Large Flow Water Pump

- Gaotian

- Shanghai

- 15days

- 1500

Large Flow Water Pump are constructed in single stage single suction volute casing, applicable to clean water or sewage water without solid for a temperature below 80 C, which is ideal for farmland irrigation, water supply and drainage in industrial and urban projects.

Structure and Application of Large Flow Pump

Large flow pumps are essential components in various industries where there is a need to transfer substantial volumes of liquids efficiently. These pumps are characterized by their robust construction and high-performance capabilities, making them suitable for a wide range of applications across different sectors.

Structure

Large flow pumps typically consist of several key components designed to facilitate the movement of fluids. The primary elements include the pump casing, impeller, shaft, bearings, and motor. The pump casing encloses the impeller and serves as a conduit for the liquid flow. The impeller, driven by the motor, generates centrifugal force, which propels the fluid through the pump. The shaft connects the impeller to the motor, transmitting the rotational energy. Bearings support the shaft, ensuring smooth operation and reducing friction. Additionally, large flow pumps may incorporate features such as multiple stages or variable speed drives to enhance efficiency and performance.

Application Range

Large flow pumps find extensive applications across various industries due to their ability to handle significant volumes of liquids efficiently. Some common areas of application include:

Water Management:Large flow pumps are widely used in water treatment plants, wastewater management systems, and irrigation schemes to transport water from one location to another. They play a crucial role in ensuring adequate water supply and maintaining environmental sustainability.

Mining and Construction: In mining operations and construction sites, large flow pumps are utilized for dewatering applications to remove excess water from excavation sites or underground tunnels. They aid in groundwater control, facilitating safe and efficient working conditions.

Chemical Processing:Large flow pumps are employed in chemical processing industries for transferring various liquids, including corrosive chemicals, solvents, and acids. Their robust construction and corrosion-resistant materials ensure reliable operation and long-term performance in demanding environments.

Oil and Gas:Within the oil and gas sector, large flow pumps are essential for transporting crude oil, refined products, and wastewater during extraction, refining, and distribution processes. They contribute to the efficient operation of pipelines, refineries, and storage facilities.

Power Generation:In power plants, large flow pumps are utilized for circulating cooling water, boiler feedwater, and condensate, playing a critical role in the thermal management of equipment such as turbines and generators. They help maintain optimal operating conditions and maximize energy output.

In conclusion, large flow pumps represent indispensable equipment across a diverse range of industries, offering efficient fluid handling solutions for various applications. With their robust construction, high-performance capabilities, and versatility, these pumps continue to play a vital role in facilitating industrial processes and infrastructure development worldwide.

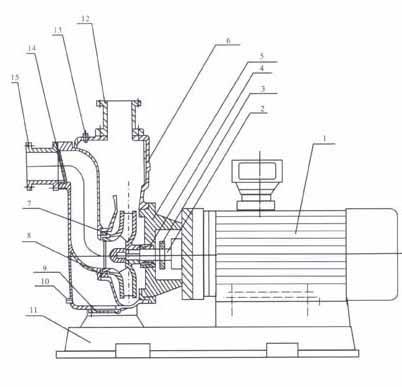

Large Flow Pump section drawing

1. Motor: Directly connected to the pump to transmit power, utilizing branded motors.

2. Pump Shaft:Coaxial with the motor, ensuring concentricity and smooth, noise-free, and vibration-free pump operation. Chrome plating enhances longevity.

3. Water Deflector Ring: Prevents water ingress into the motor due to seal leakage.

4. Mechanical Seal: Constructed from stainless steel, tungsten carbide, fluorine rubber, etc. Balanced, high-temperature, and high-pressure mechanical seal with long operational life, leak-proof, no shaft wear, no scale accumulation, ensuring a tidy working environment.

5. Pump Cover: Connects the pump body and motor.

6. Pump Body: The pressurized chamber, suction chamber, and gas-liquid separation chamber are designed with high-quality hydraulic models, both aesthetically pleasing and efficient, with installation feet for stable mounting and operation.

7. Impeller: Designed with advanced hydraulic models, characterized by high efficiency and reliability.

8. Sealing Ring: Provides sealing at the junction between the pump impeller and body.

9. Bottom Cover Plate: Allows cleaning of debris when sediment accumulates inside the pump body.

10. Drain Plug: Allows draining of stored liquid when the pump is not in use.

11. Baseplate: Connects the entire pump for installation, also suitable for installing vibration isolators.

12. Outlet Pipe Connection: Connects to the outlet pipeline.

13. Water Inlet Valve: Opens the valve to add water when the pump chamber lacks fluid.

14. Check Valve Flap: Prevents water from flowing back into the pipeline when the pump is not operating.

15. Inlet Pipe Connection: Connects to the inlet pipeline.

These components collectively contribute to the efficient operation and reliability of large flow pumps, making them indispensable in various industrial applications.