Vertical Inline Centrifugal Pump

- Gaotian

- Shanghai

- 15days

- 1500

Vertical Inline Centrifugal Pump is used for transporting clear water and other liquids with physical and chemical properties similar to water. Vertical Inline Centrifugal Pump is suitable for industrial and urban water supply and drainage, as well as for cold and hot water circulation, pressure boosting, and equipment matching, with a maximum temperature of T<80℃. Vertical Inline Centrifugal Pump is used for transporting liquids that do not contain solid particles and are corrosive, with viscosity similar to water. Vertical Inline Centrifugal Pump is suitable for sectors such as petroleum, chemical, power, papermaking, food, pharmaceuticals, and synthetic fibers, with a temperature range of 20°C to +120°C.

Vertical Inline Centrifugal Pump Product Introduction

● This series of products features high efficiency, energy saving, low noise, and reliable performance.

● Operating Conditions:Suction pressure ≤ 1.0MPa, or the maximum working pressure of the pump system ≤ 1.6MPa, which means the sum of the pump suction pressure and the pump head ≤ 1.6MPa. The static pressure test pressure of the pump is 2.5MPa. Please specify the system working pressure when placing an order. If the pump system working pressure is greater than 1.6MPa, it should be specified when placing the order so that cast steel materials can be used for the overcurrent parts and connections of the centrifugal pump during manufacturing.

● Ambient temperature < 40°C, relative humidity < 95%.

● The volume content of solid particles in the conveyed medium does not exceed 0.1% of the unit volume, and the particle size is < 0.2mm.

Vertical Inline Centrifugal Pump Product Advantages

● Vertical Inline Centrifugal Pumps are of vertical structure, with the same inlet and outlet diameters located on the same centerline. They can be installed in the pipeline like a valve, with a compact and attractive appearance, small footprint, and low construction costs. When equipped with a protective cover, they can be used outdoors.

● The impeller is directly mounted on the extended shaft of the motor, resulting in a short axial dimension and a compact structure. The pump and motor bearings are reasonably configured, effectively balancing the radial and axial loads generated during pump operation, ensuring smooth operation, low vibration, and low noise for the centrifugal pump.

● The shaft seal adopts a mechanical seal or a combination of mechanical seals, utilizing imported titanium alloy sealing rings, high-temperature resistant mechanical seals for medium-sized applications, and hard alloy materials for wear-resistant seals, effectively extending the service life of the mechanical seals.

● Convenient installation and maintenance, without the need to dismantle the pipeline system. Simply remove the pump coupling base nut to extract all rotor components.

●Inline multistage pump Can be operated in series or parallel according to the required flow rate and head.

●Inline multistage pump Can be installed vertically or horizontally according to the layout of the pipeline.

Note: If the medium contains fine particles, please specify when placing the order so that the manufacturer can use wear-resistant mechanical seals.

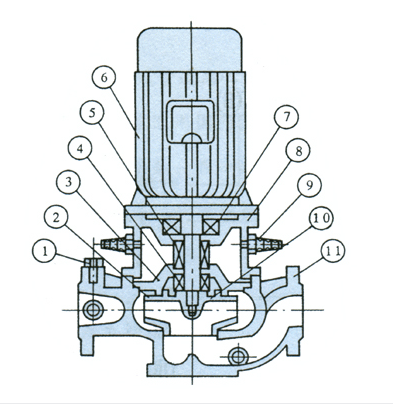

Vertical Inline Centrifugal Pump section drawing

1. Exhaust valve

2. Impeller

3. Pump cover

4. Mechanical seal

5. Mechanical seal

6. Motor

7. Bearing

8. Coupling base

9. Cooling water pipe

10. Impeller nut

11. Pump body