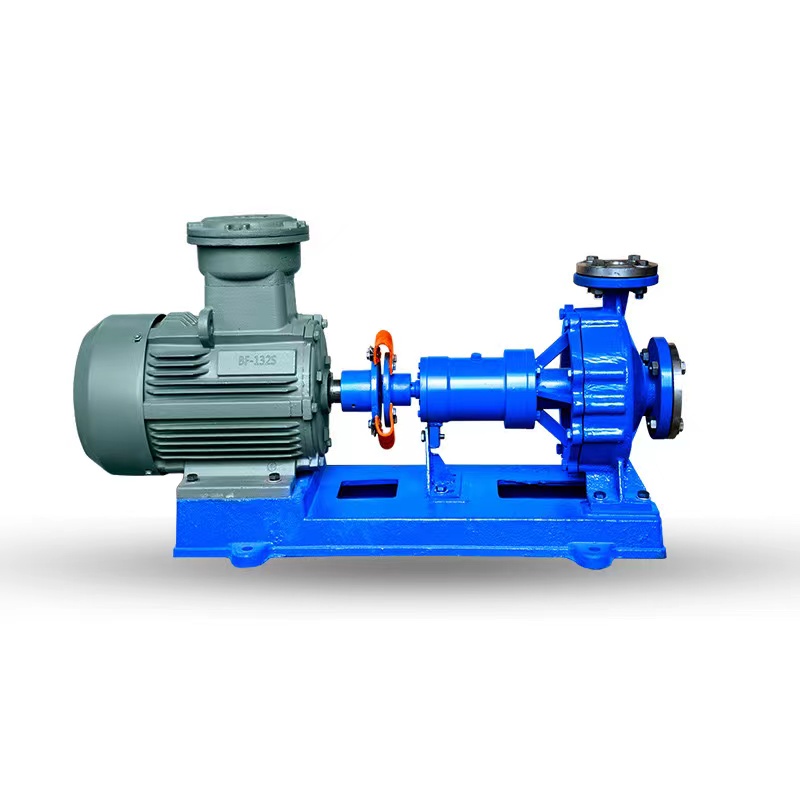

Hot Oil Pumps

- Gaotian

- Shanghai

- 15days

- 1500

Advantages of Hot Oil Pump:

• Unrivalled mechanical strength and stiffness resulting from optimally arranged stiffening ribs‚ a large centering diameter and an optimized angle

• Large sealing space volume to flush shaft seal‚ including patented device to strip gas bubbles from the seal to avoid dry running

• Housing parts are constructed of ductile iron for high operational safety

• Available with shaft sealing or mechanically-coupled system

• Antifriction bearing with guard disc and grease for long service life

Hot oil pump is developed by absorbing the characteristics of various advanced thermal oil circulation pumps at home and abroad. The pump has the characteristics of reasonable structure, advanced technology, high efficiency, stable operation without leakage for a long time in hot state, and reliable safety without additional cooling system. It can be widely used in industries such as petroleum, grease, boilers, construction, roads, pharmaceuticals, plastics, rubber, fiber-containing textiles, printing and dyeing, etc. It is an ideal thermal carrier medium circulation pump with a maximum operating temperature of ≤370°C.

(1) Hot oil pump adopts a combination of packing seal and mechanical seal. The packing seal uses high-temperature resistant packing with good thermal adaptability, while the mechanical seal uses hard alloy materials with high mechanical strength and good wear resistance to ensure sealing performance under high temperature conditions.

(2) Hot oil pump uses imported polytetrafluoroethylene (PTFE) as the lip seal, which greatly improves the sealing performance. Compared with rubber seals, the reliability is increased by 25 times, and it has extremely strong corrosion resistance.

Application of Hot Oil Pumps

Hot oil pumps capable of handling temperatures up to 370˚C in heat transfer plants without the necessity for external cooling of the pump. The fluids pumped must have lubricating properties and should not contain any solids or abrasive particles, as the non drive end bearing and mechanical seal is lubricated by the pumped liquid.

• Chemical and Pharmaceutical Industry

• Mineral Oil

• Food, Laundries and Textile

• Leather and Paper

• Wood Manufacturing

• Paint and Lacquer

• Building, Tar and Bitumen

• Electrical Engineering Industries

Transporting edible oil

Transporting thermal oil

Conveying engine oil

Conveying transformer oil