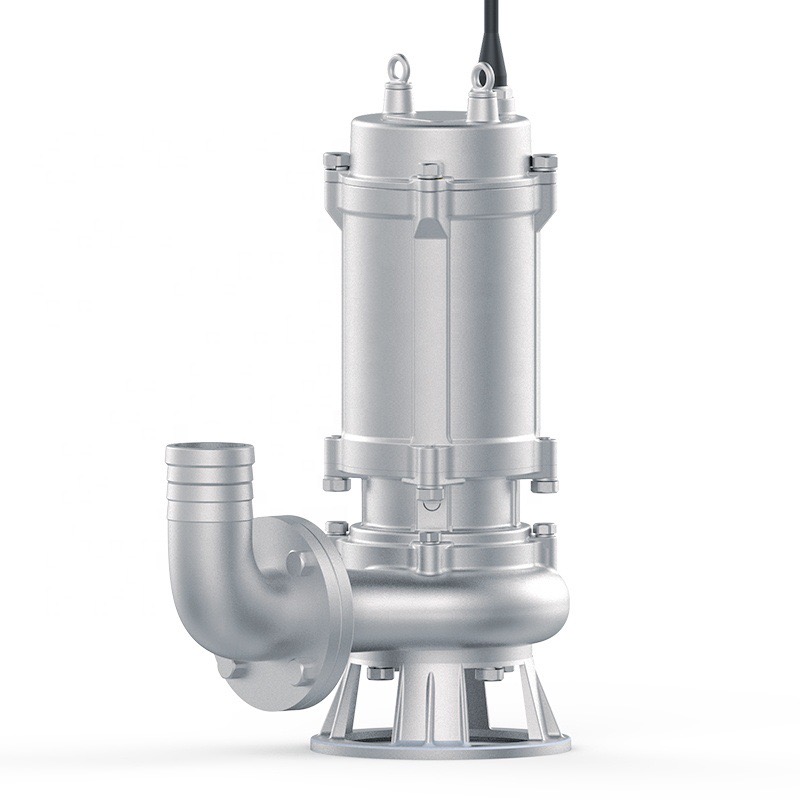

Stainless Steel Precision Casting Submersibles Ewage Pump

Stainless Steel Precision Casting Submersible Sewage Pump (Wire Effluent) is an outstanding product with several highlights:

1. High-Quality Material: Made of high-quality stainless steel material through precision casting, ensuring the product's durability, corrosion resistance, and suitability for use in various harsh environments.

2. Precision Design: Utilizing advanced design and manufacturing processes to ensure the pump's structural stability and smooth operation, providing efficient pumping performance.

3. Submersible Design: Featuring submersible functionality, it can fully immerse in liquids for more efficient and safe pumping solutions.

4. Versatility: Suitable for drainage, sewage treatment, and various other applications, widely used in industrial, agricultural, municipal, and other fields to meet different needs.

5. Low Noise: Incorporating advanced soundproofing technology to reduce operational noise levels, ensuring a comfortable working environment.

6. High Efficiency and Energy Saving: Characterized by high efficiency and energy-saving features, it can reduce energy consumption, save operating costs, and meet the requirements of sustainable development.

7. Reliability: Through rigorous quality control and testing, ensuring stable and reliable product quality, with minimal chances of failure during long-term use, providing customers with peace of mind.

These highlights make the Stainless Steel Precision Casting Submersible Sewage Pump a standout in the industry, offering customers reliable and efficient pumping solutions.

