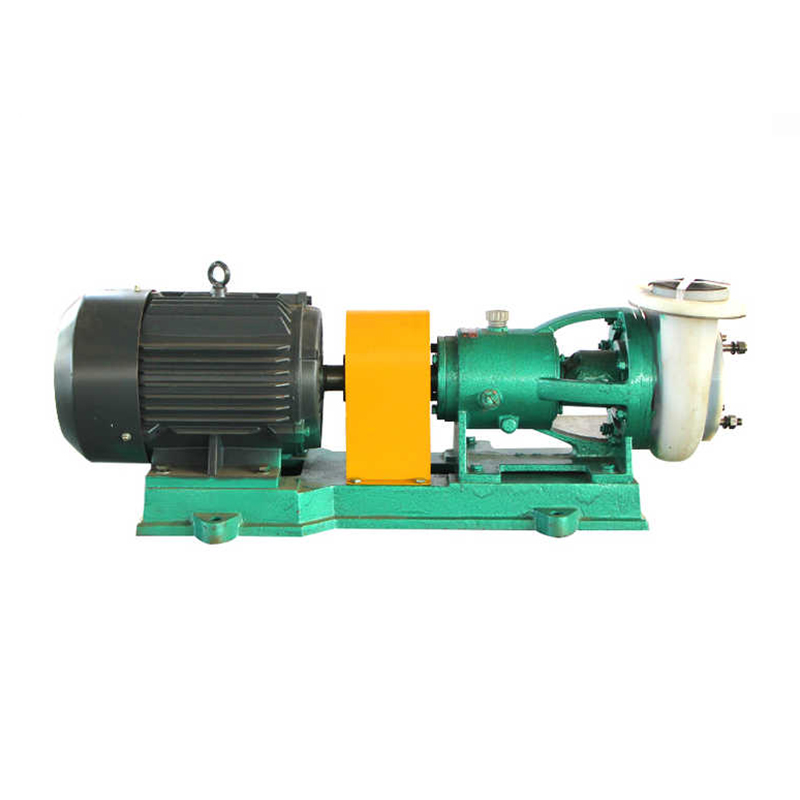

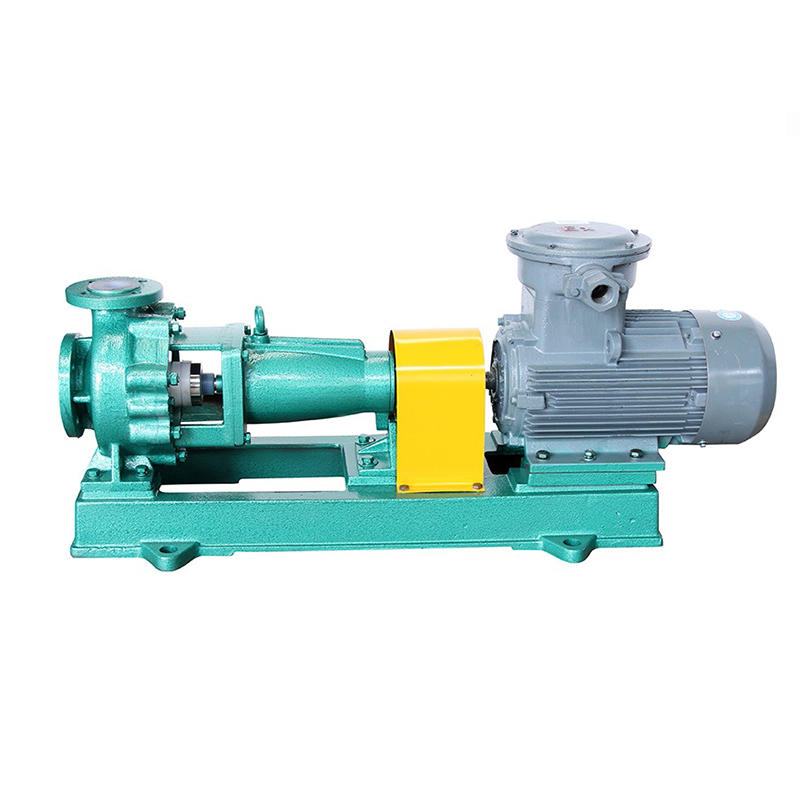

Fluoro Plastic Acid Proof Centrifugal Chemical Pump

The Fluoro Plastic Acid Proof Centrifugal Chemical Pump is a type of horizontal centrifugal pump that is highly resistant to strong corrosion. The pump body is made of a metal shell lined with polyvinylidene fluoride (F46). The pump cover, impeller, and shaft sleeve are all made of metal inserts wrapped in fluoroplastic and then sintered and molded. The shaft seal uses an externally mounted bellows mechanical seal, with the stationary ring made of 99% alumina ceramic or silicon nitride, and the moving ring made of PTFE filler material, ensuring resistance to corrosion and wear, making it one of the strongest corrosion-resistant equipment currently available. Its advantages include a compact and reasonable structure, high resistance to strong corrosion, reliable sealing performance, low noise, high mechanical strength, non-aging, convenient maintenance, smooth flow path, high efficiency, and energy savings.

Fluoro Plastic Acid Proof Centrifugal Chemical Pump Structure

The fluoroplastic alloy centrifugal pump consists of a pump body, impeller, back cover, sealing components, support, pump shaft, bearings, couplings, bolts, nuts, and base plate.

1. Pump body: Steel flange rings are embedded on both sides of the connecting part and made of molded plastic alloy.

2. Back cover: A stainless steel plate is embedded on the right side and made of molded plastic alloy.

3. Impeller: It is connected to the shaft using a linking method, where the metal shaft is precision machined steel wrapped with molded plastic alloy, ensuring a strong connection between the impeller and the metal shaft. The shaft root and the rear part of the impeller bear the torque force during rotation, making the wetted part of the medium made of plastic alloy.

4. Mechanical seal: It adopts WB2 type, ST type non-cooling water adjustable end-face sealing technology, made of silicon carbide, high-purity alumina ceramic, filled with PTFE, graphite and other materials.

Fluoro Plastic Acid Proof Centrifugal Chemical Pump Application Range

The excellent structure of the fluoroplastic alloy centrifugal pump reduces phenomena such as running, leaking, dripping, and seepage. It is widely used in the chemical industry, acid manufacturing, alkali manufacturing, metallurgy, rare earth, pesticides, dyes, pharmaceuticals, papermaking, electroplating, electrolysis, pickling, radio, chemical foil production, research institutions, and the defense industry. It can be used to transport highly corrosive media under harsh conditions, such as acetic acid, strong alkalis, strong oxidizing agents, organic solvents, and reducing agents, at temperatures ranging from -80 to 150 degrees Celsius.