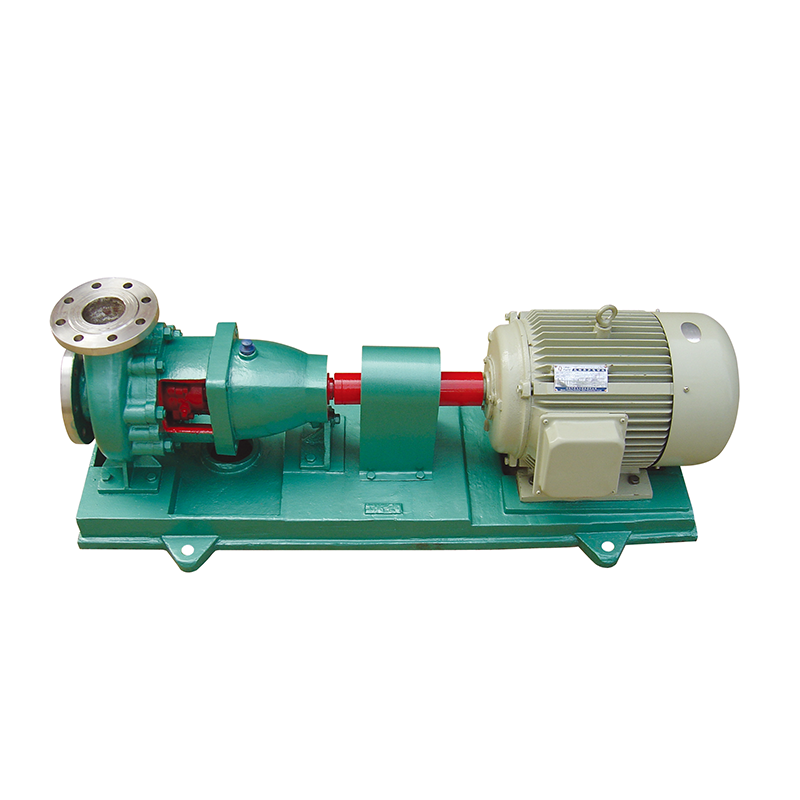

Fluorine Plastic Alloy Centrifugal Pump

- Gaotian

- Shanghai

- 15days

- 1500

Fluorine Plastic Alloy Centrifugal Pump has strong corrosion resistance, high mechanical strength, no aging, no toxic decomposition, and can transport acid, alkali, oxidant and other corrosive media of any concentration. Therefore, it is widely used in chemical, petroleum, pharmaceutical, pesticide, smelting, dyeing, papermaking, electroplating, food and other industries.

Fluorine Plastic Alloy Centrifugal Pump Application

The fluoroplastic alloy centrifugal pump is suitable for a wide range of flow rates and heads. It is commonly used in water pump equipment in industries such as petroleum, chemical, pharmaceutical, pesticide, pickling, dyeing, paint, smelting, papermaking, electroplating, and food.

Advantages of Fluorine Plastic Alloy Centrifugal Pump

The flow part is entirely made of fluorine alloy (including polytetrafluoroethylene and polyvinylidene fluoride, among other fluorine materials, through reasonable formulation) molding and processing. This results in strong corrosion resistance, high mechanical strength, no aging, and no toxic decomposition.

Fluorine Plastic Alloy Centrifugal Pump Shaft Seal

The pump utilizes an externally-mounted PTFE bellows mechanical seal, which has multiple layers of protection, extending the service life of the mechanical seal. For media transportation with impurities, a single end face hard-to-hard (silicon carbide to silicon carbide) mechanical seal without cooling water can be used, thus requiring users to consider the solid content in the medium when selecting the pump.

Features of Fluorine Plastic Alloy Centrifugal Pump

The FSB fluoroplastic alloy centrifugal pump has the flow parts all made of fluoroplastic alloy, with a compact structure, simple operation, and low price. Both models allow for interchangeability of the pump casing, impeller, and seals, making it widely popular among users.

The fluoroplastic alloy pump consists of a pump body, impeller, rear cover, sealing parts, brackets, pump shaft, bearings, couplings, tensioning bolts, nuts, and base plate.

1. Pump Body: The connecting part features embedded steel flange rings on both sides, made of molded plastic alloy.

2. Rear Cover: The right side has an embedded stainless steel plate and is molded with plastic alloy.

3. Impeller: Adopts a shaft connection method with a metal shaft wrapped with molded plastic alloy to integrate the impeller firmly with the shaft, ensuring strong torque force resistance during rotation, with the wetted part being plastic alloy.

4. Mechanical Seal: Utilizes WB2 type, ST type non-cooling water adjustable end face seal technology, made of materials such as silicon carbide, high-purity alumina ceramic, filled with PTFE, graphite, etc.