Horizontal multistage centrifugal pump

- GAOTIAN

- China

- 15days

- 3000

This series of pump is of sub-horizontal,multi-stage single-suction and centrifugal,using state-recommended hydro-module.The pump is efficient,reliable,and durable with lownoise performance ,easy maintenance and wide scope ofusages.We specialize in manufacturing D,DF,DY and MD seriesof single-suction multistage centrifugal pumps based on our20 years plus history and fame of biggest multistage pumpmanufacturer in Middle-Southern Area .Our pumps are widelyapplicable.

Our pump is applicable to deliver those fluid withoutsolid,particles or any other suspended stuff,water forinstance.While oily and corrosive or solid-contained fluid canbe pumped by means of material modification,sealingmethods,and cooling system adding.

The max,inlet pressure shall be 0.6MPa.

Horizontal multistage centrifugal pump Overview

1.General description

This series of pump is of sub-horizontal,multi-stage single-suction and centrifugal,using state-recommended hydro-module.The pump is efficient,reliable,and durable with lownoise performance ,easy maintenance and wide scope ofusages.We specialize in manufacturing D,DF,DY and MD seriesof single-suction multistage centrifugal pumps based on our20 years plus history and fame of biggest multistage pumpmanufacturer in Middle-Southern Area .Our pumps are widely applicable.

Our pump is applicable to deliver those fluid without solid,particles or any other suspended stuff,water forinstance.While oily and corrosive or solid-contained fluid canbe pumped by means of material modification,sealing methods,and cooling system adding.

The max,inlet pressure shall be 0.6MPa.

Technical Features

High efficiency and Energy saving We have developed our unique technology for manufacturing,model designing and making,foundry techniques of hydraulic parts in that we take advantage of precise foundry on all wets parts to assure theirbrightness,cleanliness,and accurate dimensions.So the pump has very good Energy-saving effect.

Advanced process equipment

Every single processed part will have cleaned by means of advanced imported cleaning equipment for better assembling concern.Besides material inspection,hydraulic test,static balancing testing,all pump rotors beyond 6 grades will haveaxial movement tested controlled within 5 millisecond,and then the balancing test shall be made according to G2.5grade.Recheck axial movements of all shafts after assembly to assure the quality of the pump.

Unique structure

A sealing O-ring is set between balancing ring and fitting surface of the pump to avoid high pressure water coming into balancing stage and wear and tear of the balancing plate to obtain better durability.Wear indicator of balancing plate is setat the end of the shaft for wear monitoring for pumps beyond DN200.This makes the replacement of balancing platereasonably to assure fine operation.

Material choosing

Balancing plate and the area around can be made of welding alloy,alloy steel or ductile cast iron QT600Mn2 concerning their high surficial hardness and fine durability,Flowing-over part of MD pump is of abrasion resistant by using material of alloy wear resistant ductile castiron orhigh-qrade wear-resistant ductile cast iron.

Fine appearance

The appearance of the pump is fine taking advantage of precise mold casting procedures and automatic painting.

2.proNomenclature

EX:D(DF、DY、MD)600-60x6

D--multi-stage clean water centrifugal pump

DF--corrosion-resistant multi-stage centrifugal mining pump

DY--multi-stage centrifugal oil pump

MD--wear-resistant multi-stage centrifugal mining pump

600--the design point of capacity is 600m° /h

60--the design point of single-stage head is 60m

6 --the pump stage is 6

EX: 150 MD 30x7

150--the pump inlet diameteris 150mm

MD--wear-resistant multi-stage centrifugal mining pump30--the design point of single-stage head is 30m7 --the pump stage is 7

Note:D(DF.DY.MD)80-30is the customary method,of which 80 means the inlet diameter is 80mm,30 means single-stage pump design point head is 30m,others meaningis the same method as above.

3.Performance Range

D、DF、DY、MD-type pump has the same performance parameters and installation size Inlet and outlet diameter ofthe pump:40~300mm CapacityQ=3.75-850m*/h

Head H=19~816m

Note:The performance parameters in this book are the normal temperature water testing values.

4.Auxiliary Motor

Y series of motors are for common use,Explosive-proot motor is a must under circumstances of inflammable and explosive while insulation class and explosive-proof markshall be indicated.

5.Executive Standard

GB/T5657-1995 Technical Specifaications of Centrifugal Pump(Cat.ll)

JB/T1051-2006 Type and Basic Parameters of Multi-level Fresh Water Centrifugal Pump

GB/T3216-2005 Hydraulic Performance Acceptance Test of Rotodynamic Pumps Level 1 and Level 2

MT/T114-2005 Coal Mine Multi-stage Centrifugal Tump

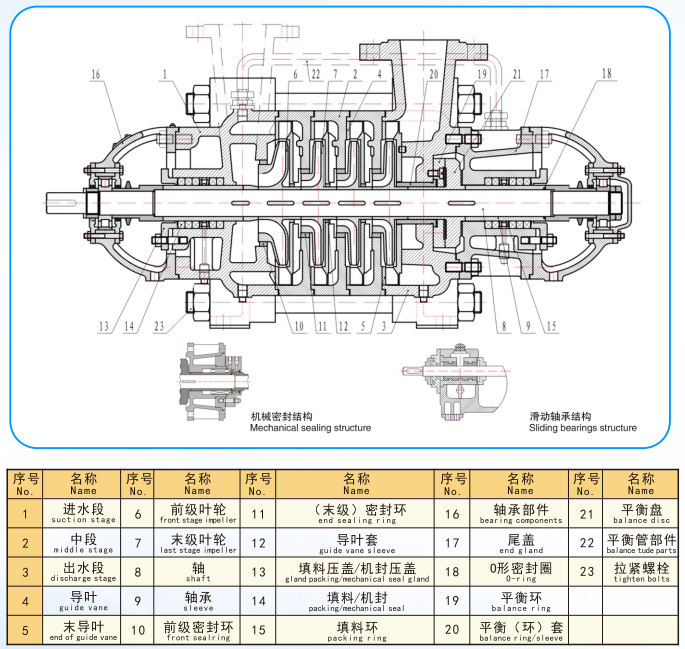

6.Structure diagram

7.Horizontal multistage centrifugal pump real photo