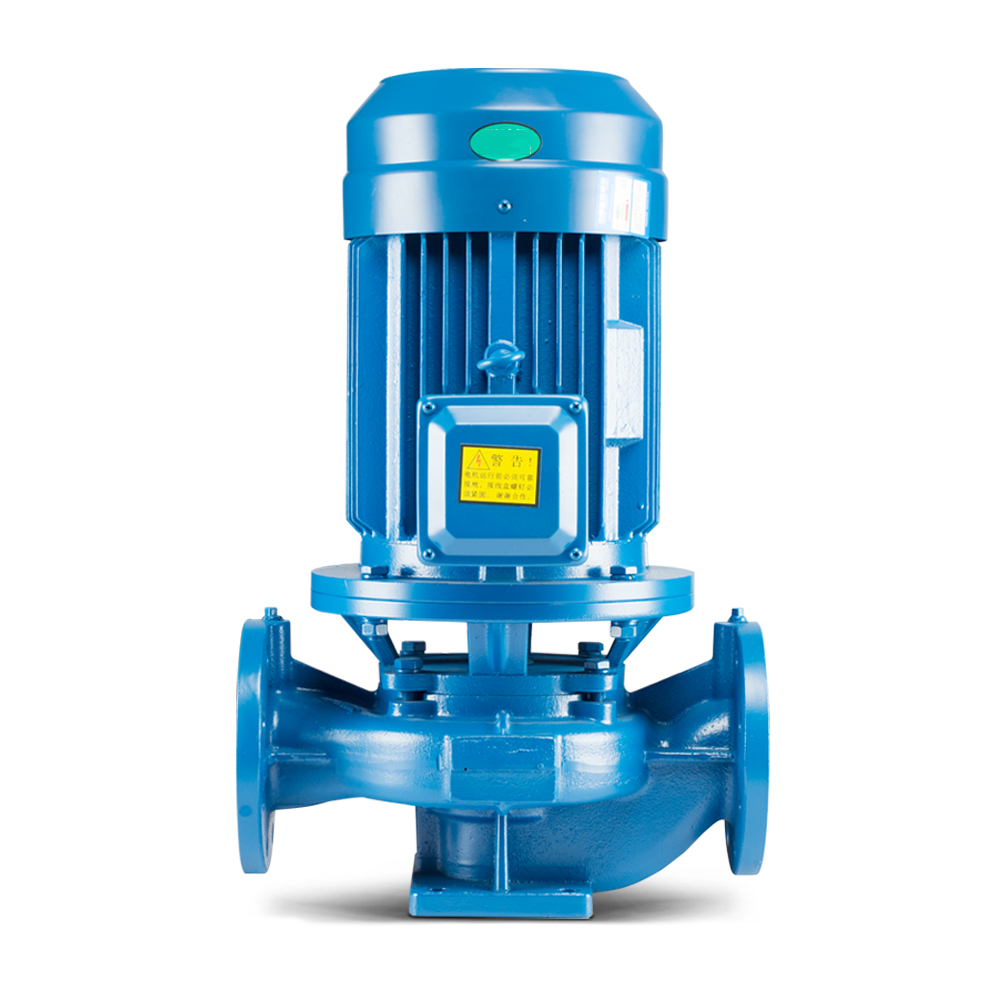

Pipeline centrifugal pump

- Gaotian

- Shanghai

- 7days

- 2000 sets

Why Choose Our Centrifugal Pumps?

Cost-Efficiency: Lower lifecycle costs through durable construction and easy maintenance.

Global Compliance: Adherence to ISO, GB, and international standards for quality assurance.

Technical Support: Expert guidance on installation, troubleshooting, and customization.

Sustainability: Energy-efficient designs reduce operational expenses and carbon footprint.

1. Pipeline centrifugal pump Series Overview

Our centrifugal pump lineup is engineered to meet global industrial standards, offering high efficiency, reliability, and versatility for diverse applications. Designed in compliance with ISO 2858 and GB/T53058-93, these pumps are ideal replacements for traditional SG-series models and deliver superior performance across multiple industries.

ISG/ISW Series: Single-stage single-suction vertical/horizontal pipeline centrifugal pumps with compact design, optimized hydraulic models, and motor-pump integration. Suitable for temperatures up to 80°C.

IRG/GRG Series: High-temperature circulation pumps (up to 240°C) for hot water, steam systems, and industrial thermal processes.

IHG Series: Corrosion-resistant chemical pumps for handling aggressive fluids in petroleum, chemical, and pharmaceutical industries.

YG Series: Oil transfer pumps built for gasoline, diesel, and kerosene, compatible with temperatures from -20°C to 120°C.

ISGB Series: Innovative "easy-disassembly" design with independent bearing support, enhanced durability, and simplified maintenance for industrial and municipal water systems.

2. Key Technical Features of Pipeline centrifugal pump

ISO-Certified Standards: Ensures compatibility and performance consistency with global benchmarks.

Versatile Applications: From water supply and HVAC systems to chemical processing and oil transportation.

Advanced Engineering:

Optimized impellers for reduced axial force and energy loss.

Reinforced materials for high-pressure operation (≤1.6MPa system pressure) and wear resistance.

Modular design allows quick replacement of seals, bearings, and shafts without motor disassembly.

Environmental Adaptability: Operates efficiently in ambient temperatures up to 40°C and humidity below 95%.

3. Pipeline centrifugal pump Applications

HVAC & Building Systems:

High-rise building water supply, cooling tower feed, and fire protection systems.

Chilled/hot water circulation for air conditioning.

Industrial Processes:

Chemical processing (IHG series for corrosive liquids).

Oil refinery and fuel transfer (YG series).

Boiler feed water and thermal power systems (IRG/GRG).

Municipal & Infrastructure:

Municipal water supply, irrigation, and long-distance water transportation.

Wastewater management and pool circulation.

Specialized Solutions:

Abrasive or particulate-containing media (custom wear-resistant seals available).

High-temperature industrial loops (GRG for up to 240°C).

4. Operating Conditions & Customization

Pressure Limits:

Max. suction pressure: 1.0MPa | System working pressure: **≤1.6MPa**.

For pressures exceeding 1.6MPa, custom cast steel components are available upon request.

Fluid Requirements:

Solid particle content: ≤0.1% by volume | Particle size: <0.2mm.

Compatible with clean water, oils, chemicals, and hot fluids (specify temperature during inquiry).

Custom Design Options:

Material upgrades (stainless steel, duplex alloys) for extreme conditions.

Tailored configurations for specific flow, head, or power requirements.