liquid ring vacuum pump

- Gaotian

- Shanghai

- 15days

- 1500

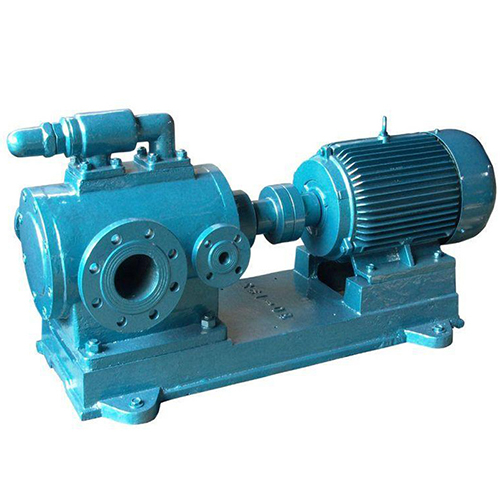

Product Introduction

1. Motor direct-coupled design, saving space, easy installation, and convenient maintenance.

2. All equipped with imported mechanical seals as standard configuration.

3. All have cavitation protection pipe interfaces. When working under extreme pressure, opening the cavitation protection pipe interface (or connecting with the separator) can eliminate cavitation noise to the maximum extent while ensuring the suction effect and protecting the pump.

4. Unique flexible exhaust port design, ensuring optimal efficiency within the performance range without over-compression.

5. All use Y2 series motors with protection class IP54, IP55 (ordinary is IP44), and insulation class F insulation (ordinary is class B insulation).

6. All equipped with imported SKF bearings.

7. The liquid ring vacuum pump can achieve flexible sealing with all polytetrafluoroethylene, greatly extending the service life of the vacuum pump under harsh conditions.

Liquid ring vacuum pump details

The liquid ring vacuum pump is an upgraded product developed based on the traditional water ring vacuum pump in China. It adopts a coaxial direct-coupled design, with high reliability, easy installation and maintenance, and 30% smaller volume compared to traditional vacuum pumps. It operates smoothly, with noise lower than 62 decibels, and has self-priming capability, making it easy to operate. Its oil-free design makes it essentially maintenance-free, and the use of mechanical seals eliminates leaks. The pump is equipped with a gas-water separator, and 50% of the working fluid can be recycled, reducing pollution and operating costs. The pump uses a bronze impeller, improving its corrosion resistance.

According to user requirements, the pump can operate normally in harsh environments when made of stainless steel material. Therefore, it is widely used in industries such as chemical, medical, food, paper, and steel.

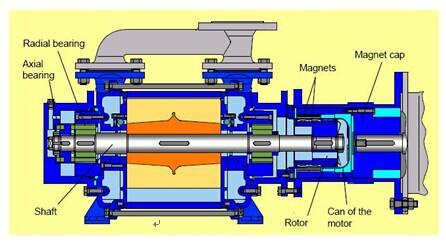

The working principle of a liquid ring vacuum pump

A suitable amount of working fluid is installed in the pump body. When the impeller rotates clockwise, the working fluid is thrown to the periphery by the impeller. Due to the centrifugal force, the liquid forms an approximately uniform thickness closed ring that is determined by the shape of the pump cavity. The upper inner surface of the liquid ring is tangent to the hub of the impeller, and the lower inner surface of the liquid ring just contacts the top of the blades. At this point, the impeller is installed with an eccentricity, forming a crescent-shaped space between the impeller and the liquid ring. This space is divided into several small chambers equal to the number of blades by the impeller. If the upper part of the impeller is taken as the starting point (0 degrees), then when the impeller rotates to 180 degrees, the volume of the small chambers increases from small to large and communicates with the suction port on the end face. At this time, gas is sucked in. When the suction is completed, the small chambers are isolated from the suction port. When the impeller continues to rotate, the small chambers decrease in volume, compressing the gas. When the small chambers communicate with the discharge port, the gas is discharged from the pump.

In summary, the liquid ring pump achieves suction, compression, and discharge by changing the volume of the pump cavity, making it a displacement vacuum pump.