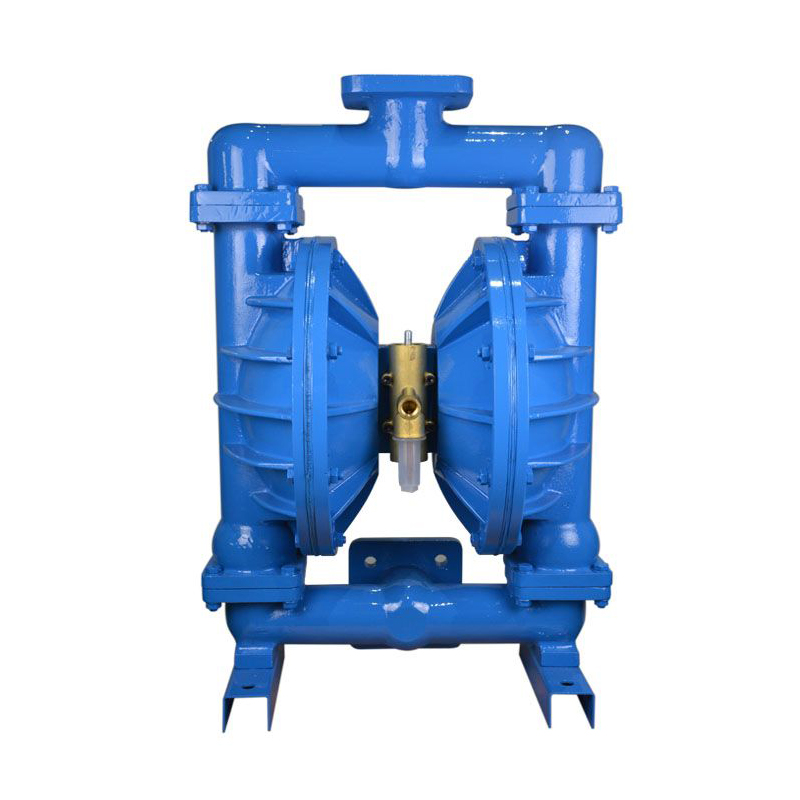

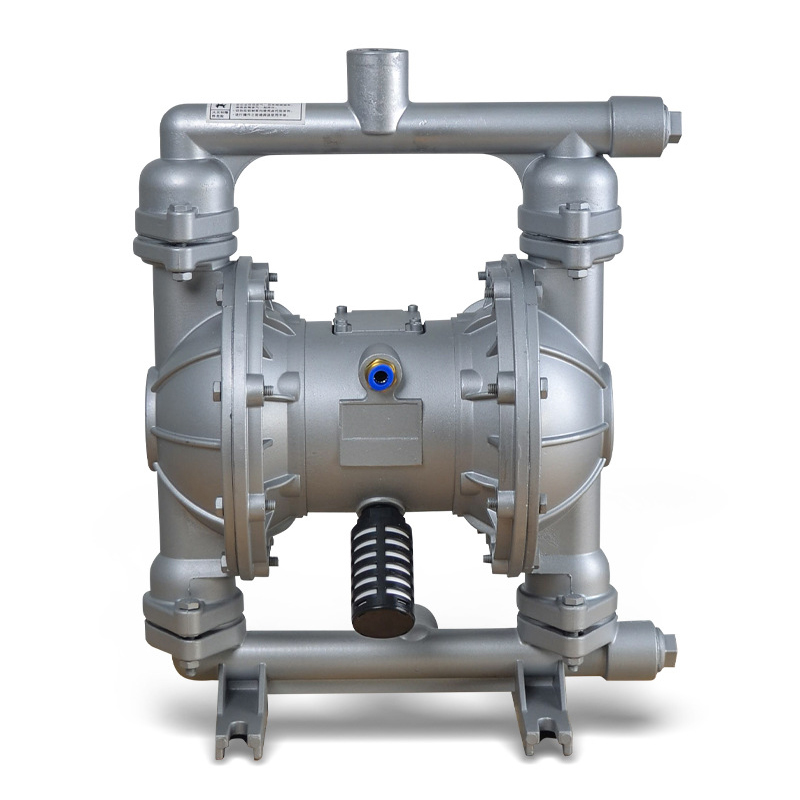

Air Driven Diaphragm Pump

- Gaotian

- Shanghai

- 15days

- 1500

Performance Advantages of Air Driven Diaphragm Pump:

