XBC Series Fire Fighting Electric Water Jockey Fire Pump

- Gaotian

- Shanghai

- 15days

- 1500

XBC Series Fire Fighting Electric Water Jockey Fire Pump Main features:

The electric pump serves as the primary firefighting pump, capable of automatically starting based on firefighting conditions.

Equipped with a constant pressure regulating pump to maintain stable network pressure.

The diesel engine pump serves as a backup firefighting pump, automatically starting in situations where there is no power supply for firefighting.

The diesel engine pump starts in the event of a malfunction in the electric pump.

XBC Series Fire Fighting Electric Water Jockey Fire Pump Usage

The XBC series diesel engine firefighting pump set is mainly used for boosting water in firefighting system pipelines. It is also suitable for industrial and urban water supply and drainage, boosting water in high-rise buildings, long-distance water supply, heating, bathrooms, boiler hot and cold water circulation, boosting water in air conditioning and refrigeration systems, and equipment matching, among other applications.

XBC Series Fire Fighting Electric Water Jockey Fire Pump Structure description

The XBC series diesel engine firefighting pump set is mainly composed of pumps, pump covers, impellers, shafts, sealing rings, shaft sleeves, and suspension bearing components according to customer requirements.

The pump body and pump cover of the XBC series diesel engine pump are divided from the back of the impeller, which is commonly known as a back-opening door structure. Its advantage lies in convenient maintenance, as during maintenance, the pump body, suction pipeline, discharge pipeline, and motor remain stationary, and only the intermediate connecting piece of the (extended) coupling needs to be removed to withdraw the rotor components for maintenance.

The pump's casing (i.e., pump body and pump cover) forms the pump's working chamber. The impeller, shaft, and rolling bearings constitute the pump's rotor. The suspension bearing components support the rotor components of the pump, and the rolling bearings bear the radial and axial forces of the pump.

To balance the axial forces of the pump, most pumps are equipped with sealing rings both in front and behind the impeller, and there are balance holes on the impeller back cover plate. However, some pumps have small axial forces, so there are no sealing rings or balance holes on the back of the impeller.

The axial sealing ring of the pump is composed of a packing gland, packing ring, and packing to prevent air intake or large amounts of leakage. If the pump's impeller is balanced, the cavity filled with soft packing communicates with the impeller inlet. If the liquid at the impeller inlet is in a vacuum state, air can easily enter along the surface of the shaft sleeve. Therefore, the packing cavity is equipped with a packing ring through the small hole on the pump cover to guide the pressure water in the pump chamber to the packing ring for sealing. If the pump's impeller does not have a balance hole, there is no air leakage problem because the liquid pressure on the back of the impeller is greater than atmospheric pressure, so the packing ring is not needed.

To prevent shaft wear, a shaft sleeve is installed to protect the shaft where it passes through the packing cavity. An O-ring seal is installed between the shaft sleeve and the shaft to prevent air intake or water leakage along the mating surface.

The pump is driven by an extended flexible coupling connected to the motor. The rotation direction of the pump, as seen from the drive end, is clockwise.

The inlet and outlet flanges of the pump are designed for a pressure of 1.6 MPa, making the pipeline matching convenient.

