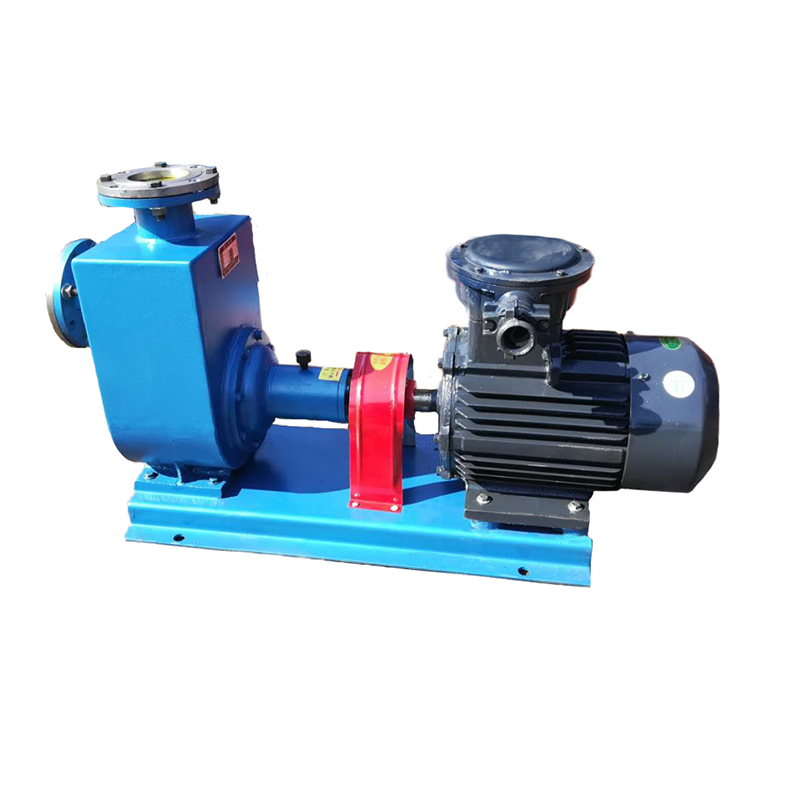

Self Priming Centrifugal Oil Pump

- Gaotian

- Shanghai

- 15days

- 1500

Self-priming centrifugal oil pump, used for transporting petroleum products such as gasoline, diesel, kerosene, aviation fuel, etc., is an excellent cargo oil pump and suitable for the transportation of oil in land oil depots and oil tankers. It can also be used to transport seawater, fresh water, etc. After changing to use corrosion-resistant mechanical seals, it can transport chemical liquids.

Self Priming Centrifugal Oil Pump Product Features

1. Self Priming Centrifugal Oil Pump is a self-priming centrifugal pump with the advantages of simple structure, easy operation, smooth operation, easy maintenance, high efficiency, long service life, and strong self-priming ability. It does not require a bottom valve in the pipeline, and only needs to ensure that the pump body contains a certain amount of priming oil before operation. When used on oil tankers or water transport ships, it can also serve as a bilge pump with excellent bilge sweeping effect.

2. Self Priming Centrifugal Oil Pump is refined with high-quality materials and uses hard alloy mechanical seals, making it durable. There is no need to install a safety valve in the discharge pipeline or a bottom valve in the suction pipeline, simplifying the pipeline system and improving working conditions.

Self Priming Centrifugal Oil Pump Working Principle

There are many types of self-priming structures, among which the working principle of an external mixed self-priming pump is as follows: Before the water pump starts, the pump casing is filled with water (or the pump casing contains water itself). When the pump is started, the high-speed rotation of the impeller causes the water in the impeller channel to flow towards the volute casing, creating a vacuum at the inlet, which opens the check valve and allows air from the suction pipe to enter the pump, reaching the outer edge through the impeller channel. On the other hand, the water discharged by the impeller into the air-water separation chamber flows back to the outer edge of the impeller through left and right return water holes. The water returning through the left return water hole, under the action of pressure difference and gravity, shoots into the impeller channel and is crushed by the impeller, mixing with the air from the suction pipeline, and then flows towards the volute in the direction of rotation. It then converges with the water flowing from the right return water hole and flows along the volute. As the liquid constantly impacts the guide vanes in the volute casing and is continually crushed by the impeller, it is vigorously mixed with the air, forming an air-water mixture that constantly flows, preventing the separation of air and water. The mixture is separated from the volute outlet and enters the separation chamber through a short pipe. In the separation chamber, the air is separated and discharged through the outlet pipe, while the water continues to flow back to the outer edge of the impeller through the left and right return water holes, mixing with the air from the suction pipe. This process is repeated, gradually removing the air from the suction pipeline, allowing the water to enter the pump and completing the self-priming process.

The working principle of an internal mixed self-priming oil pump is the same as that of an external mixed self-priming pump, with the only difference being that the returned water does not flow to the outer edge of the impeller but to the inlet of the impeller. When starting an internal mixed self-priming pump, the reflux valve below the impeller must be opened to allow the liquid inside the pump to return to the impeller inlet. The water mixes with the air from the suction pipe under the high-speed rotation of the impeller, forming an air-water mixture that is discharged to the separation chamber. Here, the air is discharged while the water returns from the reflux valve to the impeller inlet. This process is repeated until the air is removed and the water is drawn in.

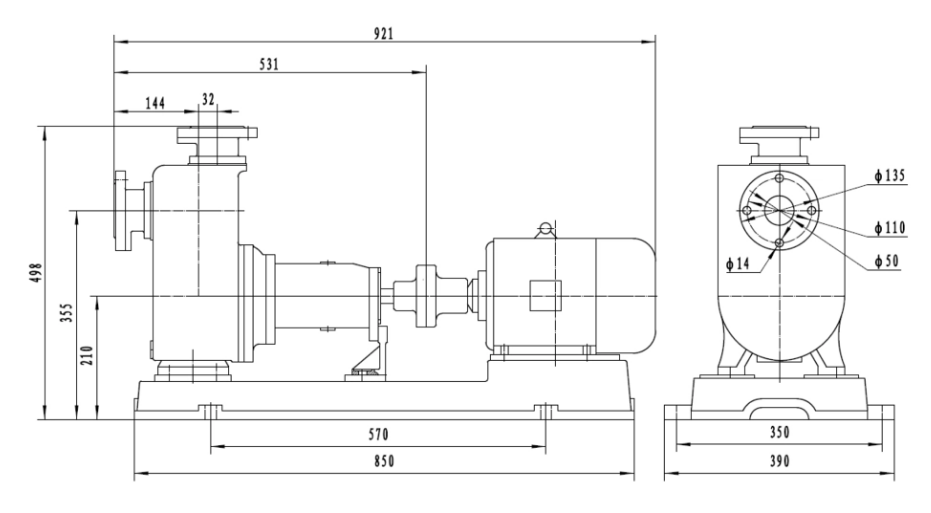

Self Priming Centrifugal Oil Pump section drawing