Anti Acid Chloridric Pump

- Gaotian

- Shanghai

- 15days

- 1500

Anti Acid Chloridric Pump can transport corrosive liquids without solid particles, strong acids, strong alkalis, ethanol, bleach, photographic solution, nitric acid, hydrochloric acid, hydrofluoric acid, acetic acid, sodium hydroxide, acetone, tetrahydrofuran, seawater, saline, etc.

The pump is resistant to corrosion, wear, high temperatures, aging, has high mechanical strength, stable operation, reasonable structure, strict sealing performance, easy disassembly and maintenance, and long service life.

Anti Acid Chloridric Pump Introduction

The Anti Acid Chloridric Pump is a specialized pump designed to handle corrosive fluids such as hydrochloric acid. It is widely used in chemical processing, mining, and other industries where the pumping of corrosive liquids is required.

Anti Acid Chloridric Pump Equipment Features

1. Corrosion Resistance: The pump is made of materials that are highly resistant to corrosion, ensuring long-term reliability when handling acidic fluids.

2. High Durability: The pump is designed to withstand the abrasive nature of corrosive liquids, ensuring a longer service life.

3. Sealing Performance: The pump is equipped with advanced sealing mechanisms to prevent leakage and ensure safe operation.

4. Easy Maintenance: The pump is designed for easy disassembly and maintenance, reducing downtime and maintenance costs.

5. Efficient Operation: The pump is engineered for efficient and stable operation, providing consistent performance in handling corrosive fluids.

6. Long Service Life: With its robust construction and corrosion-resistant materials, the pump offers a long service life, making it a cost-effective solution for handling corrosive liquids.

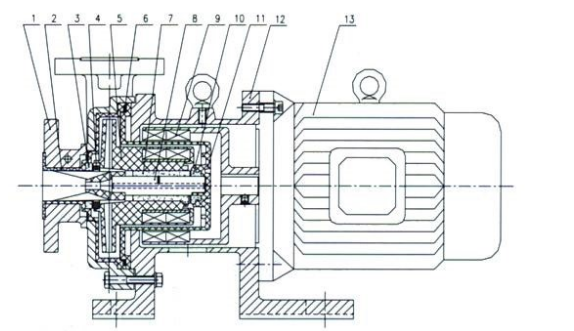

Anti Acid Chloridric Pump structure

1. Imported flange

2. Pump body liner

3. Static ring

4. Dynamic ring

5. Impeller with internal magnetic steel assembly

6. Seal ring

7. Bearing

8. Pump shaft

9. External magnetic steel assembly

10. Thrust ring

11. Isolation sleeve

12. Connecting frame

13. Motor