Vertical Immersion Pump

- Gaotian

- Shanghai

- 15days

- 3000

. Efficient pump design

. Minimal space requirement

. Robust safety features

. Wide application compatibility

Vertical Immersion Pump Introduction and Features

Our company has developed a new generation of XBD pipeline type medium and low pressure fire pump set products based on the original vertical multistage pump according to the latest standards for fire pumps. This series of pumps meet the requirements for fire pumps in terms of performance, structure, materials, and matching. Due to the use of an excellent hydraulic model, this series of pumps meets the requirements of users; the use of a vertical pump structure makes it highly efficient and with a wide performance range, as well as the advantage of saving floor space; the use of high-quality bearings and motors makes the pump operation safer, more reliable, with low noise and minimal vibration; the use of hydraulic balance axial force reduces balance drum, making the operation smoother; the pump has both mechanical seal and packing seal for shaft seals; it also features inlet and outlet water flange pipeline layout, high speed, and light weight, among other characteristics.

Vertical Immersion Pump Application Range

Suitable for various occasions such as residential buildings, hotels, office buildings, commercial buildings, factories, hospitals, and other places for fire water supply.

Vertical Immersion Pump Performance Range

Flow rate: 5~115L/s

Head: 20~230m

Power: 3~200KW

Vertical Immersion Pump Operating Conditions

1. Can transport clean water or non-corrosive media with physical and chemical properties similar to water, with insoluble solids not exceeding 0.1%.

2. Media temperature: -15°C~120°C.

3. Maximum working pressure: XBD pump: ≤2.5MPa, i.e. system pressure + head ≤2.5MPa, XBD(I) pump: ≤2.0MPa.

4. Ambient temperature not exceeding 40°C, relative humidity less than 95%.

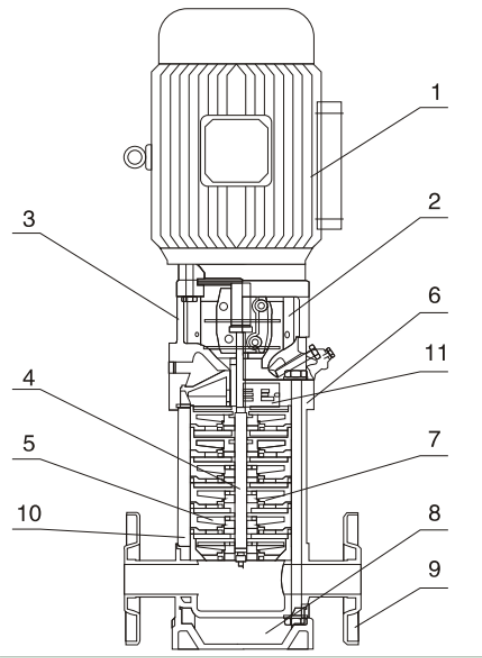

Vertical Immersion Pump structure

1. Motor

2. Coupling cover

3. Frame

4. Shaft

5. Impeller

6. Intermediate casing

7. Neck ring

8. Base plate

9. Pump body10. Outer sleeve

11. Mechanical seal