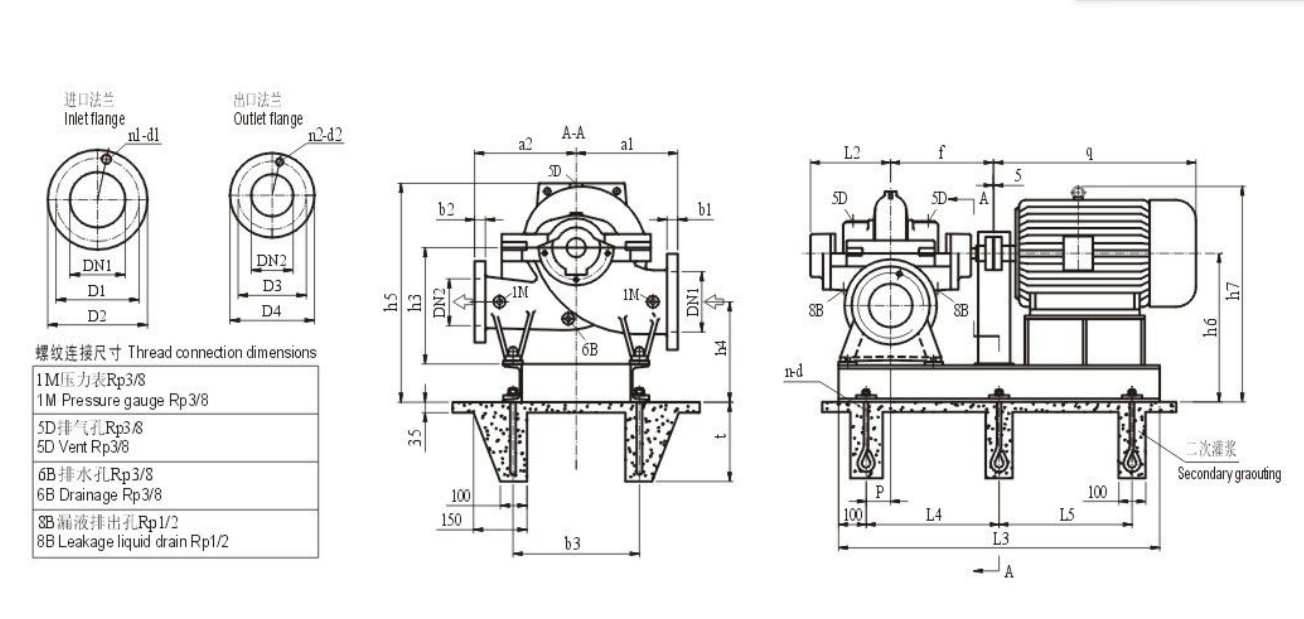

The double-suction center-split pump is horizontally installed, with the suction and discharge ports located below the pump shaft centerline. The pump body is horizontally split, allowing for easy maintenance without the need to dismantle the inlet and outlet pipelines. The shaft seal is a soft packing seal; it can also be changed to a mechanical seal.

The double-suction center-split pump is suitable for industrial and urban water supply and drainage, and can be used as a pump for draining or supplying water in factories, cities, power plants, water conservancy projects, etc. It can also be used for agricultural irrigation. The "S" series pumps are high-efficiency and energy-saving products, characterized by simple structure and excellent performance. They are suitable for transporting clear water or other liquids with physical and chemical properties similar to water and free from solid particles, with a medium temperature ranging from 0°C to 80°C, and an allowable inlet pressure of 0.6MPa.

The structural features of the double suction split case centrifugal pump

1. Horizontally split pump casing for easy maintenance and access to internal components.

2. Double suction impeller design for balanced axial thrust and improved hydraulic efficiency.

3. Centerline discharge for symmetrical flow distribution.

4. Various sealing options such as soft packing or mechanical seals.

5. High-efficiency design for energy savings and performance optimization.

Application areas of the double suction split case centrifugal pump

1. Industrial water supply and drainage systems.

2. Urban water supply and distribution networks.

3. HVAC (heating, ventilation, and air conditioning) systems.

4. Irrigation and agricultural water supply.

5. Power generation plants for cooling water circulation.

6. Municipal water treatment plants.

7. Fire protection systems.

8. Marine and offshore applications.

Technical Advantages of Double Suction Split Case Centrifugal Pump

Advantage 1: High Efficiency

The double suction split case centrifugal pump adopts a structure with interlaced blades, which changes the frequency of the blades and reduces the pulsation of the liquid flow. This leads to smoother liquid flow, higher efficiency, reduced vibration, and more stable and reliable operation.

Advantage 2: Low Pulsation

By introducing the best hydraulic model from domestic and international sources and using CFD (Computational Fluid Dynamics) analysis, the pump's performance surpasses industry standards, achieving international advanced levels with a maximum efficiency breakthrough of over 92%.

Advantage 3: Low Cavitation Allowance

The optimized convex arc-shaped design of the blade inlet edge increases the flow area and lowers the inlet flow velocity, thereby increasing the inlet edge pressure and improving the cavitation allowance. The streamlined design of the blade head reduces liquid flow impact losses and vortices, enhancing efficiency and cavitation performance.

Advantage 4: High Reliability

The high head pump adopts a dual volute design, with reinforced ribs on the pump body and cover. Additionally, ANSYS mechanical analysis software is used to optimize the structure, resulting in a pump casing with high strength and strict water pressure testing according to the GB/T5656 "Technical Conditions for Centrifugal Pumps" standards.

The short bearing span and thickened shaft design minimize rotor disturbance during operation, ensuring stability and reliability. All impellers undergo a 6.3 grade static balance test, while the entire rotor undergoes a 2.5 grade dynamic balance test according to the AP|610 standard.

The main shaft features a fully sealed design that does not come into contact with the liquid, and the bearing components are equipped with a combination sealing structure of lip seals and V-shaped sealing rings, providing excellent leak-proof, dust-proof, water-proof, and moisture-proof capabilities.

Advantage 5: Strong Adaptability

The wide efficient range of the pump can meet a broad range of user requirements. The pump's dual impeller configuration provides excellent selectivity, ensuring that the pump can reach the efficient range for the majority of user operating points.

The pump inlet and outlet flanges can be processed according to GB, ISO, DIN, BS, ANSI, and other standards.

The pump casing flow passage can be coated with ultra-smooth energy-saving coatings, wear-resistant and anti-corrosive coatings, among other options.

For conveying high-temperature media, the pump can be equipped with a Gs-R type structure, and a water-cooled bearing body with central support.

The shaft seal system can achieve interchanging between packing seals and single end face seals, and can be configured with cartridge mechanical seals, double end face mechanical seals, and the AP682 standard flushing system as per user requirements.

The bearing lubrication system offers flexible choices between grease lubrication and thin oil lubrication.

The bearing cooling system allows for a choice between natural cooling and water-cooled bearing bodies based on the temperature of the media.

Remote Monitoring: The bearing body is equipped with monitoring interfaces for temperature and vibration, facilitating remote monitoring.

Advantage 6: High Standardization

With the exception of a few parts such as the pump body, pump cover, and impeller, the remaining components are modularly designed, achieving standardization of parts. Bearing components, sealing components, shaft sleeves, and stuffing boxes in the coaxial system can be interchanged, facilitating mass production of the pump.