Magnetic Drive Pump

- Gaotian

- Shanghai

- 15days

- 1500

1.Smooth transmission, no pulse, accurate measurement;

2.Use magnetic drive structure, static seal, truly achieve zero leakage;

3.Diversified drive, wide application in the industry, complete models;

4.High efficiency and energy saving, easy maintenance, low installation cost and long service life.

Magnetic Drive Pump Introduction

The magnetic pump is a branch of the water pump field, which is a new product that applies the working principle of permanent magnetic coupling to centrifugal pumps.

Magnetic pumps are divided into types such as AC micro, brushed DC, and brushless DC, and have characteristics such as fully sealed, leak-proof, and corrosion-resistant. They consist of a pump, magnetic drive, and motor. The magnetic drive of the magnetic pump consists of an outer magnetic rotor, an inner magnetic rotor, and a non-magnetic isolation sleeve. When the motor drives the outer magnetic rotor to rotate, the magnetic field can penetrate air gaps and non-magnetic materials, driving the inner magnetic rotor connected to the impeller to rotate synchronously, achieving contactless synchronous power transmission and transforming the easily leakable dynamic seal structure into a zero-leakage static seal structure. Since the sliding bearings of the magnetic pump are lubricated with the conveyed medium, bearings made of different materials should be selected according to the different media and operating conditions.

Magnetic Drive Pump characteristics

• dianResistant to strong acids and alkalis: Injection molded with pure FRPP/CFRPP/PVDF plastic materials, different materials can be selected based on the chemical properties required by the customer.

• Wide range of applications: Suitable for electroplating, coating, etching, surface treatment, laboratories, chemical processes, etc., can withstand most chemical substances, suitable for various acid and alkali liquid transportation operations.

• Special Teflon elastic shaft seal design, paired with variodianus materials of shaft seals such as ceramics, carbon fine, SSIC, and Hastelloy-C alloy spring, with excellent durability and corrosion resistance.

• Structural design: The base formed by plastic injection molding is lightweight and corrosion-resistant.

Magnetic Drive Pump characteristics components

A magnetic drive pump consists of three main components: the pump body, magnetic coupling, and motor. The key elements of the magnetic transmission are the outer magnetic rotor, inner magnetic rotor, and a non-magnetic isolation sleeve. When the motor rotates the outer rotor, the magnetic field passes through the air gap and non-magnetic materials, synchronously turning the inner rotor connected to the impeller without physical contact, transferring power efficiently. This creates a static seal. The design ensures that the pump shaft and inner rotor are fully enclosed by the pump housing and isolation sleeve, preventing leaks of flammable, explosive, toxic, or harmful substances, thus eliminating potential safety hazards.

Magnetic Drive Pump characteristics applications

Magnetic pumps find extensive applications in various industries, such as computer water cooling systems, solar fountains, desktop fountains, arts and crafts, coffee makers, water dispensers, hydroponics, toothbrush cleaners, hot water circulation, swimming pool filtration, foot spas, massage bathtubs, automotive cooling loops, fuel dispensers, humidifiers, air conditioners, medical equipment, cooling systems, and bathroom appliances.

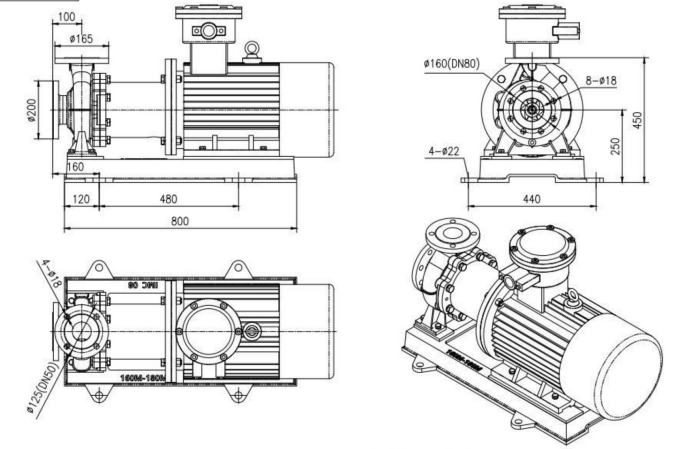

Magnetic Drive Pump real photo