Fire Fighting Jockey Pump

- Gaotian

- Shanghai

- 15days

- 1500

Fire Fighting Jockey Pump is an important component of building fire protection systems, which provides stable water pressure and flow for fire water sources. In the event of a fire, the fire stabilizing pump can quickly start and transfer water from the water source to fire facilities, providing powerful firefighting capabilities for firefighters. The working principle of the fire stabilizing pump is to use an electric motor to rotate the impeller of the water pump, thereby transferring water from the water source to fire facilities. The flow and water pressure of the stabilizing pump can be controlled by adjusting the pump's speed to meet different firefighting needs.

The composition and characteristics of a Fire Fighting Jockey Pump

Typically, a fire stabilizing pump consists of a pump body, electric motor, control system, and connecting pipelines.

The pump body is a critical component of the stabilizing pump, containing important parts such as the impeller, pump casing, and mechanical seals.

The electric motor powers the stabilizing pump, while the control system is responsible for monitoring and regulating the pump's operation.

The startup speed of the fire stabilizing pump is crucial in the event of a fire.

To ensure that the fire stabilizing pump can start promptly and provide sufficient water pressure and flow, fire departments often employ measures such as dual power supply and backup power sources to ensure the reliability and stability of the fire stabilizing pump.

Applications of Fire Fighting Jockey Pump

High-rise Buildings

Fire Fighting Jockey Pumps are commonly used in high-rise buildings to maintain the required water pressure in the fire protection system. In tall structures, the water pressure from the mains may not be sufficient to reach the upper floors, making the jockey pump essential for ensuring adequate water supply in case of a fire.

Industrial Facilities

Industrial facilities, such as manufacturing plants and warehouses, often require reliable fire protection systems. Fire Fighting Jockey Pumps play a crucial role in maintaining the pressure in the fire sprinkler system, helping to ensure the safety of personnel and assets in these environments.

Commercial Complexes

Commercial complexes, including shopping malls, office buildings, and hotels, benefit from the installation of Fire Fighting Jockey Pumps. These pumps help to guarantee that the fire suppression systems are always ready to respond to potential fire incidents, providing added safety and security for occupants and visitors.

Hospitals and Healthcare Facilities

In hospitals and healthcare facilities, the reliability of fire protection systems is paramount. Fire Fighting Jockey Pumps are utilized to maintain the necessary water pressure for sprinkler systems, helping to safeguard patients, staff, and valuable medical equipment in the event of a fire.

Data Centers

Data centers house critical and sensitive electronic equipment that must be protected from fire hazards. Fire Fighting Jockey Pumps are employed to ensure that the fire suppression systems are operational at all times, helping to mitigate the risk of fire-related damage to the data center infrastructure.

Educational Institutions

Schools, colleges, and universities prioritize the safety of students and staff. Fire Fighting Jockey Pumps are installed in these institutions to uphold the effectiveness of fire sprinkler systems, providing a proactive approach to fire safety on campus.

Residential Complexes

In residential complexes, such as apartment buildings and condominiums, Fire Fighting Jockey Pumps are used to maintain the water pressure in the fire protection systems. This helps to protect the occupants and property in the event of a fire emergency.

In summary, Fire Fighting Jockey Pumps find widespread application in various settings, ensuring the reliability and readiness of fire protection systems across different types of buildings and facilities.

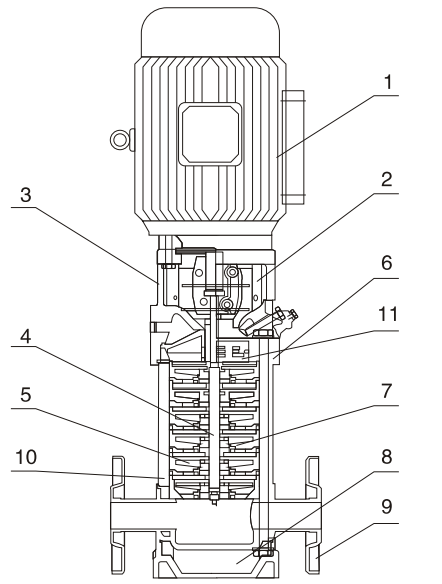

Fire Fighting Jockey Pump section drawing

1. Motor

2. Coupling guard

3. Frame

4. Impeller

5. Intermediate chamber

6. Neck ring

7. Base plate

8. Pump casing

9. Outer jacket

10. Mechanical seal