Stainless Steel Precislon Casting Sewage18Automatic Stirring Sewage Pump

- Gaotian

- Shanghai

- 15days

- 1500

Stainless Steel Precislon Casting Sewage18Automatic Stirring Sewage Pump (GB Flange) Features:

1. Capable of Discharging Large Solid Particles

Utilizing a unique single-blade or double-blade impeller structure greatly enhances the ability to pass debris.

2. Long Continuous Operating Time

The mechanical seal employs a new type of corrosion-resistant tungsten carbide material, and the seal is improved to a double-end face seal, allowing it to operate in the oil chamber for extended periods, ensuring the pump can safely run continuously for over 8000 hours.

3. Significant Energy Saving and Low Cost

The compact overall structure, small size, low noise, and significant energy-saving effects make maintenance convenient. No pump room is required, and it can work by submersion in water, greatly reducing project costs.

4. Self-Protection Functionality

The pump's seal chamber is equipped with a high-precision anti-interference water leakage detection sensor, and thermal sensitive devices are embedded in the stator winding to provide absolute protection for the pump motor.

5. Strong Product Safety and Reliability

Can be equipped with a fully automatic safety protection control cabinet according to user needs, providing absolute protection for pump leakage, leakage current, overload, and over temperature, improving product safety and reliability.

6. Intelligent Control, Convenient Supervision

The float switch can automatically control the pump's start and stop according to changes in the required liquid level, eliminating the need for manual supervision and making it extremely convenient to use.

7. Dual Rail Coupling System

Can be equipped with a dual rail automatic coupling installation system according to user needs, greatly facilitating installation and maintenance without the need for personnel to enter the sewage pit.

8. Self-Protection, No Overload

Capable of operating within the entire head range while ensuring the motor is not overloaded.

Stainless Steel Precislon Casting Sewage18Automatic Stirring Sewage Pump (GB Flange) description

Stainless Steel Precislon Casting Sewage18Automatic Stirring Sewage Pump (GB Flange), made of precision-cast stainless steel material, undergoes acid pickling and shot blasting treatment, presenting an aesthetically pleasing appearance and suitable for use in general corrosive environments. The stainless steel sewage pump utilizes a submersible motor and specialized submersible cable, along with a unique structure and new mechanical seal, enabling effective conveyance of solid particles and long fibers, suitable for environments requiring explosion-proof measures. (Note: Due to safety concerns, submersible pumps with cables should not be directly immersed in flammable or explosive liquids, but are suitable for surroundings requiring explosion-proof measures.)

The impeller of the stainless steel sewage pump comes in either single-flow or double-flow form, resembling a section of bent pipe of the same cross-sectional size, providing excellent fluid passage. Coupled with a reasonable volute, this pump achieves high efficiency and undergoes dynamic and static balance tests to ensure vibration-free operation. Developed based on advanced foreign technology and adapted to the usage characteristics of domestic submersible sewage pumps, the stainless steel sewage pump represents a new generation of pump products, featuring significant energy-saving effects, anti-entanglement, non-clogging, automatic installation, and automatic control. It demonstrates unique effectiveness in handling solid particles and long fiber waste.

Stainless steel precision casting wastewater pump Application Scope

1. Discharge of wastewater from industrial units.

2. Discharge systems of urban sewage treatment plants.

3. Drainage stations in subways, basements, and civil defense systems.

4. Wastewater discharge from hospitals, hotels, and high-rise buildings.

5. Sewage drainage stations in residential areas.

6. Discharge of slurry in municipal engineering and construction sites.

7. Water supply devices in water treatment plants.

8. Discharge of wastewater from breeding farms and irrigation of rural farmland.

9. Exploration of mines and supporting water treatment equipment.

10. Replacement of manual labor for carrying and transporting river silt.

11.Usage conditions: Water temperature ≤60°C, liquid pH value between 4 and 10.

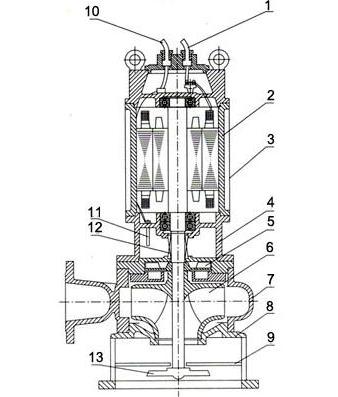

Stainless steel precision casting wastewater pump section drawing

Main cablechassis

Inner circulating sleeve

Fuel tank

Auxiliary impeller

impeller

Pump casing

base

septum

Control cable

Oil and water control head

Mechanical seal

agitator