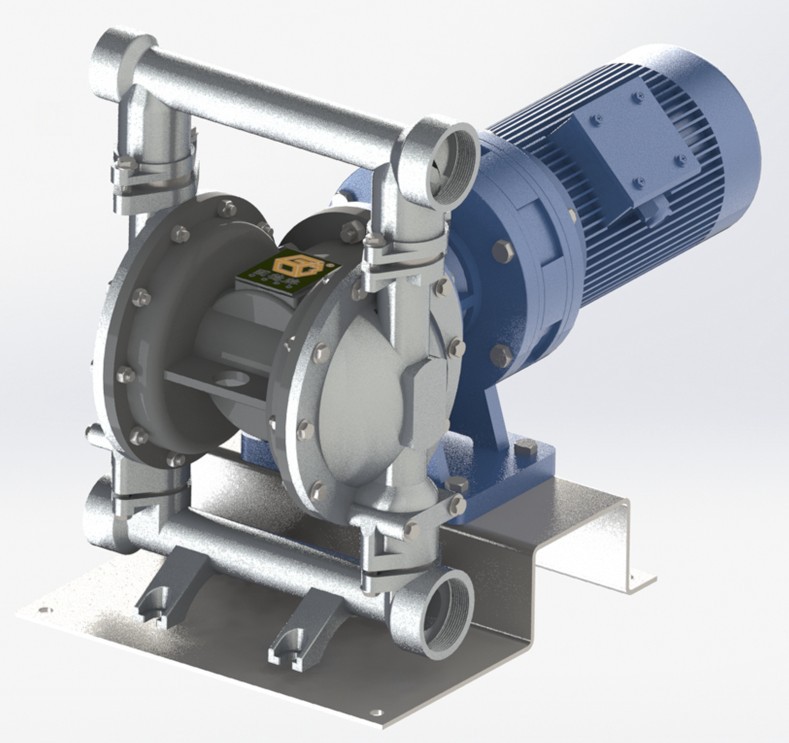

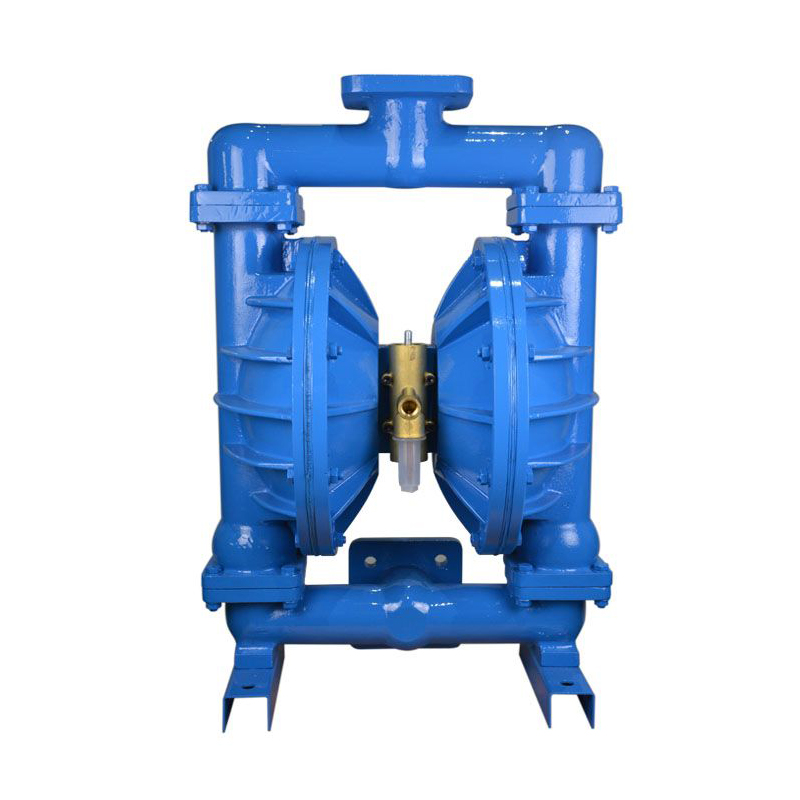

3 Inch Electric Diaphragm Pump

- Gaotian

- Shanghai

- 15days

- 1500

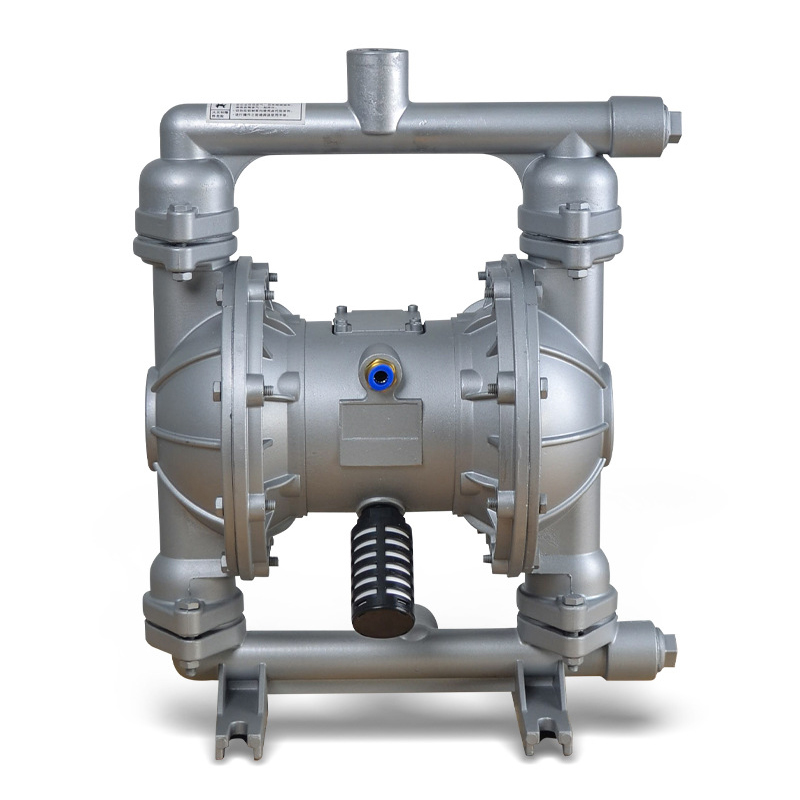

● Precision casting with smooth and tidy surface, and higher strength. The valve ball is further processed by a special machine for high roundness and good sealing performance.

● Precisely calculated diaphragm movement distance, reducing diaphragm stress and extending service life.

● Four-bolt connection design for good sealing performance, with actual dry suction of 4-7 meters. Three-stage upper and lower covers for flexible and convenient installation.

● Integral design of diaphragm guard block with excellent pressure resistance and high-temperature performance, widely used in the compressor industry.

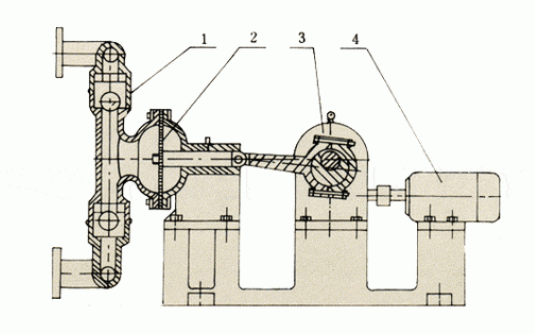

Electric diaphragm pumps, driven by cycloidal pinwheel reducers, utilize a crank-slider mechanism to drive dual diaphragms in reciprocating motion, thereby continuously suctioning and discharging liquid by alternately changing the working chamber volume. Additionally, in recent years, due to breakthroughs in diaphragm material, significantly extending the diaphragm's lifespan, they are increasingly replacing centrifugal pumps and screw pumps in industries such as petrochemicals, ceramics, and metallurgy.

Electric Diaphragm Pump Performance Features

No need for priming water; self-priming capability up to 7 meters.

Excellent passage performance, effortlessly handling particles, slurry, etc., with diameters below 10 millimeters.