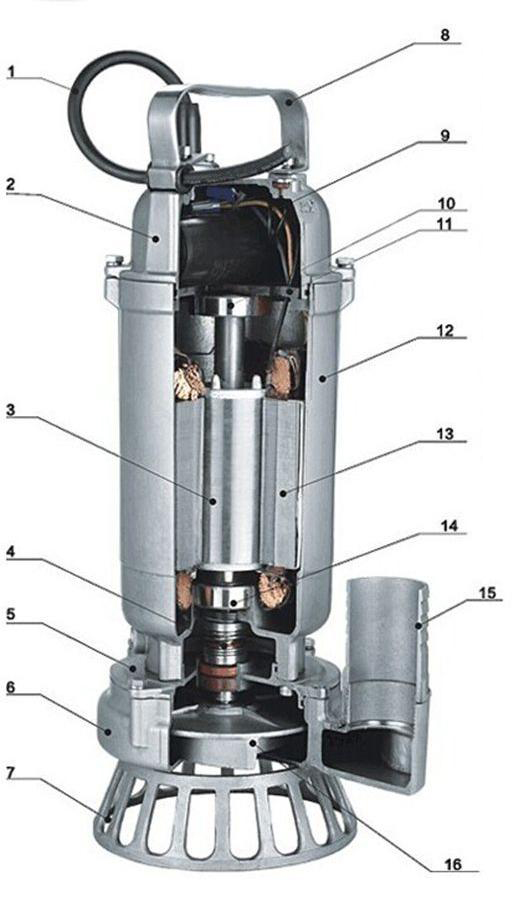

Stainless Steel Precision Casting Submersibles Ewage Pump Structure Composition

The stainless steel submersible pump adopts a single or double vane impeller structure, significantly enhancing its ability to pass debris. It can effectively pass fibrous materials up to 5 times the pump diameter and solid particles with a diameter of about 50% of the pump diameter.

1. Improved Impeller Design: The pump features a single or double vane impeller structure, greatly enhancing its ability to pass debris. It can effectively handle fibrous materials up to 5 times the pump diameter and solid particles with a diameter of approximately 50% of the pump diameter.

2. Durable Mechanical Seal: The mechanical seal utilizes a new type of corrosion-resistant titanium-tungsten material, ensuring the pump's safe continuous operation for over 8000 hours.

3. Compact Design and Energy Efficiency: The overall structure is compact, with a small footprint and low noise. It is energy-efficient and easy to maintain, eliminating the need for a pump house. It can operate by submerging directly into water, significantly reducing construction costs.

4. Advanced Leak Detection System: The pump's seal chamber is equipped with an interference-resistant leak detection sensor, while the stator winding is embedded with a thermal sensing element, providing automatic protection for the pump motor.

5. Automatic Control and Safety Features: It can be equipped with a fully automatic control cabinet according to user needs, providing automatic protection against leaks, electric leakage, overload, and overheating, enhancing product safety and reliability.

6. Float Switch for Convenient Operation: The float switch automatically controls the pump's start and stop based on the required liquid level changes, eliminating the need for constant supervision and ensuring ease of use.

7. Optional Installation Systems: The WQP stainless steel submersible pump can be equipped with a double rail automatic coupling installation system according to user needs, providing greater convenience for installation and maintenance without the need for personnel to enter sewage pits.

8. Wide Operating Range: It can operate within the full head range while ensuring that the motor is not overloaded.

9. Flexible Installation Options: It offers two different installation methods: a fixed automatic coupling installation system and a mobile free installation system.

Stainless Steel Precision Casting Submersibles Ewage Pump Product Application

The stainless steel submersible pump is suitable for industries such as chemical, petroleum, pharmaceuticals, papermaking, cement plants, steel plants, power plants, coal processing industries, as well as municipal sewage treatment plant drainage systems, municipal engineering, construction sites, and other industries for transporting sewage and debris with particles. It is also used for pumping clean water and corrosive media.

Stainless Steel Precision Casting Submersibles Ewage Pump structure photo

1. Cable

2. Top cover

3. Rotor

4. Mechanical seal

5. Oil cylinder cover

6. Pump body

7. Base

8. Lifting handle

9. Capacitor

10. Deep groove ball bearing

11. Upper bearing seat

12. Cylinder

13. Wound stator

14. Deep groove ball bearing

15. Water outlet

16. Impeller