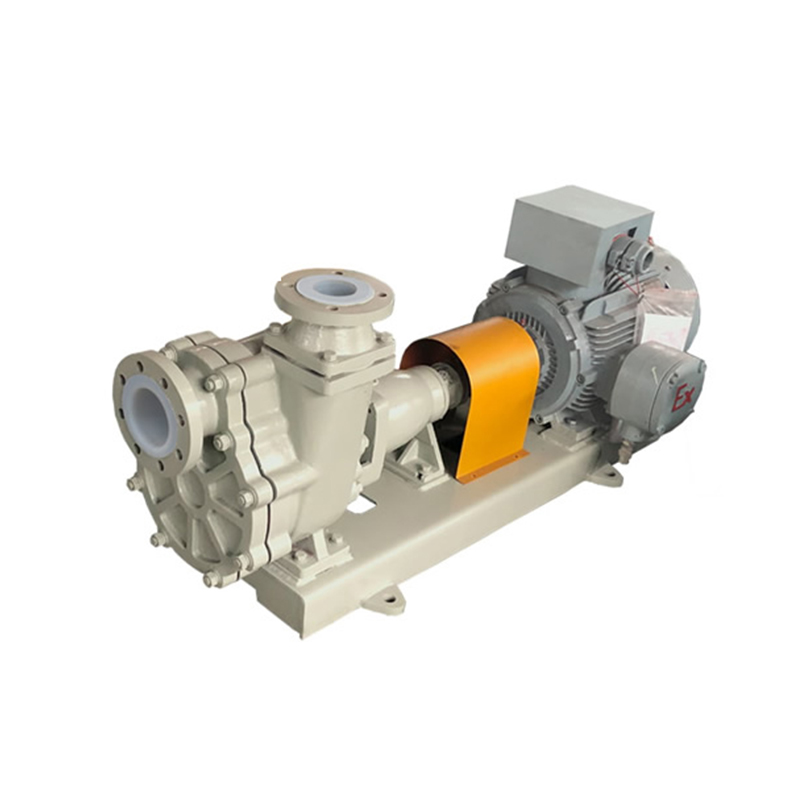

Plastic Lining Acid Transfer Pump

- Gaotian

- Shanghai

- 15days

- 1500

Plastic Lining Acid Transfer Pump is designed and manufactured according to standards and combining non-metallic pump processing technology. Plastic Lining Acid Transfer Pump body is made of a metal shell lined with polytetrafluoroethylene (F46), and the pump cover, impeller, and shaft sleeve are all made of metal inserts wrapped in fluoroplastics and sintered and molded. The shaft seal uses a Teflon-filled material, and the inlet and outlet are both reinforced with cast steel bodies. The shaft seal uses an externally mounted four-oxygen corrugated pipe mechanical seal, which has multiple layers of protection and extends the service life of the mechanical seal. For dry conveying media with impurity particles, a non-cooling water single end face hard-to-hard (silicon carbide to silicon carbide) mechanical seal can be used, so users need to consider the solid content in the medium when selecting the model.

Plastic Lining Acid Transfer Pump Application Range

The pump has the advantages of corrosion resistance, wear resistance, high temperature resistance, ** resistance, high mechanical strength, stable operation, reasonable structure, strict and reliable sealing performance, easy disassembly and maintenance, and long service life. It is widely used in petrochemical, metallurgy, synthetic fiber, pharmaceutical, food, brewing and other industrial sectors. It is used for conveying various acids, alkalis, salts, oils, beverages, chemical solvents.

Plastic Lining Acid Transfer Pump widely used in the transportation of corrosive liquids in the production processes of petroleum, chemical industry, acid and alkali production, smelting, rare earth, pesticides, dyes, pharmaceuticals, papermaking, electroplating, electrolysis, pickling, radio, chemical foils, research institutions, national defense industry, especially suitable for the transportation of high temperature, strong acids and alkalis, organic solvents, and valuable liquids.

Plastic Lining Acid Transfer Pump Design features

1. Plastic Lining Acid Transfer Pump is a new type of industrial pump with strong self-priming performance, designed and developed based on the IS02858/GB5662/DIN24256 international standard, combining the performance of centrifugal pump and self-priming centrifugal pump, and its technical indicators have reached the advanced level of similar products at home and abroad.

2. The standard shaft seal is an externally mounted single end face bellows mechanical seal, and optional materials for the sealing surface include: silicon carbide, hard alloy, etc. Double end face mechanical seal and internally mounted single end face mechanical seal can be optional according to requirements to meet various working conditions.

3. The internationally standardized back-pull-out design requires no disassembly of the pipeline, making maintenance convenient.

4. Horizontal installation, low vibration, low noise, stable operation, internationally standardized design, interchangeable with standard centrifugal pumps, facilitating user replacement and use.

5. Particularly suitable for low-level tank suction conditions, no need to equip a bottom valve during installation, and the self-priming height ranges from 1-5 meters. It has a larger gas-liquid separation chamber, unobstructed reflux channel, and advanced check valve design at the inlet to prevent liquid backflow after the pump stops. The sealing of the high and low pressure zones of the pump is reliable, significantly shortening the self-priming time, and greatly improving the self-priming performance with strong imported suction. The pump body is designed with liquid filling and draining holes to meet the needs of different working conditions to the maximum extent.

Plastic Lining Acid Transfer Pump Technical Parameters

Flow rate: 3.5~120m3/h;

Head: 5~80m;

Speed: 1450, 2900r/min;

Power: 0.75~110kw;

Inlet diameter: 32~100mm;

Outlet diameter: 25~80mm;

Operating temperature: -20~120°C, using new temperature-resistant materials can reach up to 180°C.

Plastic Lining Acid Transfer Pumpactual photo