Vertical Single-Stage Centrifugal Pump

- Gaotian

- Shanghai

- 15days

- 1500

Pump head: 4-85 meters

Pump flow rate: 4-1200 cubic meters per hour

Frequency: 50-60 Hertz

Voltage: 220V-380V

Motor power: 1.1 kW - 200 kW

Liquid temperature: -15°C to 110°C

Vertical Single-Stage Centrifugal Pump advantages

Direct integration into pipelines: They are designed for efficient liquid transportation and circulation, as well as boosting pressure.

Standard motor and mechanical seal: They come equipped with a standard motor (fully enclosed, air-cooled) and a reliable mechanical seal for longevity.

Modular design: The motor and pump can be separated, providing flexibility in maintenance without affecting the system.

Accessible pump section: The pump design allows for easy removal, facilitating repairs.

Impervious to impurities: Pipeline circulation pumps are less susceptible to damage from solids or debris in the conveyed fluids.

Quick maintenance: The top section is removable, enabling repairs without disrupting the entire pipeline network. The overall structure utilizes innovative, user-friendly disassembly components, even for replacing the mechanical seal, which does not necessitate motor disassembly.

Vertical Single-Stage Centrifugal Pump application

Vertical Single-Stage Centrifugal Pump (Circulation Pump / Pipeline Pump / Air Conditioning Cycle Pump)are primarily suited for operations at low pressures and high flow rates, typically employed in:

Domestic and commercial hot and cold water supply, as well as circulation networks.

Industrial water applications.

Basic home use scenarios.

HVAC refrigeration water loop circulation.

Heating systems within residential neighborhoods and apartments.

General water distribution systems.

Supporting boiler water circulation needs.

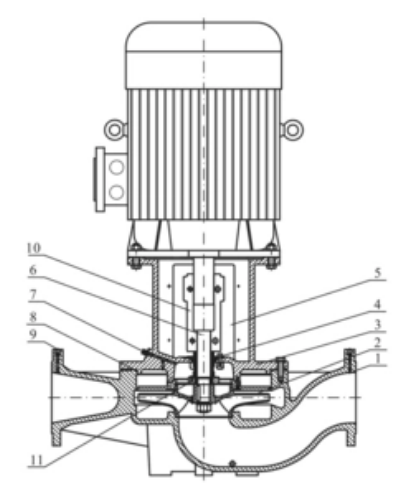

1. Pump housing

2. Impeller (or Blade wheel)

3. Nozzle (or discharge head)

4. Mechanical seal

5. Guard plate

6. Shaft

7. Discharge pressure release assembly

8. "O"-ring

9. Nut or Screw plug

10. Coupling

11. Bearing ring (or support ring)