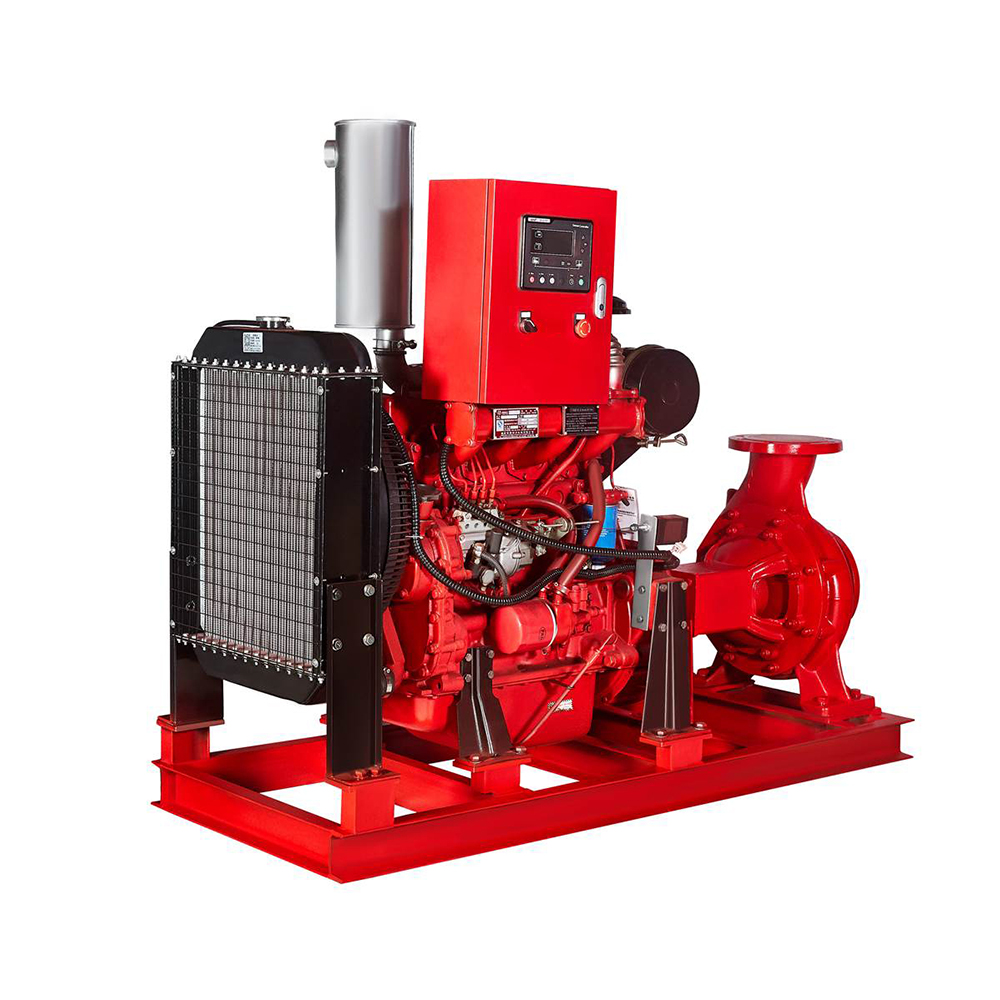

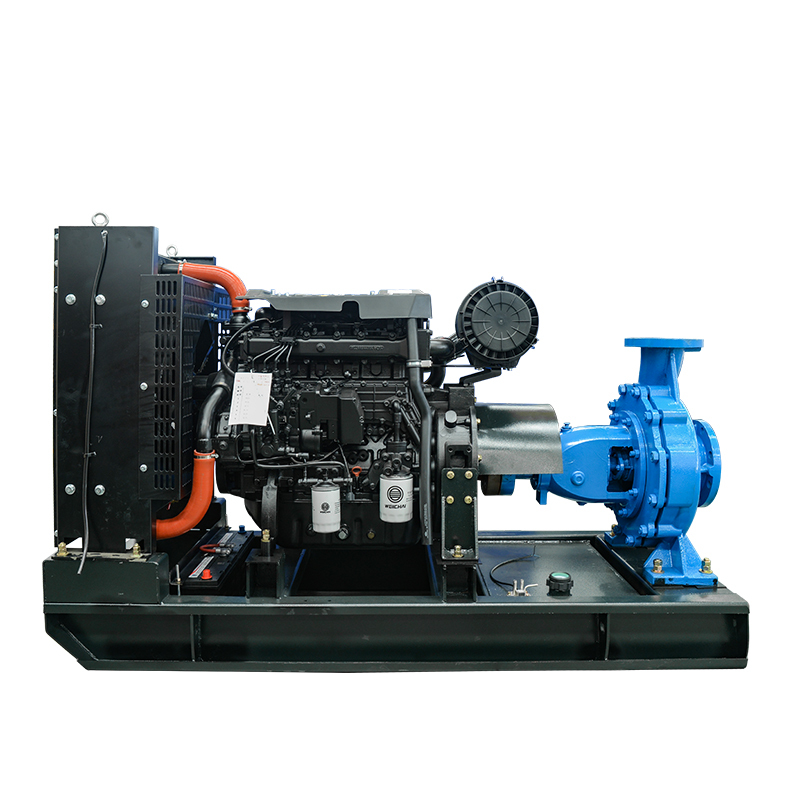

XBC Series Fire Fighting Electric Water Jockey Fire Pump Structure

1. Radiator

2. Diesel Engine

3. Coupling

4. Filter

5. Silencer

6. Water Pump

7. Battery

8. Base Seat