As the diaphragm separates the conveyed medium from the transmission mechanical parts, there is absolutely no external leakage of the medium. Moreover, the pump itself has no shaft seal, significantly extending its service life. Depending on the conveyed medium, diaphragms can be made of materials such as neoprene rubber, nitrile rubber, fluoro rubber, and tetrafluoroethylene, fully meeting different customer requirements.

The pump body material flow section can be made of cast iron, stainless steel, or aluminum alloy, while the motor can be either standard or explosion-proof, according to user requirements.

Electric Diaphragm Pump Main Applications

1. Various highly toxic, flammable, and volatile liquids.

2. Various strong acids, alkalis, and corrosive liquids.

3. Can convey media with temperatures up to 150°C.

4. Used as a pre-pressurization device for various filter presses.

5. Hot water recovery and circulation.

6. Oil tankers, oil depots, and oil loading and unloading.

7. Pumping of pickles, jams, mashed potatoes, chocolates, etc.

8. Pumping of paints, resins, and pigment adhesives.

9. Various ceramic glazes, cement grouts, mortars, and slurry.

10. Various rubber latex, organic solvents, and fillers.

11. Used for clearing sewage and residual oil from oil tankers and barges.

12. Hops and yeast slurry, syrup, molasses.

13. Pumping of sewage, sediment in mines, tunnels, and sewers.

14. Conveying various special media.

Electric Diaphragm Pumpanimated GIF