Chemical Transfer Pump

- Gaotian

- Shanghai

- 15days

- 1500

The Chemical Transfer Pump is a single-stage, single-suction (axially) cantilever centrifugal pump designed for the conveyance of liquids without solid particles, with corrosive properties and viscosity similar to water. It follows the equivalent standards per ISO 2858 for markings, rated performance, and dimensions. Characterized by its wide performance range, high efficiency, and user-friendly maintenance, its efficiency is on average 5% higher than that of an F-type pump.

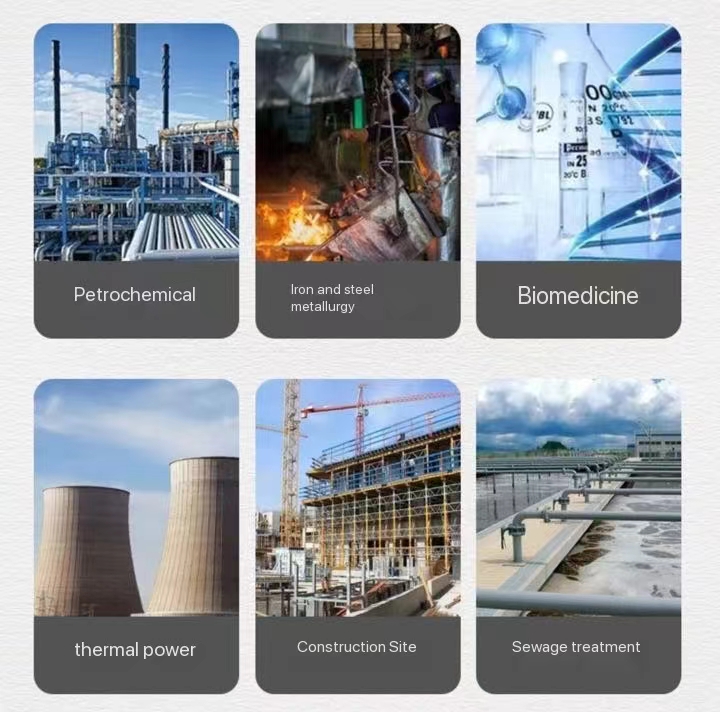

Chemical Transfer Pump Application

The IH stainless steel centrifugal pump operates with a media temperature range of -20°C to 105°C, and a dual-seal cooling system can be employed for higher temperatures up to 300°C. It is suitable for various industries including chemicals, petrochemicals, metallurgy, power generation, papermaking, food, pharmaceuticals, environmental protection, wastewater treatment, and synthetic fiber, for pumping corrosive or non-polluting liquids resembling water.

Chemical Transfer Pump Applications include:

- Oil refineries, petrochemical, coal chemical, and low-temperature industries

- Water treatment plants, desalination facilities, and power plants

- Environmental engineering projects

- Chemical industries, paper and pulp manufacturing, and the sugar industry

It efficiently transports liquids at both low and high temperatures, in neutral or corrosive environments, as well as clear fluids containing solid particles.

The pump cover is secured to the intermediate support frame via a stop surface. It is then compressed between the pump body and the corresponding stop on the support frame. The pump features axial suction and radial discharge, and it is foot-mounted, allowing direct installation on the foundation. The suspension components are fixed to the intermediate support frame with stops and supported by the base frame.

For ease of disassembly, an extended coupling has been designed, enabling maintenance without removing the inlet and outlet piping or the pump body and motor. To inspect the rotor, only the middle connection piece of the coupling needs to be detached.

This design is a commonly adopted international standard. The rotation direction of the stainless steel chemical pump, when driven directly by the electric motor through the extended coupling, is counterclockwise when viewed from the motor end.