1. Flow + Pulsation and Gas Consumption = Performance

2. Bolted Construction and Wide Material Selection

3. Modular Structure for Easy Maintenance

4. Spark-Free and Heatless Operation

5. User-Friendly Operation

6. Low Shear Force on Materials:

7. Patented Air Valve Design for Reliability

Air driven diaphragm pumps offer a host of performance advantages, including efficient flow characteristics, versatile material compatibility, ease of maintenance, safety features, user-friendly operation, low shear force on materials, and patented reliability-enhancing designs. These qualities make them indispensable equipment for various fluid transfer applications across industries.

Advantages of Air Driven Diaphragm Pump

1. Versatile Applications

Air driven diaphragm pumps offer versatility in applications across various industries. From transferring fluids in chemical processing plants to pumping viscous materials in food production, these pumps are adaptable to a wide range of pumping needs.

2. Efficient and Reliable Operation

With their simple yet robust design, air driven diaphragm pumps provide efficient and reliable operation. The air-driven mechanism ensures consistent performance, making these pumps suitable for continuous and demanding pumping tasks.

3. Superior Safety Features

Air diaphragm pumps prioritize safety with features like leak-proof construction and corrosion-resistant materials. These pumps are suitable for handling hazardous or corrosive fluids, providing peace of mind to operators and ensuring a safe working environment.

4. Self-Priming Capability

One of the key advantages of air diaphragm pumps is their self-priming capability. They can evacuate air from the suction line and start pumping without the need for external priming, making them ideal for applications where suction lift is required.

5. Easy Maintenance and Serviceability

Air diaphragm pumps are designed for easy maintenance and serviceability. With fewer moving parts and accessible components, routine maintenance tasks such as diaphragm replacement or valve inspection can be performed quickly, minimizing downtime and reducing operating costs.

6. Energy Efficiency

Compared to other types of pumps, air diaphragm pumps are energy-efficient. They operate on compressed air, eliminating the need for electricity or fuel-powered motors. This not only reduces energy consumption but also lowers operating expenses over the pump's lifecycle.

7. Portable and Compact Design

Air driven diaphragm pumps feature a portable and compact design, making them suitable for mobile or remote applications. Their lightweight construction and minimal footprint allow for easy transportation and installation in various settings, including construction sites or remote industrial facilities.

In summary, air driven diaphragm pumps offer a multitude of advantages, including versatility, efficiency, safety, self-priming capability, ease of maintenance, energy efficiency, and portability. These qualities make them indispensable equipment in numerous industries for fluid transfer and pumping operations.

Air Driven Diaphragm Pump Applicable industries

Chemical industry: acids, alkalis, solvents, suspensions, dispersion systems.

Petrochemical industry: crude oil, heavy oil, grease, mud, sludge, etc.

Coating industry: resins, solvents, pigments, paints, etc.

Daily chemical industry: detergents, shampoos, emulsions, lotions, hand creams, surfactants.

Ceramic industry: mud, porcelain slurry, lime slurry, clay slurry.

Mining industry: coal slurry, ore pulp, mud, mortar, pharmaceutical slurry, lubricating oil.

Water treatment: lime slurry, soft precipitate, sewage, chemicals, wastewater, etc.

Food industry: liquid and semi-solid substances, chocolate, brine, vinegar, syrup, vegetable oil, soybean oil, honey, animal blood.

Beverage industry: yeast, syrup, concentrates, gas-liquid mixtures, wine, fruit juice, corn syrup, etc.

Pharmaceutical industry: solvents, acids, alkalis, plant extracts, ointments, plasma, and various pharmaceutical liquids.

Paper industry: adhesives, resins, paints, inks, pigments, hydrogen peroxide, etc.

Electronics industry: solvents, plating solutions, cleaning solutions, sulfuric acid, nitric acid, waste acids, corrosive acids, polishing solutions.

