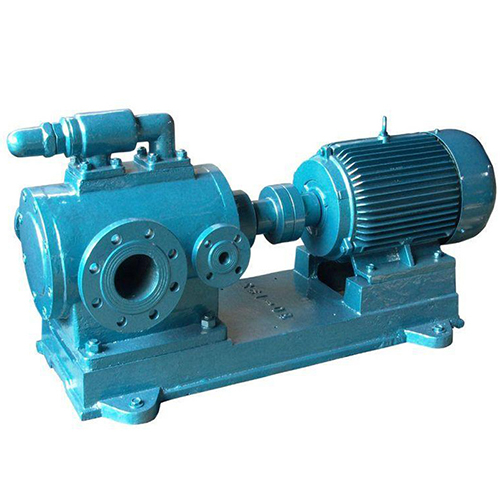

High Viscosity Asphalt Cement Pump

- Gaotian

- Shanghai

- 15days

- 1500

The pump chamber consists of the pump body, rotor, and pump front cover. Under the drive of the synchronous gears, the two rotors move in opposite directions inside the pump chamber. As a result, the volume of the pump inlet chamber gradually increases, creating a vacuum that instantly fills every corner of the inlet chamber with the medium: at this point, the volume of the pump outlet chamber gradually decreases, forcing the medium to flow out of the pump chamber, thereby achieving the purpose of conveying the medium.

High Viscosity Asphalt Cement Pump Features

1. The flow parts of this pump are all made of the most advanced high-quality wear-resistant materials internationally, and the heat treatment process currently used internationally is also employed. This greatly enhances the pump's wear resistance, extending its service life several times longer compared to alternatives such as screw pumps, gear pumps, heavy oil pumps, and Roots pumps, thereby significantly increasing the pump's operating cycle and reducing usage costs.

2. The pump seal adopts a combination seal. Previous single seals performed poorly with high-viscosity asphalt. To address this, our company has developed a new type of combination seal specifically for high-viscosity asphalt, ensuring reliable sealing performance.

3. Special design of linear rotors adjusts the sealing contact area between the specially designed rotors and between the rotor and pump body, improving the pump's volumetric efficiency. The rotor design includes two-leaf and three-leaf options, with various blade designs such as straight blades and helical blades to meet various user requirements under different working conditions.

4. This pump adopts a unique cantilever structure, effectively reducing a potential sealing leakage point on the left pump cover. An independent gearbox is used, providing separate lubrication for gears and bearings with lubricating oil, ensuring that no medium enters the gearbox in case of seal leakage, thereby increasing the pump's service life.

5. Speed reduction transmission is achieved through a large speed ratio reducer, enabling the pump to operate at low speeds, further increasing its service life, reducing pulsation, and improving operational stability.

6. All clearances between rotors and between rotors and the pump body are maintained within a reasonable range during pump operation, reducing internal leakage and improving the sealing between the discharge and suction chambers. Thus, the pump has good self-priming ability, with a vacuum degree of up to 5 meters or more.

7. After shutdown, asphalt may solidify inside the pump chamber. If the pump is not sufficiently preheated before restarting, not only will the torque increase during motor startup, but it will also damage the surface structure of the sealing ring, seriously affecting the overall service life of the pump. Therefore, to address this issue, the pump increases the volume of the pump body insulation chamber and the area of heating insulation, ensuring more thorough preheating and reducing preheating time.

8. This pump is extremely easy to maintain and can be cleaned or repaired online without dismantling the pipeline, reducing ongoing maintenance costs.

9. Pump flow rate is proportional to speed and can be controlled by frequency conversion according to customer requirements, simultaneously reducing energy consumption.

High Viscosity Asphalt Cement Pump Technical Features

Due to the characteristics of high-viscosity asphalt, which combines the high viscosity of asphalt with the characteristics of solid-liquid multiphase mixed media, there are extremely high requirements for the pump's wear resistance and sealing reliability in the transportation process. Therefore, numerous research institutions, pump manufacturers, and end users have been unable to solve this pumping problem, forcing many enterprises to resort to alternatives such as screw pumps, gear pumps, heavy oil pumps, or Roots pumps. Due to the limitations of their own structures and the materials of the flow parts, none of them can meet the requirements for transporting asphalt mixtures. They often become unusable after only one to two months of normal operation due to excessive wear of the flow parts, and their sealing performance cannot meet the requirements. Often, newly installed pumps leak or are damaged shortly after being put into use.

In view of this, guided by the concept of creating value for customers, our company's technical personnel conducted in-depth investigations and research, combined with customer feedback; engaged in technical exchanges with materials science experts from professional research institutions such as the Institute of Metal Research of the Chinese Academy of Sciences multiple times; summarized the shortcomings of previous products in terms of technology and materials; and finally conducted comprehensive optimization design to develop a dedicated pump for transporting liquid high-viscosity asphalt—High-Viscosity Asphalt Pump.

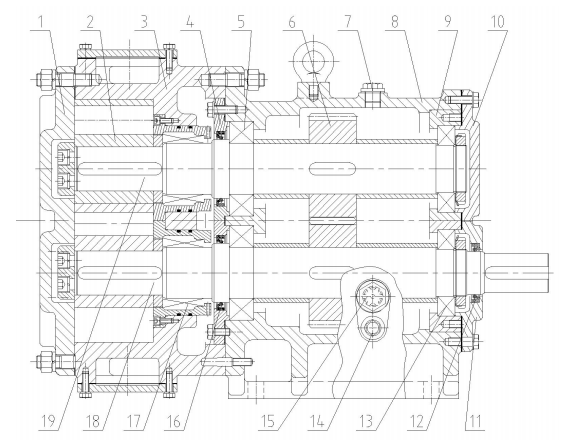

High Viscosity Asphalt Cement Pump section drawing

1. Front cover 2. Rotor 3. Pump body 4. Bearing cover 5. Bearing 6. Gear 7. Oil injection hole 8. Casing 9. Bearing sleeve 10. Non-hole bearing cover 11. Hole-bearing cover 12. Skeleton oil seal 13. Bearing 14. Oil drain plug 15. Draining window 16. Skeleton oil seal 17. Mechanical seal 18. Active shaft 19. Driven shaft