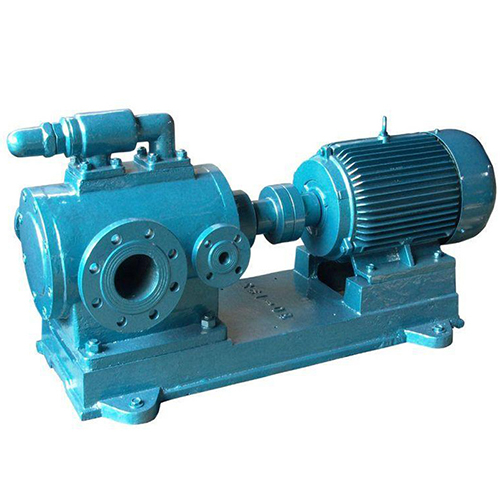

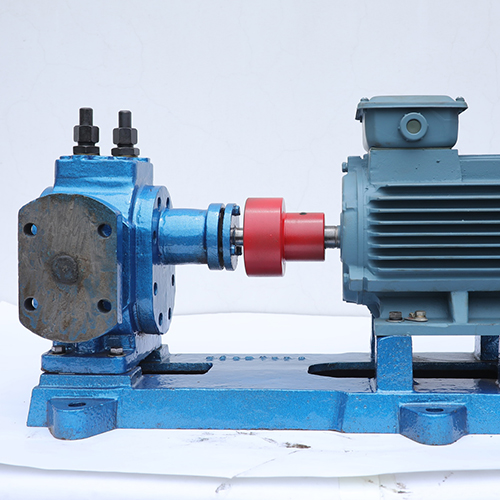

Asphalt Heat Preservation Pump

- Gaotian

- Shanghai

- 15days

- 1500

Asphalt heat preservation pump is an innovative and highly efficient pump that has revolutionized the asphalt heating process. It is designed to reduce energy consumption, increase productivity, and improve safety in the asphalt industry. Here are some of the advantages of using asphalt heat preservation pumps:

Firstly, this pump is equipped with advanced technology that allows it to maintain a consistent temperature for asphalt storage and transportation. This helps to prevent asphalt from cooling down and hardening, ensuring that it remains in a workable state throughout the production process.

Secondly, the asphalt heat preservation pump is highly efficient, minimizing energy consumption and reducing costs for the user. Additionally, it is equipped with a powerful heating system that can quickly heat asphalt to the desired temperature, enabling faster production times and higher productivity.

Thirdly, this pump is designed with safety in mind. It is equipped with numerous safety features, such as automatic temperature control, emergency stop mechanisms, and protective covers, which minimize the risk of accidents and injuries on the job.

Lastly, the asphalt heat preservation pump is easy to operate and maintain. It requires minimal training to use, and the pump’s components are designed to be easily accessible for maintenance and repair. This reduces downtime and increases uptime, allowing for greater productivity and profitability.

Overall, the asphalt heat preservation pump is a highly efficient and innovative solution for asphalt heating and transportation. Its numerous benefits make it the ideal choice for companies looking to improve their asphalt production process, reduce costs, and enhance safety.

Asphalt Heat Preservation Pump:

The working process of the vacuum pump, compressor, and gas-water separator is as follows: the gas enters the 2BV vacuum pump or compressor through the pipeline and valve, and then enters the gas-water separator through the exhaust pipe, and is discharged through the gas-water separator exhaust pipe. When used as a compressor, the gas-water mixture discharged by the compressor is separated in the gas-water separator, and the gas is sent to the system that needs compressed gas through the valve. The working water in the 2BV vacuum pump or compressor is discharged to the vacuum pump without cooling by the gas-water separator and reused. The remaining working water is supplemented by the water supply pipe, and the water supply volume is adjusted by the valve on the water supply pipe.