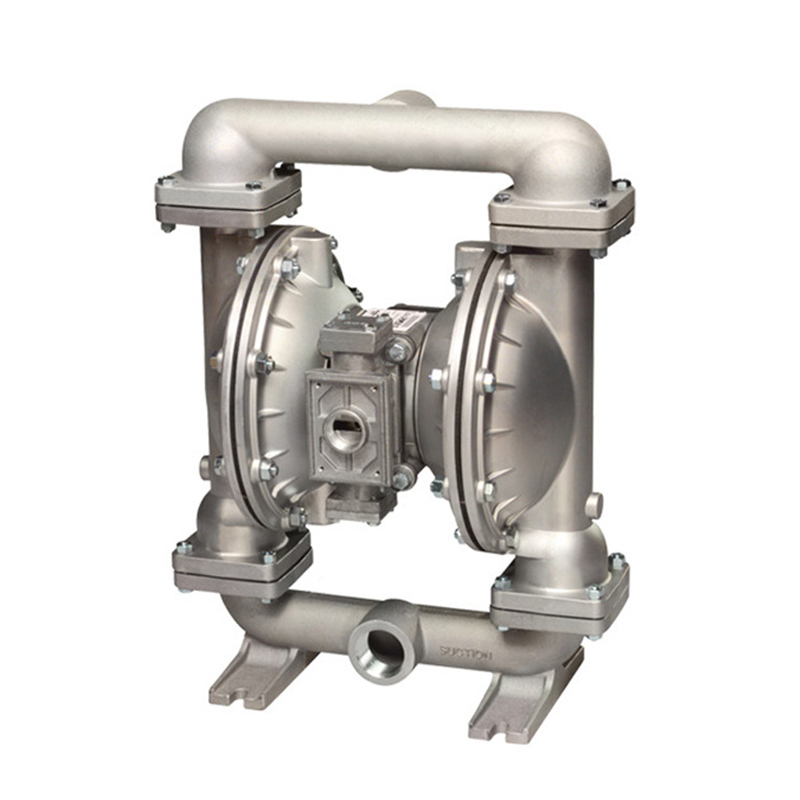

Stainless Steel Diaphragm Pump

- Gaotian

- Shanghai

- 15days

- 1500

Stainless Steel Diaphragm Pump is an improvement based on the QBY pneumatic diaphragm pump, incorporating an internal air distribution valve. With a simpler structure, increased flow rate, and higher lift, it offers stable performance. It combines the advantages of self-priming pumps, submersible pumps, shielded pumps, slurry pumps, and impurity pumps. Widely used in industries such as chemical, petroleum, pharmaceutical, mining, papermaking, cement plants, steel plants, power plants, and coal processing industries.

Features of Stainless Steel Diaphragm Pump

The stainless steel pneumatic diaphragm pump can handle both fluid and dry powder, as well as some difficult-to-move media. It combines the advantages of self-priming pumps, submersible pumps, shielded pumps, slurry pumps, and impurity pumps.

1. No need for water filling, with a high suction lift of up to 7m and a head of up to 70m, and an outlet pressure of ≥ 0.8Mpa.

2. Wide flow passage, good passability, allowing for the pumping of large particles up to 9.4mm in diameter without significant pump wear when handling slurry or impurities.

3. The head and flow rate can be adjusted by the air supply pressure (air pressure between 0.1-0.84Mpa).

4. Operating temperature range: 5-65°C; media transport range (-20°C-150°C).

5. The pump has no rotating parts, and the diaphragm isolates the pumped medium from the moving parts and working medium of the pump, preventing leakage of the transported medium. Therefore, when pumping toxic, volatile, or corrosive media, it will not cause environmental pollution or endanger personal safety.

6. No electricity is required, making it safe and reliable for use in flammable and explosive environments.

7. Can operate submerged in the medium.

8. Easy to use, reliable operation, and simple start and stop with the opening and closing of the gas valve. Even if there is no medium running for a long time or sudden shutdown due to unexpected circumstances, the pump will not be damaged. If overloaded, the pump will automatically stop, with self-protection capabilities. It will automatically restart when the load returns to normal.