Textile industry: dye chemicals, resins, adhesives, etc.

Construction industry: cement slurry, ceramic tile adhesive, rock slurry, ceiling paint, etc.

Automotive industry: polishing emulsions, oils, coolants, automotive primers, oil emulsions, varnishes, varnish additives, degreasers, paints.

Furniture industry: adhesives, varnishes, dispersion systems, solvents, pigments, white glue, epoxy resin, starch adhesives.

Metallurgy, casting, and dyeing industry: metal slurry, hydroxide and carbide slurry, dust washing slurry, etc.

Performance Advantages of Air Driven Diaphragm Pump:

1. Flow + Pulsation and Gas Consumption = Performance:

The performance of an air-driven diaphragm pump is defined by its flow rate, pulsation characteristics, and gas consumption. These factors collectively contribute to its overall efficiency and effectiveness in fluid transfer applications.

2. Bolted Construction and Wide Material Selection:

Featuring a bolted construction and a wide range of material options, air diaphragm pumps ensure compatibility with various fluids and prevent leaks. This robust design enhances fluid compatibility and leak prevention, ensuring reliable operation in diverse environments.

3. Modular Structure for Easy Maintenance:

The modular design of air diaphragm pumps reduces the number of components, making maintenance easier and more cost-effective. By minimizing maintenance time and costs, this modular structure enhances operational efficiency and prolongs the pump's lifespan.

4. Spark-Free and Heatless Operation:

Air diaphragm pumps operate without generating sparks, even when grounded, and produce no heat during operation. This feature eliminates the risk of sparks igniting flammable substances and prevents the pump from overheating, ensuring safe and reliable operation in hazardous environments.

5. User-Friendly Operation:

Air diaphragm pumps, such as the Ingersoll Rand pneumatic diaphragm pump, are easy to operate and maintain. They offer self-priming capabilities and can adjust pressure or fluid pressure to meet varying flow requirements, enhancing operational flexibility and convenience.

6. Low Shear Force on Materials:

The suction force generated during operation of air diaphragm pumps results in minimal shear force on materials, making them suitable for transferring unstable substances without causing excessive agitation or damage.

7. Patented Air Valve Design for Reliability:

Air diaphragm pumps feature a patented air valve design that eliminates dead spots and prevents the exhaust port from freezing. This innovative design ensures reliable and continuous operation, even in demanding environments.

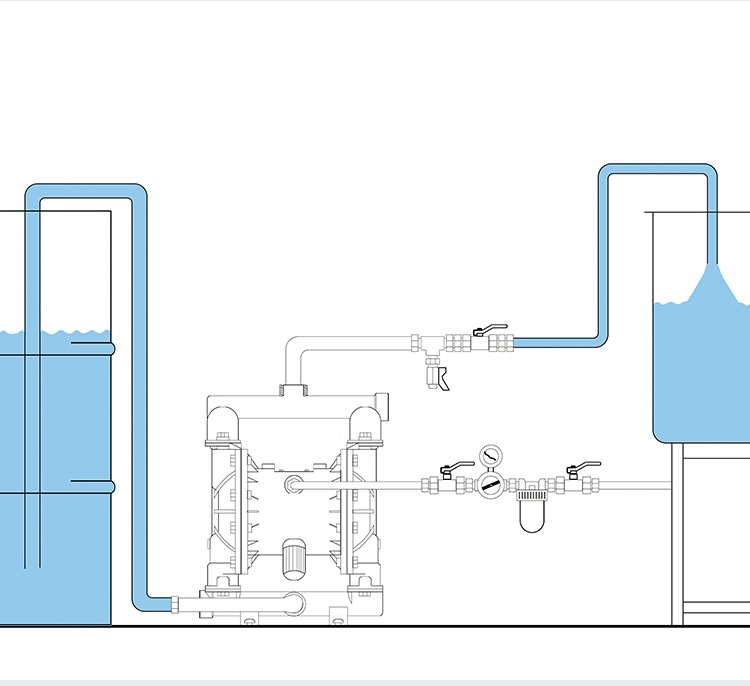

Air Driven Diaphragm Pump section drawing