Flameproof Submersible Sewage Pump

- Gaotian

- Shanghai

- 15days

- 1500

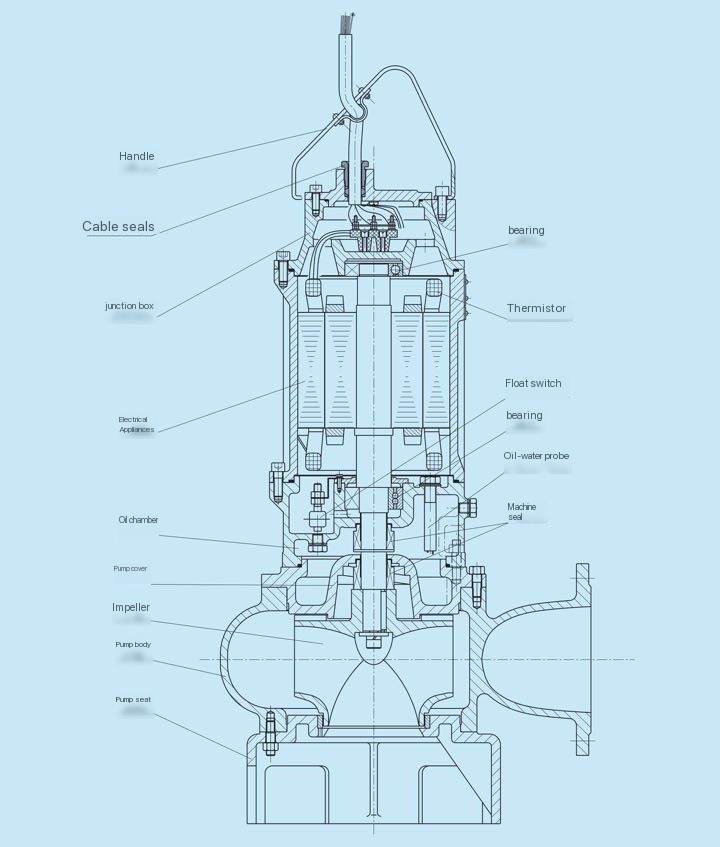

Flameproof Submersible Sewage Pump for coal mines consists of three parts: the motor, the pump section, and the sealing oil chamber. The motor is explosion-proof, with Class B insulation, and the highest allowable winding temperature is 40℃. The sealing oil chamber is located below the motor, and a double end-face mechanical seal is installed at the shaft exit of the rotor. No. 10 machine oil is injected into the oil chamber, and there is a sealing oil plug on the sidewall of the oil chamber.

Characteristics such as high head, large power reserve, good mechanical strength, and easy installation enable reliable isolation of flammable and explosive gases such as methane. It is suitable for drainage in non-mining working faces in coal mines with methane or coal dust explosion hazards.

Flameproof Submersible Sewage Pump structure

The structure of the explosion-proof submersible pump is optimized for improved sealing performance, smooth operation, and high reliability. It is also optimized for lighter weight, ease of use, and low energy consumption. It can run for a long time in the absence of water.

The pump section consists of an impeller, pump body, and water inlet base, with the pump and motor coaxial in a bottom pump structure. The BQW-type explosion-proof submersible sewage pump for coal mines is suitable for discharging sewage in places where methane and coal dust explosion hazards exist. It can be widely used in any working face underground in coal mines to transport underground water containing pollutants, coal dust, mud, and other solid particles.

Operating Conditions for Explosion-proof Submersible Pumps for Mining

1. The flow rate at the outlet of the submersible pump must not exceed the rated value (when used within the specified head range);

2. Transport clean water or mildly polluted water with a fixed content (volume ratio) not exceeding 1%;

3. Submersion depth should not exceed 5 meters. Please declare when ordering if it exceeds 5 meters;

4. Water temperature should not exceed +40℃;

5. pH value should be between 5-9;

6. The volume ratio of solid impurities in the water should not exceed 0.2%, with a particle size not exceeding 2 millimeters;

7. Explosion-proof three-phase AC electric motors for electric pumps should be dry type;

8. Insulation class: B-class, F-class.

Principles of Operation and Explosion-proof Key Points for Explosion-proof Submersible Pumps for Mining

1. When explosive mixtures inside the motor explode, the explosion-proof housing should not be damaged, and it should ensure that internal flames cannot cause explosions of external explosive mixtures through the housing joint surface.

2. When replacing components of the explosion-proof housing, they should be statically tested according to the requirements of GB3836.2 to ensure that they can withstand the highest internal explosion pressure without damage.

3. High-strength fastening bolts and spring washers connecting the explosion-proof housing should not be missing, and the depth of bolt tightening should be 1.25-1.5 times the bolt diameter.

4. Motor bases, end covers (or oil chambers), shafts, terminal box covers, terminal boards, clamping nuts, sealing rings, etc., are explosion-proof parts, and their explosion-proof surfaces should not be knocked or scratched.

5. The insulation resistance between the stator windings and the motor base should not be less than 1000MΩ when cold.

6. The electric pump should not operate submerged in mud and sand. If it is necessary to drain water containing sediment, a bamboo basket or wire mesh should be used to cover the pump to prevent debris from blocking the grid holes, affecting flow, or jamming the impeller, leading to motor overload or poor cooling and resulting in failure.

Flameproof Submersible Sewage Pump section drawing