9. Simple structure, easily replaceable wearing parts. The pump's simple structure and easy installation and maintenance ensure that the transported medium does not come into contact with the air distribution valve, connecting rod, and other moving parts, unlike other types of pumps where performance gradually declines due to wear on rotors, pistons, gears, blades, etc.

10. Can handle relatively viscous liquids (viscosity below 10,000 centipoise).

11. The pump does not require oil lubrication, and even if operated without load, it will not be affected, which is a major feature of this pump.

Stainless Steel Diaphragm Pump Features

Easy maintenance and reduced internal volume to minimize waste and facilitate cleaning.

Stainless steel bolts are corrosion-resistant and provide proper positioning for easy reassembly. Precision-matched components.

Wear-resistant end bearings ensure proper positioning of the valve stem, making replacement simple.

Protected discharge outlet

The discharge outlet adopts a common end to prevent vaporized liquid from corroding the air motor seals inside the chamber. It facilitates the blanking function for tank loading or unloading operations.

Robust external structure

Corrosion-resistant structure prevents leaks and ensures clean fluid replacement. The central components are aluminum with an epoxy coating. Corrosion-resistant central parts use 316 stainless steel material.

Fluid compatibility

The housing materials available include aluminum, stainless steel, ductile iron, polypropylene, conductive acetal, or tetrafluoroethylene polymer. Reasonably designed seals.

Diaphragms can be tightly locked to provide positive liquid sealing.

Reliable heavy-duty diaphragm plate clamping can eliminate all leakage and dislodgement, avoiding downtime due to malfunctions. Long-lasting valve stem design.

The 300 series stainless steel valve stem has a longer service life and excellent corrosion resistance even in humid air.

Selection of elastic materials

Various options for valve seats and balls ensure fluid compatibility and reliable sealing, resulting in longer service life and better suction height.

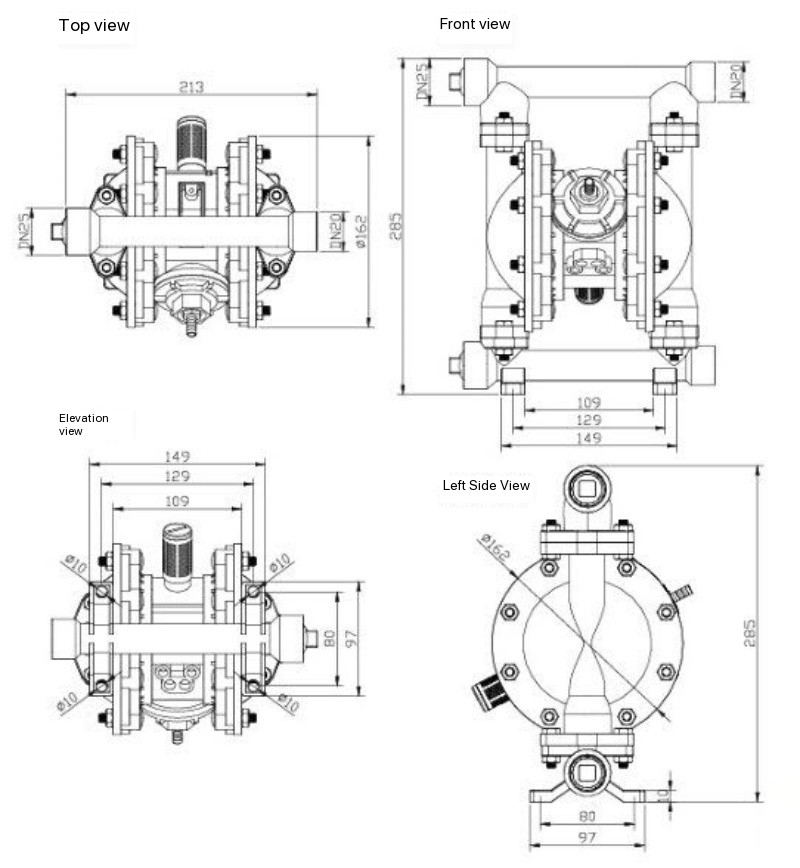

Stainless Steel Diaphragm Pump section drawing